Descaling guide device for hot continuous rolling machining applicable to wide strip steel

A wide-band steel and hot continuous rolling technology, which is applied in the field of descaling and guiding devices for hot continuous rolling processing, can solve the problems of high accident rate, small installation space of hydraulic cylinders, and knocking down, so as to avoid equipment and time costs, The effect of collision avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

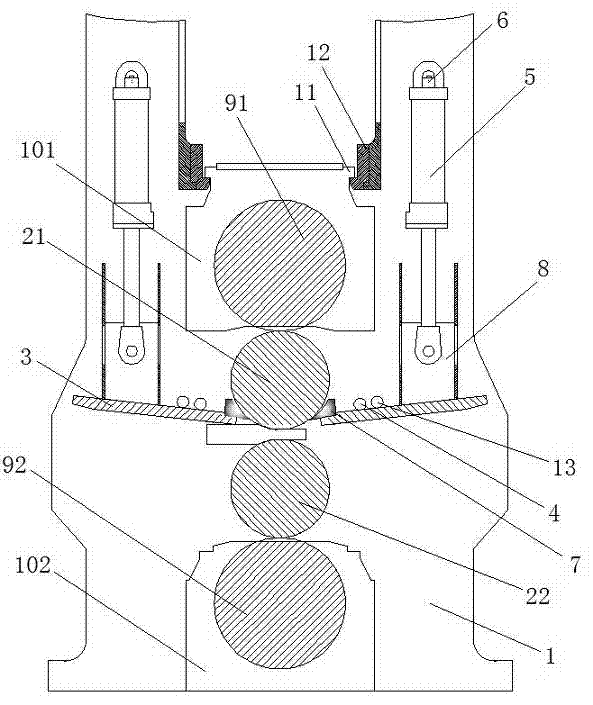

[0022] Such as figure 1 Shown is a descaling guide device suitable for hot continuous rolling of wide strip steel, which is installed in a rough rolling mill 1 for processing strip steel. The rough rolling mill 1 includes a pair of work rolls 2, which Comprising an upper work roll 21 and a lower work roll 22 opposite to each other; the descaling guide device suitable for wide strip steel processing includes, respectively, from the front end and the rear end of the work roll 2 to the two work rolls The descaling baffle 3 extending in the middle position, the descaling baffle 3 is provided with a descaling agent pipe 4, which is connected to the descaling agent tank arranged in the rough rolling mill 1; in the descaling baffle 3, it is The height of the end of one side of the work roll 2 is higher than the height of the lowest point of the upper work roll 21 , and the height is lower than the height of the side of the descaling baffle 3 away from the work roll 2 .

[0023] In t...

Embodiment 2

[0030] As an improvement of the present invention, the end of the descaling baffle 3 is provided with a friction end 7, which is made of wear-resistant material; The circumferences of the side end surfaces of the work rolls 21 are arc-shaped structures corresponding to each other, and the arc-shaped end surfaces of the friction end portion 7 and the upper work roll 21 are attached to each other. With the above design, the setting of the friction end makes the descaling end baffle and the work roll stick to each other, so that the descaling baffle can maintain a good relative position stability with the work roll during the working process, avoiding descaling The position of the baffle is shifted during the rotation of the work roll; at the same time, the wear resistance of the friction end can make the friction end and the upper support roll maintain a long working life under long-term contact.

[0031] The remaining features and advantages of this embodiment are the same as t...

Embodiment 3

[0033] As an improvement of the present invention, in the position-guiding hydraulic cylinder 5, the connecting portion between the hydraulic cylinder push rod and the descaling baffle 3 is provided with a connecting end body 8, which is fixedly connected to the upper end surface of the descaling baffle 3; Wherein, the area of the connecting end between the connecting end body 8 and the descaling baffle 3 is 1 / 3 of the upper surface area of the descaling baffle; With hinged connection.

[0034] With the above design, it can significantly improve the connection stability between the guide hydraulic cylinder and the descaling baffle by connecting the end body, so as to ensure that the guide hydraulic cylinder can stably support and drive the descaling baffle, and then The working stability of the descaling baffle is significantly improved, and the stress at the corresponding connection position of the descaling baffle and the guide hydraulic cylinder can be distributed to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com