High-purity antimony producing method by two-section fused salt electrolysis method

A technology of molten salt electrolysis and molten salt electrolyte, which is applied in the field of two-stage molten salt electrolysis to produce high-purity antimony, can solve the problems of complex equipment structure, limited purification effect, and high purification cost, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Break the industrial antimony ingots into irregular antimony blocks of about 3mm, add the broken antimony blocks and molten salt electrolyte into the electrolytic cell, use the anode method for electrolysis, turn on the heating device, raise the temperature to 750°C, and control the current density at 6650A / m 2 , after electrolysis for 3 hours, a product was obtained; a product was electrolyzed by cathodic method, the temperature was set to 700°C, and the cathodic current density was 1200A / m 2 , Electrolyzed for 3 hours to obtain a high-purity antimony product, which was determined by GDMS to have a purity of 99.99%.

Embodiment 2

[0028] Break the industrial antimony ingots into irregular antimony blocks of about 3mm, add the broken antimony blocks and molten salt electrolyte into the electrolytic tank, use the anode method for electrolysis, turn on the heating device, raise the temperature to 850°C, and control the current density at 6650A / m 2 , after 3 hours of electrolysis, a product was obtained; a product was electrolyzed by cathodic method, the temperature was set to 750°C, and the cathodic current density was 1200A / m 2 , Electrolyzed for 3 hours to obtain a high-purity antimony product, which was determined by GDMS to have a purity of 99.99%.

Embodiment 3

[0030] Break the industrial antimony ingots into irregular antimony blocks of about 3mm, add the broken antimony blocks and molten salt electrolyte into the electrolytic cell, use the anode method for electrolysis, turn on the heating device, raise the temperature to 900°C, and control the current density at 6650A / m 2 , after electrolysis for 3 hours, a product was obtained; a product was electrolyzed by cathodic method, the temperature was set to 800°C, and the cathodic current density was 1200A / m 2 , Electrolyzed for 3 hours to obtain a high-purity antimony product, which was determined by GDMS to have a purity of 99.99%.

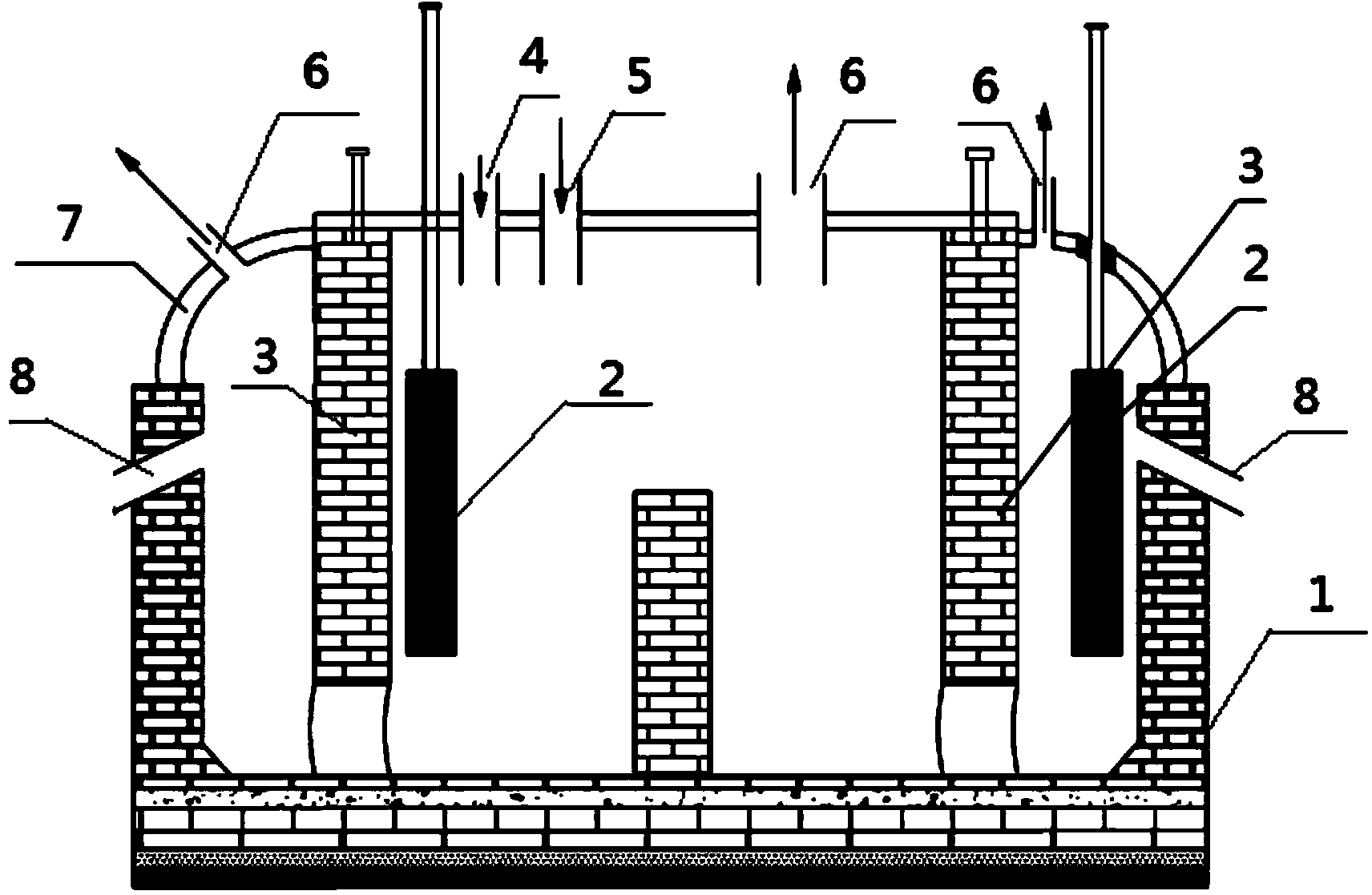

[0031] Such as figure 1 As shown, the electrolytic cell used in a method for producing high-purity antimony by a two-stage molten salt electrolysis method of the present invention includes a cell body 1, a cover plate 7, two groups of first electrodes 2 and second electrodes 3, and a flue gas outlet 6 , chute 8, coarse antimony feed port 4, electrolyte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com