High pressure centrifugal slurry pump

A technology of centrifugal and slurry pumps, which is applied in the direction of non-variable pumps, non-volume pumps, pumps, etc. It can solve the problems of complex maintenance and management, high shaft seal pressure, and many workbenches, so as to improve operating conditions , Reduce the force, the effect of fewer seats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

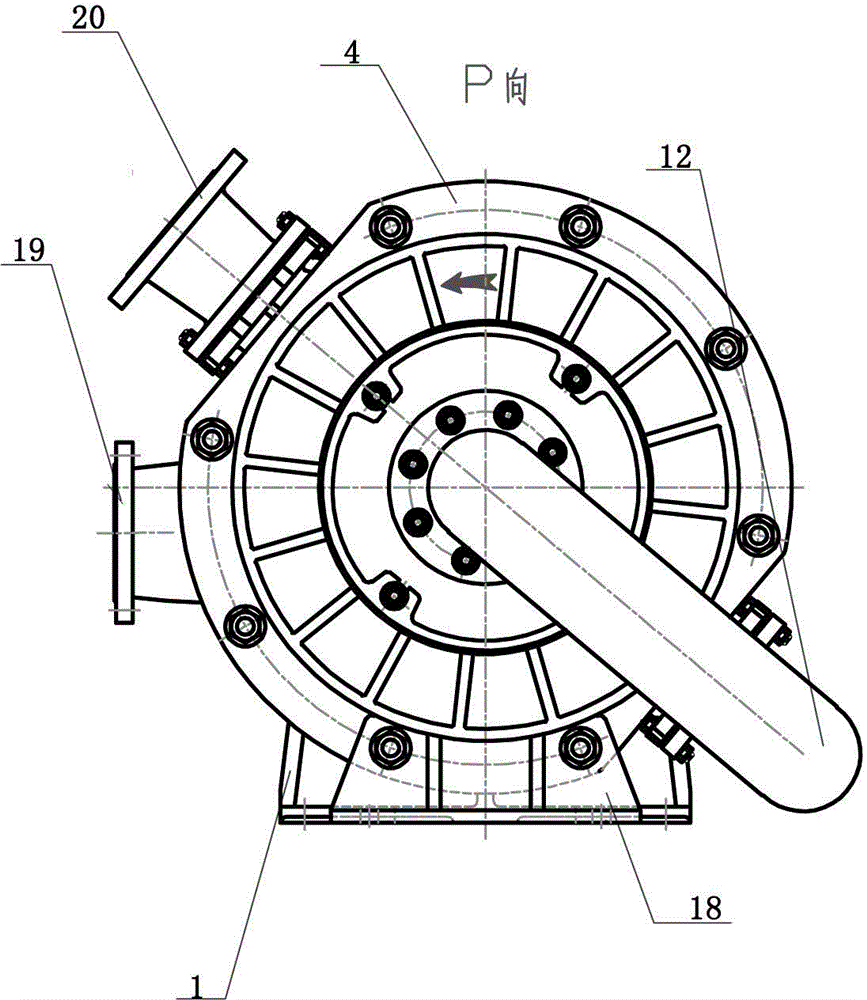

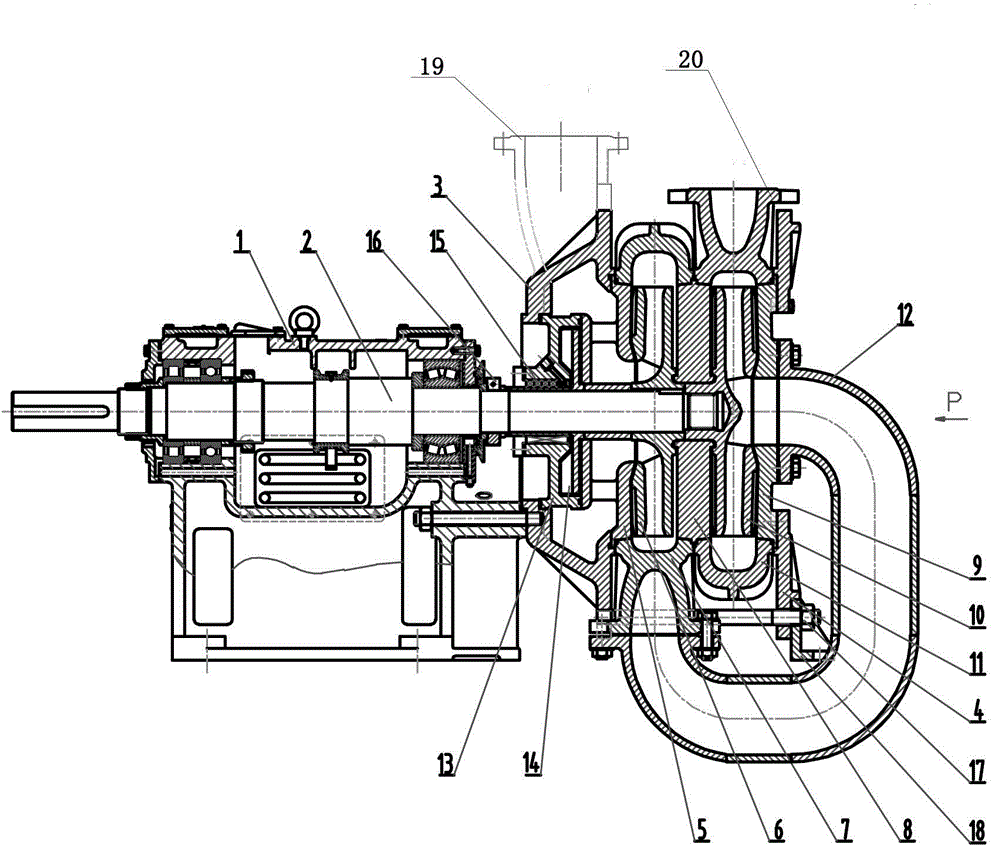

[0025] as attached figure 1 , 2 The embodiment of the present invention shown is a double-impeller high-pressure centrifugal slurry pump, and its bracket part 1 has the function of fixing and supporting the whole machine. The function of shaft 2 is to transmit torque, connect rotating parts, such as impeller A6, impeller B10 and auxiliary impeller 14, etc., and drive the impeller to do work on the slurry.

[0026] The joint plate 3 connects the bracket part 1 and the non-rotating parts of the pump, and guides the external slurry into the pump. In addition, together with the pump cover 4, the sealing box 13, the rear guard plate 5, the pump body A7, the middle guard plate 8, the pump body B11, the front guard plate 9, and the bracket 18 are connected together by bolt assemblies. Forms the fixed part of the working part of the pump.

[0027] The function of the conduit 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com