Polypropylene anti-counterfeiting film and preparation method thereof

A polypropylene and film technology, applied in the field of polypropylene anti-counterfeiting film and its preparation, can solve the problems of increasing processing steps, not having anti-counterfeiting function, affecting product appearance, etc., achieving good bonding force, realizing authenticity identification and traceability, and easy The effect of processing and mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1~A40

[0043] Embodiments A1~A40 and comparative examples B1~B4: preparation of anti-counterfeiting masterbatch

[0044] Weigh the carrier resin, fluorescent powder, coding substances and additives according to the proportions shown in Table 1~5, pour them into a high mixer and mix evenly, melt them in a twin-screw extruder at 200~300°C, extrude and granulate , to prepare anti-counterfeiting masterbatch.

[0045] .

Embodiment 1~40 and comparative example 1~6

[0046] Examples 1-40 and Comparative Examples 1-6: Preparation of polypropylene anti-counterfeiting film

[0047] A kind of preparation method of polypropylene anti-counterfeiting film, its raw material formula is as shown in table 6~10, and its preparation method comprises the following steps:

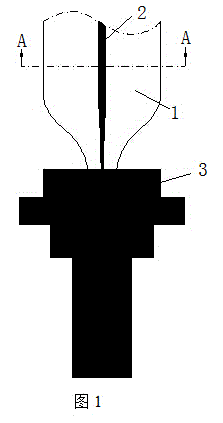

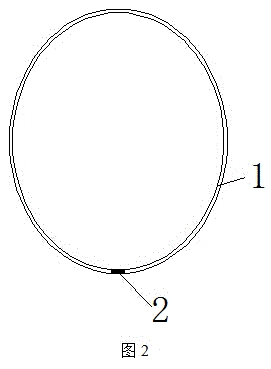

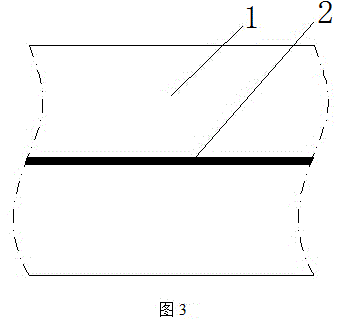

[0048] Weigh each component by weight, and use two large and small extruders to extrude polypropylene, processing aids and the anti-counterfeiting masterbatches prepared in Tables 1 to 5 to the co-extrusion head, polypropylene and processing After the additives are mixed evenly, they are extruded from the large extruder, and the anti-counterfeit masterbatch is extruded from the small extruder. After extruding the two-color foam tube, it is blown, drawn, and wound to obtain a polypropylene anti-counterfeiting film with anti-counterfeiting strips. ; Wherein, the barrel temperature of the two large and small extruders is equally divided into three sections for control, followed by feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com