Steel wire for high-strength spring having exceptional coiling performance and hydrogen embrittlement resistance, and method for manufacturing same

A manufacturing method and high-strength technology, applied in the direction of springs, manufacturing tools, furnace types, etc., can solve the problems of undisclosed high-strength, etc., and achieve the effects of excellent corrosion resistance, suppressed manufacturing costs, and excellent coilability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

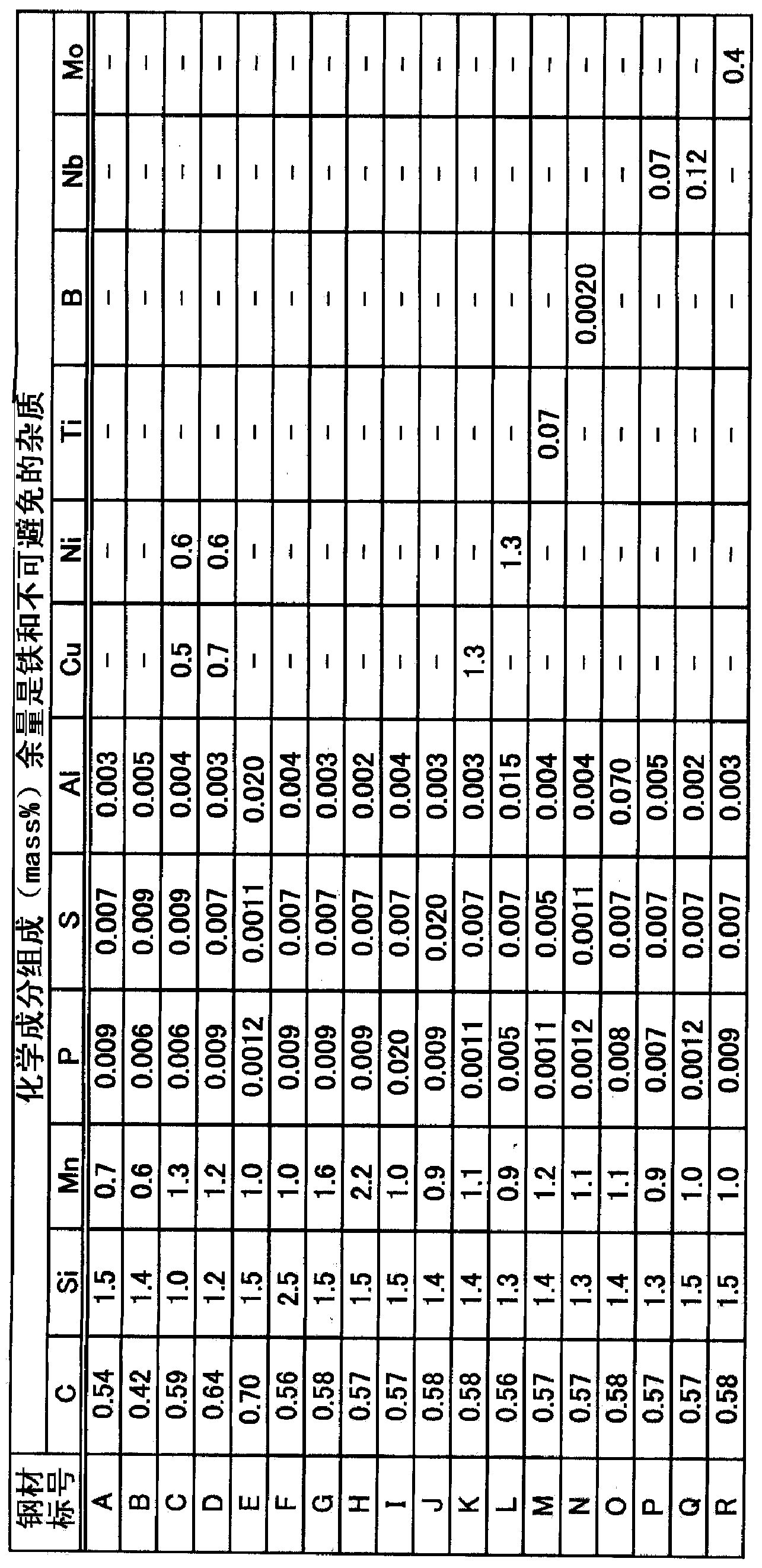

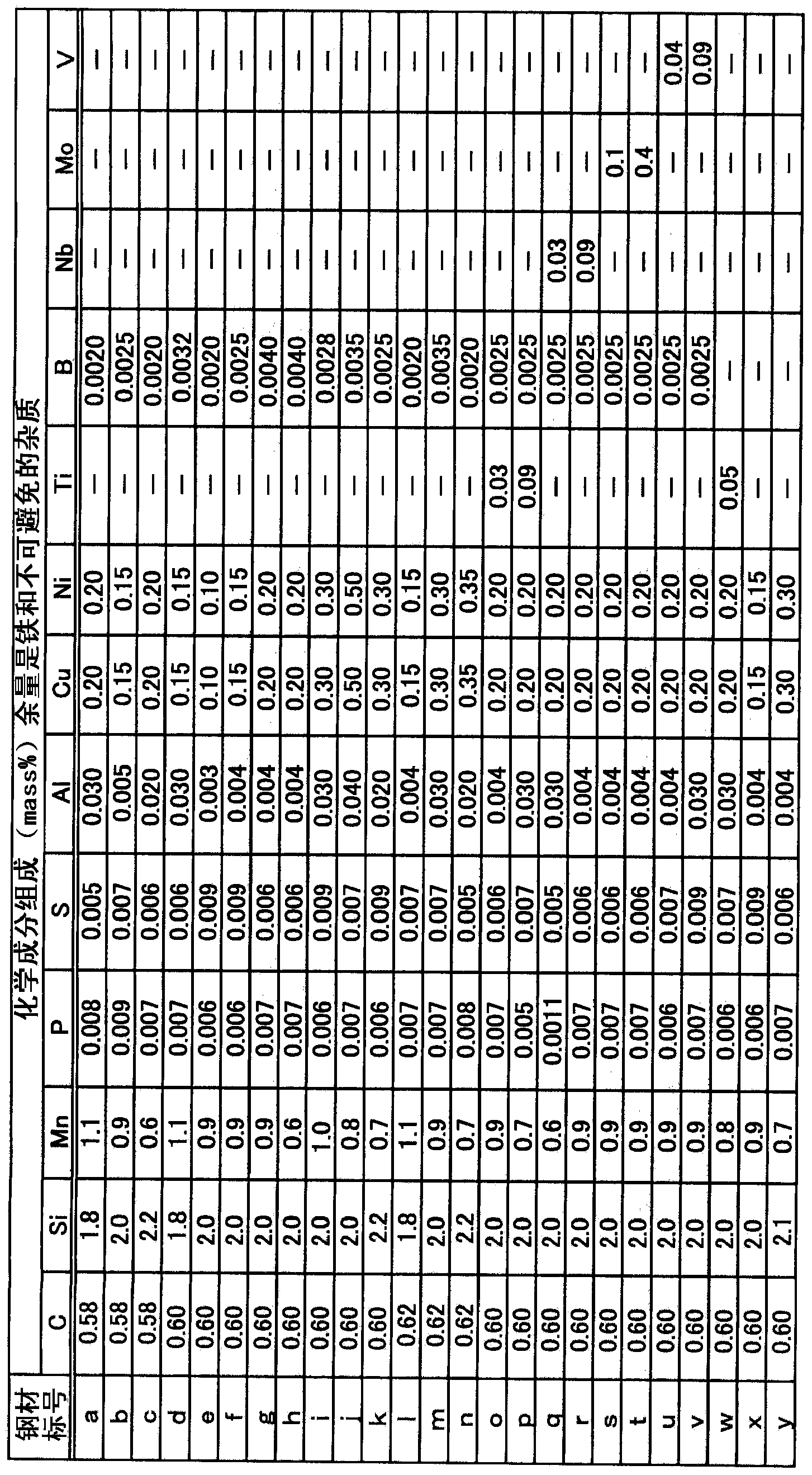

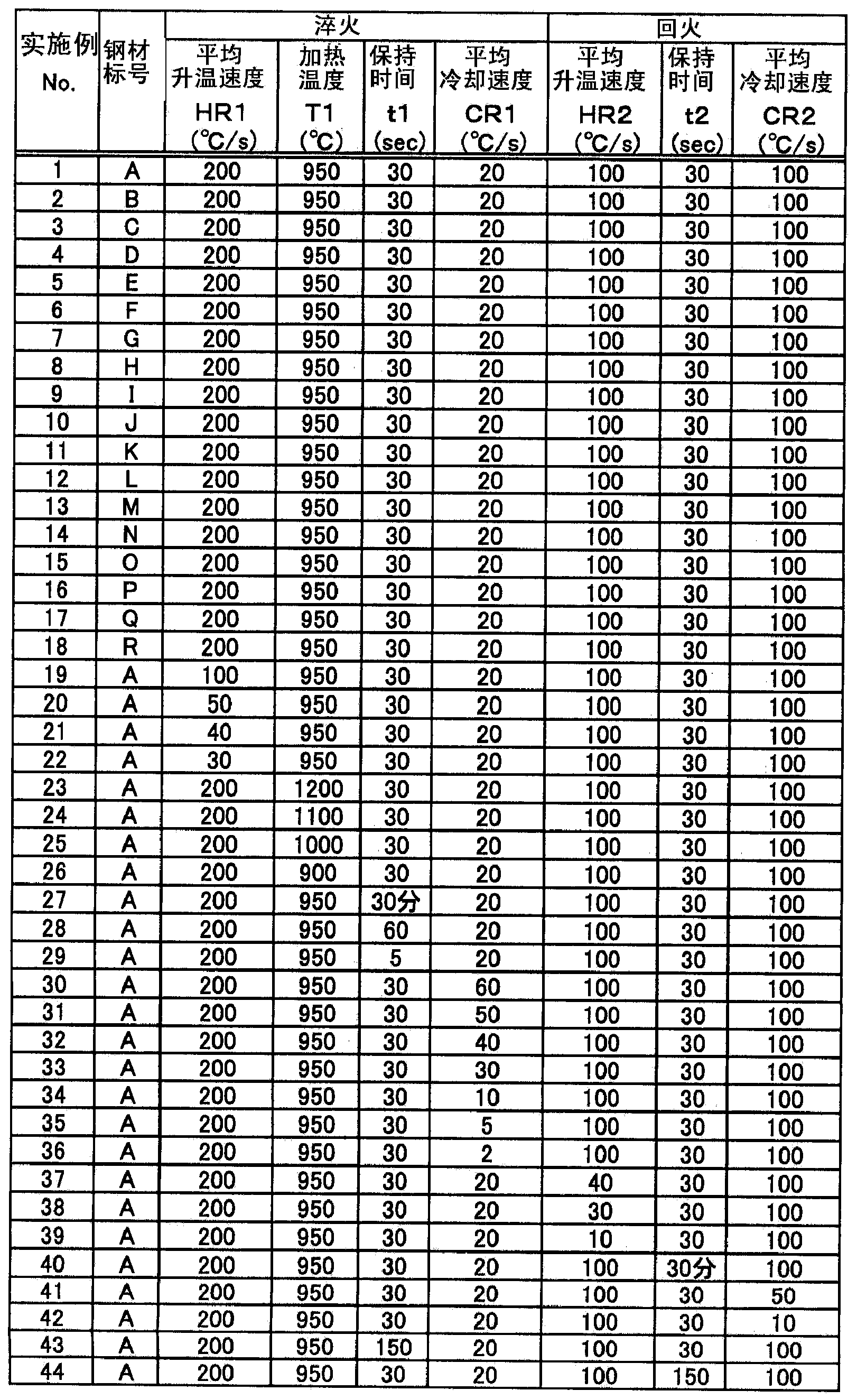

Method used

Image

Examples

Embodiment Construction

[0042] In order to solve the above-mentioned problems, the inventors of the present invention have made intensive studies to obtain a steel wire for springs that exhibits high strength without using alloy elements such as Cr and is excellent in coilability and hydrogen embrittlement resistance. As a result, it was found that even without using high-priced alloy elements, if the composition composed of basic components is controlled, and especially the quenching and tempering conditions in the manufacturing process are controlled, the structure described below is ensured without reducing the strength. The above-mentioned excellent characteristics can be achieved, and the present invention has been completed.

[0043] First, the reason for specifying the organization in the present invention will be described.

[0044] [organize]

[0045] [Amount of retained austenite (retained γ): 6 to 15 area%]

[0046] Austenite is soft and essentially a highly ductile phase. Therefore, by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com