A terminal covering system for domestic waste landfill

A technology of end-field coverage and domestic waste, applied in the direction of solid waste removal, etc., can solve the problems of not being able to meet multi-level and all-round needs, and achieve the effect of reducing greenhouse gas emissions, simple technical methods, and improving soil structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

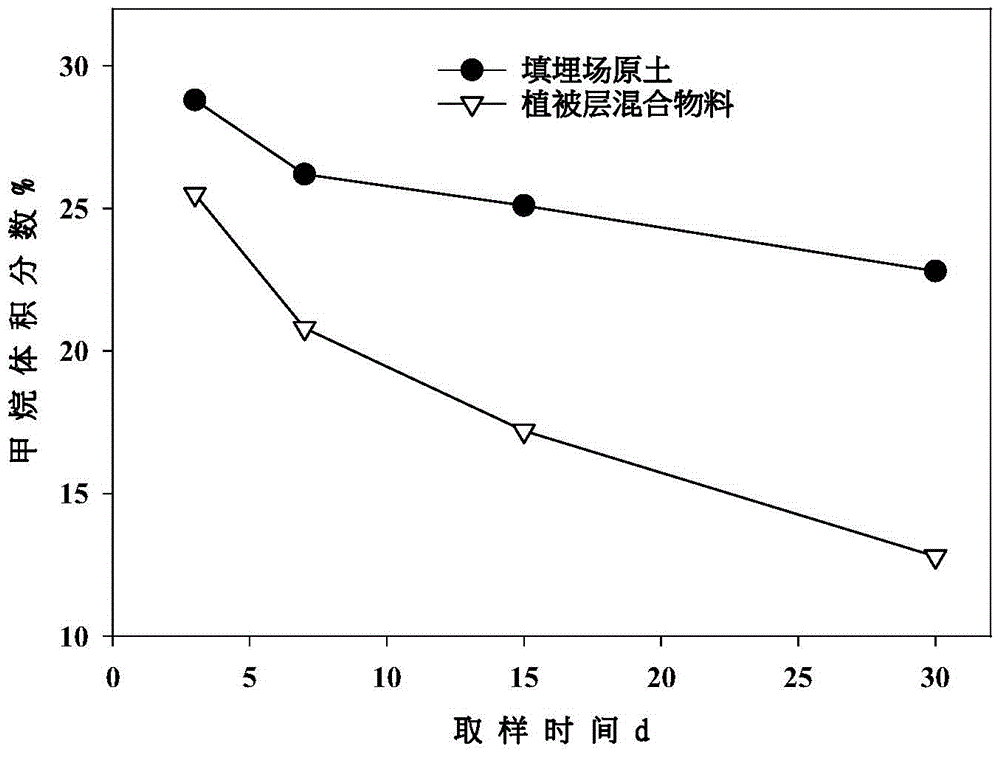

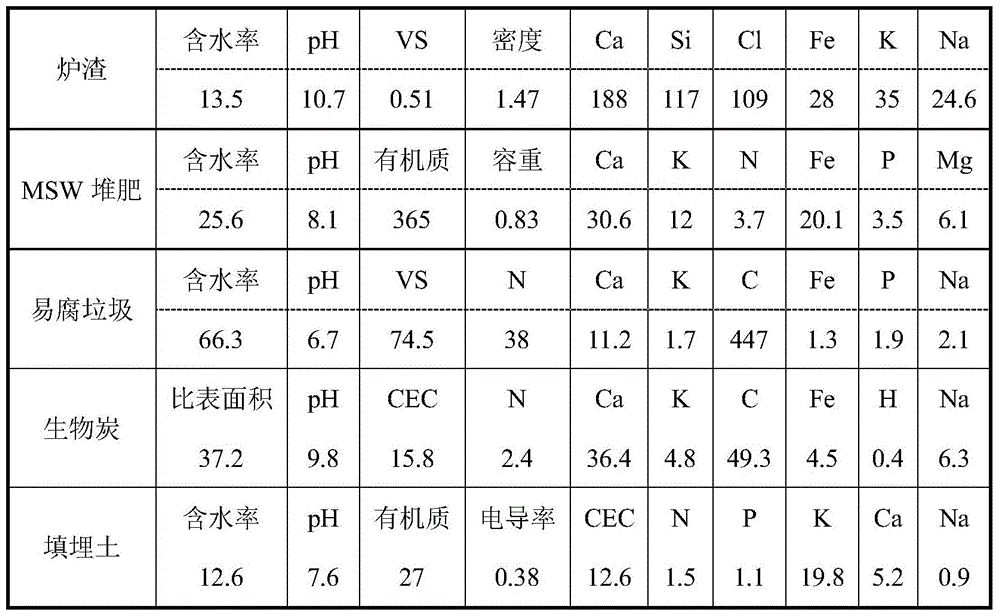

[0022] The utility model relates to an end-site covering system of a domestic garbage landfill, which includes, from the bottom to the top of the garbage dump, an exhaust layer, an anti-seepage layer, a drainage layer and a vegetation layer. Among them, the material of the exhaust layer is a mixture of waste incineration slag and gravel, the mixing ratio is 5:1, the particle size of the slag is 1-10mm, the particle size of the gravel is 2-40mm, and the thickness is 25cm; the anti-seepage layer The paved material is clay with a compacted thickness of 40cm; the paved material of the drainage layer is a mixture of waste incineration slag and gravel, the mixing ratio is 4:1, the particle size of the slag is between 10 and 40mm, and the particle size of the gravel is between 40-60mm, with a thickness of 35cm; the material for the vegetation layer is a mixture of landfill soil, waste composting products and biochar, with a mixing ratio of 100:5:1 and a thickness of 20cm. Among them,...

Embodiment 2

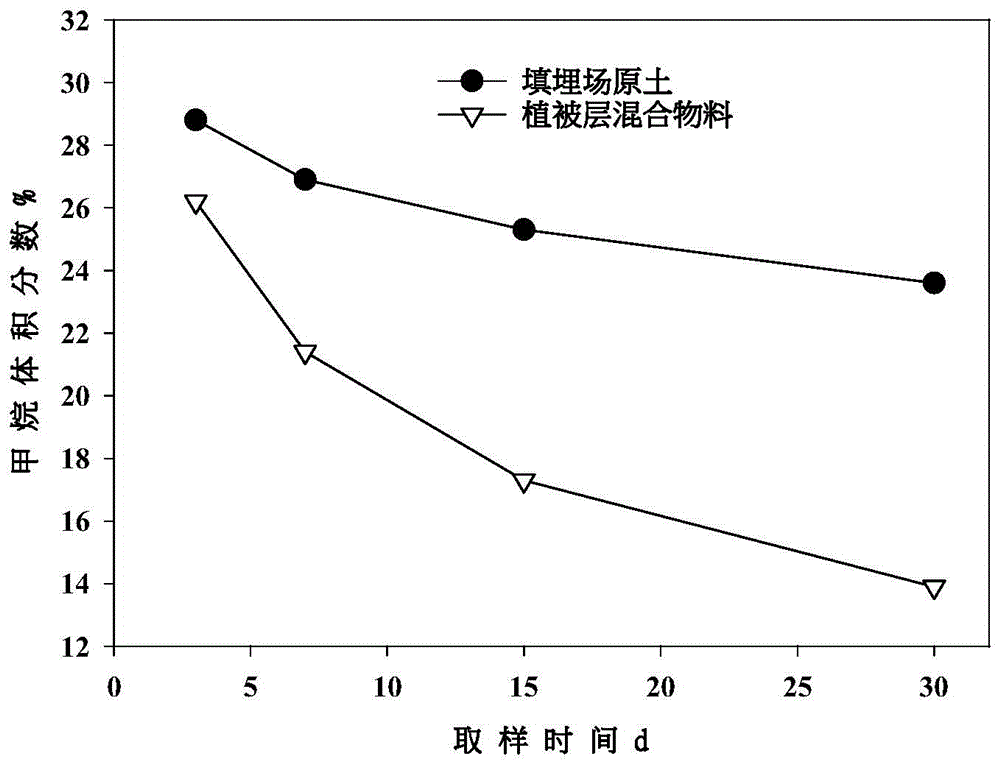

[0035] The utility model relates to an end-site covering system of a domestic garbage landfill, which includes, from the bottom to the top of the garbage dump, an exhaust layer, an anti-seepage layer, a drainage layer and a vegetation layer. Among them, the material of the exhaust layer is a mixture of garbage incineration slag and gravel, the mixing ratio is 4:1, the particle size of the slag is 1-10mm, the particle size of the gravel is 2-40mm, and the thickness is 30cm; the anti-seepage layer The paved material is clay with a compacted thickness of 30cm; the paved material for the drainage layer is a mixture of waste incineration slag and gravel, the mixing ratio is 2:1, the particle size of the slag is between 10 and 40mm, and the particle size of the gravel is between 40-60mm, with a thickness of 30cm; the material for the vegetation layer is a mixture of landfill soil, waste composting products and biochar, with a mixing ratio of 75:5:1 and a thickness of 30cm.

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com