Preparation method of toughened high temperature tolerant polyester material namely poly(1,4-cyclohexylenedimethylene) terephthalate

A technology of cyclohexanedimethanol ester and polyterephthalic acid, which is applied in the field of polymer material production, can solve the problems that the performance and function of polymer materials are difficult to meet the needs of the industry, and achieves improved branching rate and heat resistance. The effect of improving the thermal conductivity and increasing the toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

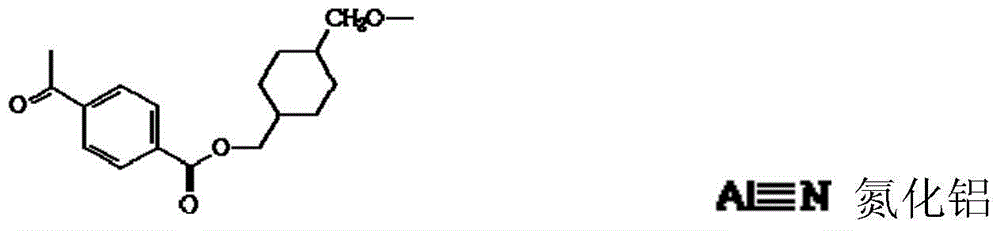

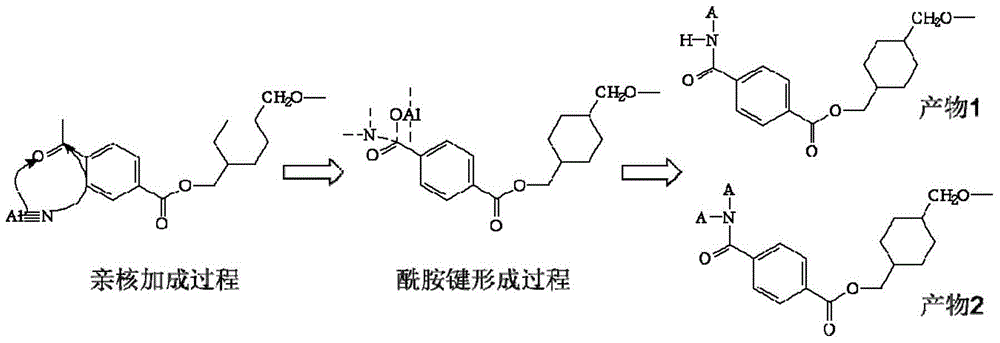

Method used

Image

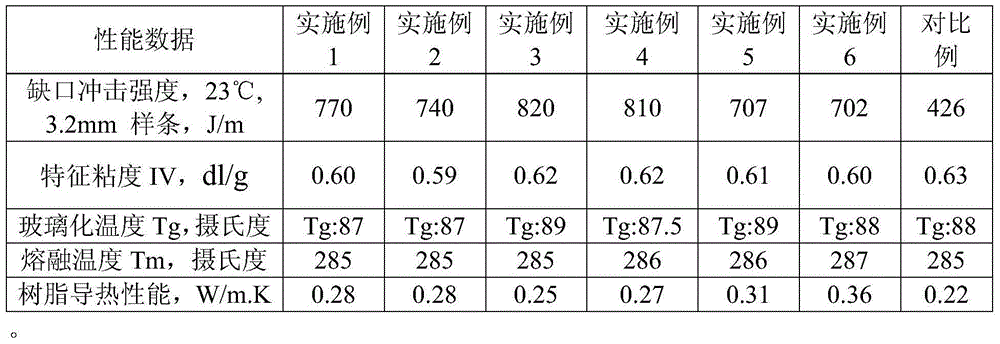

Examples

Embodiment 1

[0031] A preparation method of toughened and high temperature resistant polyester material poly-1.4 cyclohexane dimethanol terephthalate, comprising the following steps:

[0032] (1) Beating: Purified terephthalic acid (PTA, commercially available) and 1,4 cyclohexanedimethanol (CHDM, commercially available) were weighed in a molar ratio of 1:1 and fed into the polymerization kettle at one time , stir and mix evenly, and then add the dibutyltin oxide solution with a mass concentration of 1% (prepared by dibutyltin oxide and solvent ethylene glycol) into the reaction system according to the dose propeller step by step (the addition is completed in 10 minutes), The addition amount of n-tetrabutyl titanate was 8 ppm, and it stirred at 55 degreeC for 3 hours.

[0033] (2) Esterification: the polymerization kettle was pressurized to 0.3MPa, heated to 260°C, reacted for 70 minutes, then depressurized to 0.04MPa, controlled at 270°C, reacted for 30 minutes, and then added thermal sta...

Embodiment 2

[0037] A preparation method of toughened and high temperature resistant polyester material poly-1.4 cyclohexane dimethanol terephthalate, comprising the following steps:

[0038] (1) Beating: Purified terephthalic acid (PTA, commercially available) and 1,4 cyclohexanedimethanol (CHDM, commercially available) were weighed in a molar ratio of 1:2 and fed into the polymerization kettle at one time , stir and mix evenly, then add 4% ethylene glycol antimony solution (prepared with ethylene glycol antimony and solvent ethylene glycol) into the reaction system step by step according to the dose propeller (the addition is completed in 25 minutes), titanic acid The amount of n-tetrabutyl ester added was 12 ppm, and the mixture was stirred at 65°C for 1 hour.

[0039] (2) Esterification: the polymerization kettle was pressurized to 0.4MPa, heated to 280°C, reacted for 50 minutes, then depressurized to 0.06MPa, controlled at 280°C, reacted for 15 minutes, and then added thermal stabiliz...

Embodiment 3

[0043]A preparation method of toughened and high temperature resistant polyester material poly-1.4 cyclohexane dimethanol terephthalate, comprising the following steps:

[0044] (1) Beating: Purified terephthalic acid (PTA, commercially available) and 1,4 cyclohexanedimethanol (CHDM, commercially available) were weighed in a molar ratio of 1:1.5 and fed into the polymerization kettle at one time , stir and mix evenly, and then add the n-tetrabutyl titanate solution with a mass concentration of 2% (prepared by n-tetrabutyl titanate and solvent ethylene glycol) into the reaction system step by step according to the dose propeller (the addition is completed in 20 minutes), The addition amount of n-tetrabutyl titanate was 10 ppm, and the mixture was stirred at 60° C. for 2 hours.

[0045] (2) Esterification: the polymerization kettle was pressurized to 0.35MPa, heated to 270°C, reacted for 60 minutes, then depressurized to 0.05MPa, controlled at 275°C, reacted for 20 minutes, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com