Method for preparing magnesium matrix composite semisolid slurry by adopting ultrasonic in situ synthesis

A semi-solid slurry and composite material technology, applied in the direction of improving process efficiency, etc., can solve the problems of low strength of magnesium alloy, limited application range, poor high temperature creep resistance, etc., to achieve fine solid particles and simple process , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

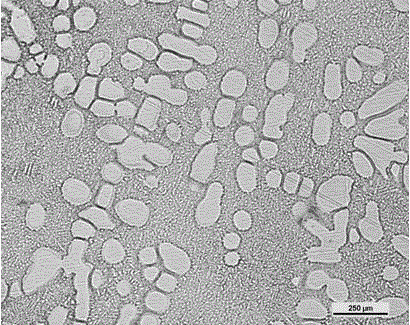

Embodiment 1

[0011] In this example, the AZ91 alloy (Al 9.163, Zn 0.538, Mn 0.218, Si 0.042, Fe 0.0028, Cu 0.0053, Be 0.0007, Ni 0.0056, the balance is Mg, mass fraction, the same below) is used as the matrix, and the bulk Mg The -Y master alloy is broken into small particles, wrapped in aluminum foil and preheated to 250°C for use. After the matrix alloy is melted and kept warm, add Mg-Y intermediate alloy, then adjust the furnace temperature to 850°C, turn off the power supply of the melting furnace, put the ultrasonic horn probe into the melt, and ultrasonicate the melt. After the ultrasound stops, let it stand still, cool down to 584°C, and use continuous ultrasonic method to ultrasonically vibrate the melt to prepare particle-reinforced Al 2 Y / AZ91 Magnesium-based composite material semi-solid slurry. In order to prevent the oxidation of the alloy, a covering agent is used in the preparation process (the main component and mass fraction of the covering agent are: KCl is 45%, MgCl 2 ...

Embodiment 2

[0013] In this example, the AZ61 alloy (Al 6.0, Zn 0.538, Mn 0.218, Si 0.1, Fe 0.005, Cu 0.005, Ni 0.05, Others 0.3, the balance is Mg, mass fraction, the same below) is used as the matrix, and the bulk The Mg-Y master alloy is broken into small particles, wrapped in aluminum foil and preheated to 250°C for use. After the matrix alloy is melted and kept warm, add Mg-Y intermediate alloy, then adjust the furnace temperature to 850°C, turn off the power supply of the melting furnace, put the ultrasonic horn probe into the melt, and ultrasonicate the melt. set, lower the temperature to 570 ° C, and use continuous ultrasonic method to ultrasonically vibrate the melt to prepare particle-reinforced Al 2 Y / AZ61 magnesium composite semi-solid slurry. In order to prevent the oxidation of the alloy, a covering agent is used in the preparation process (the main component and mass fraction of the covering agent are: KCl is 45%, MgCl 2 45%, CaF 2 5%, BaCl 2 5%) and through SF 6 and CO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com