Intelligent inspection robot system of converter station valve hall based on combined track

A robot system and intelligent inspection technology, applied in two-dimensional position/channel control and other directions, can solve the problems such as the inability of mobile robots to complete the work requirements, the long inspection time of equipment in the valve hall, and the inability to meet the detection time, etc. Long-term continuous inspection work, rapid system construction, and realization of the effect of system construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below with reference to the accompanying drawings and embodiments.

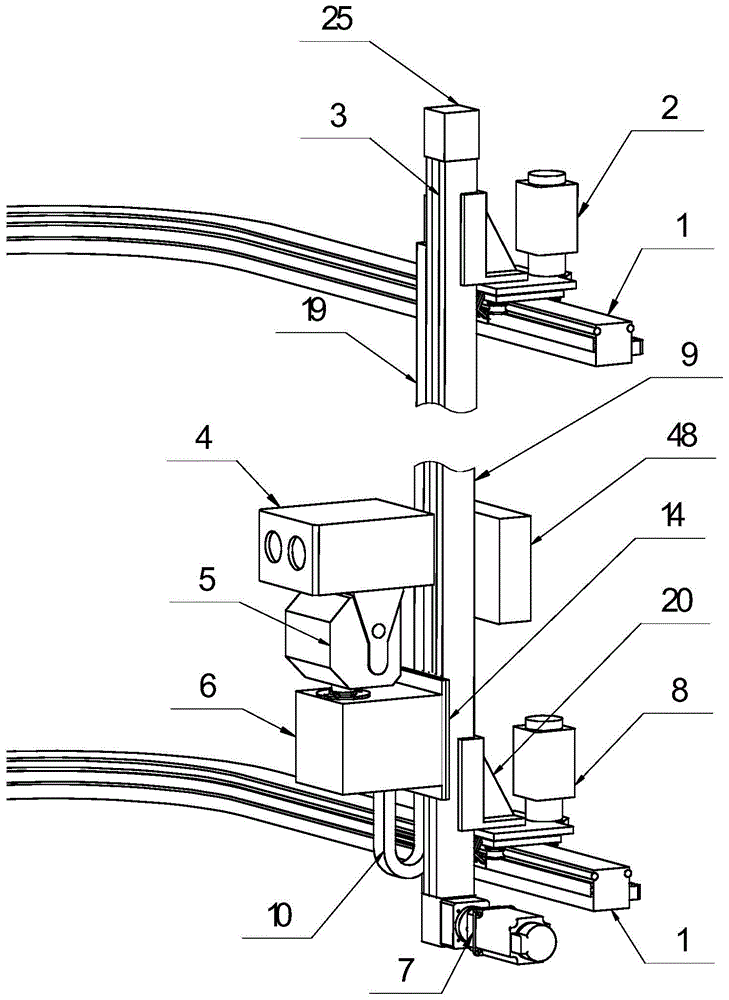

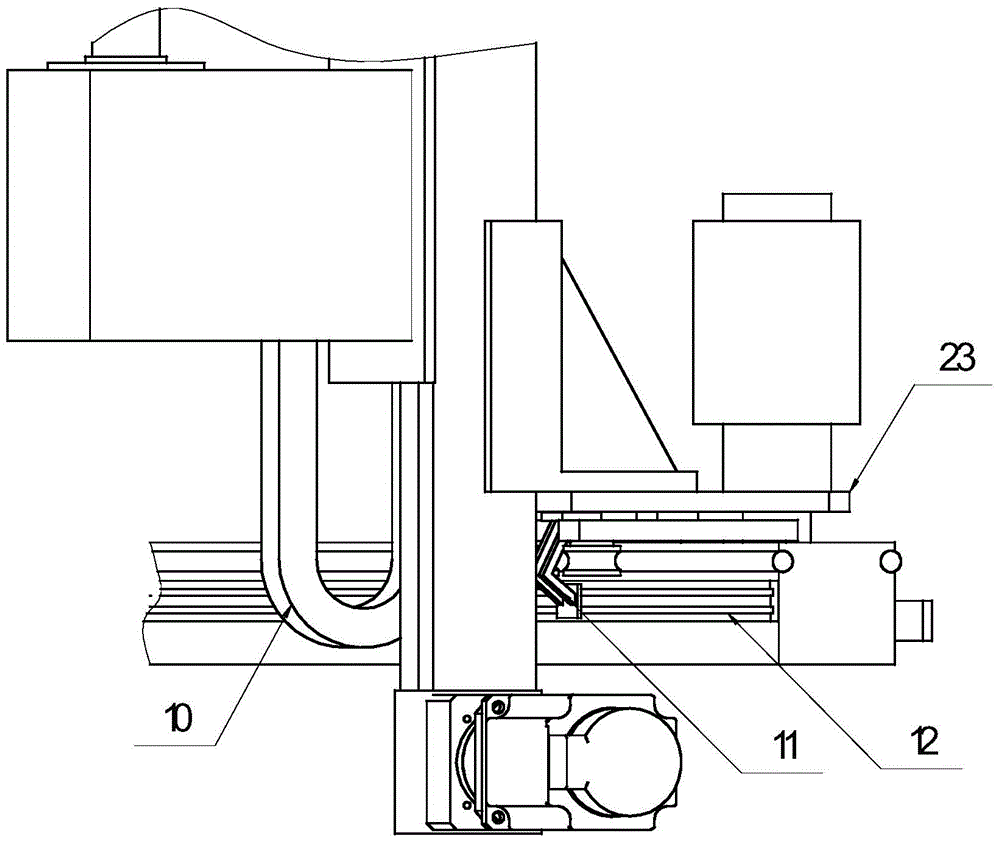

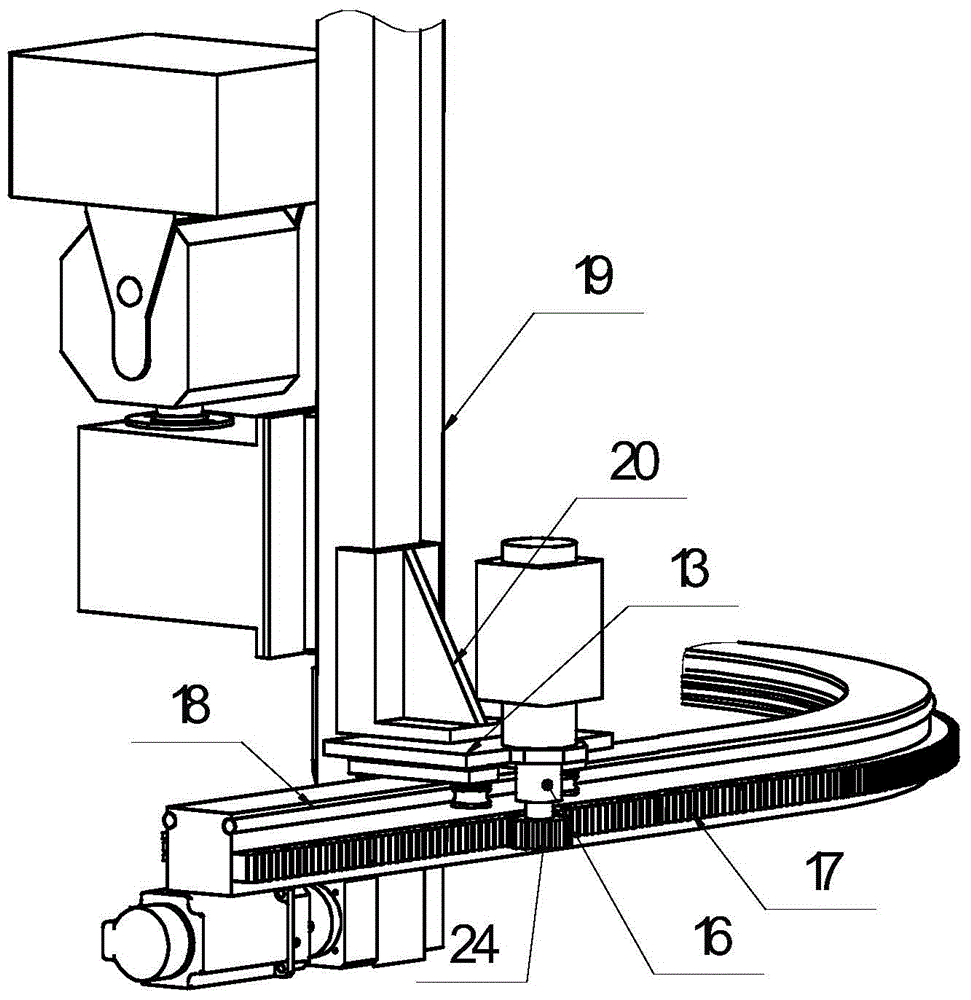

[0070] The combined track-based intelligent inspection robot system for the valve hall of the converter station includes a remote monitoring center 52 and a robot terminal system 49 . The remote monitoring center 52 and the robot terminal conduct wired communication through an optical fiber 53 . The robot terminal includes a detection device, a track drive positioning device, a communication control device, and the like. Among them, the communication control device is divided into three parts, which are the detection component and the pan-tilt control system (the pedestal control box), the motion control box 48 and the terminal communication box 51 respectively. The track drive positioning device is divided into horizontal track and vertical track. The vertical track is driven by synchronous belt, and the horizontal track is driven by rack and pinion. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com