A low-cost method for mechanically separating plastics from household waste

A technology for domestic waste and mechanical separation, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of high processing and separation cost, difficult separation, complicated operation, etc., to achieve a small footprint, low equipment cost, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

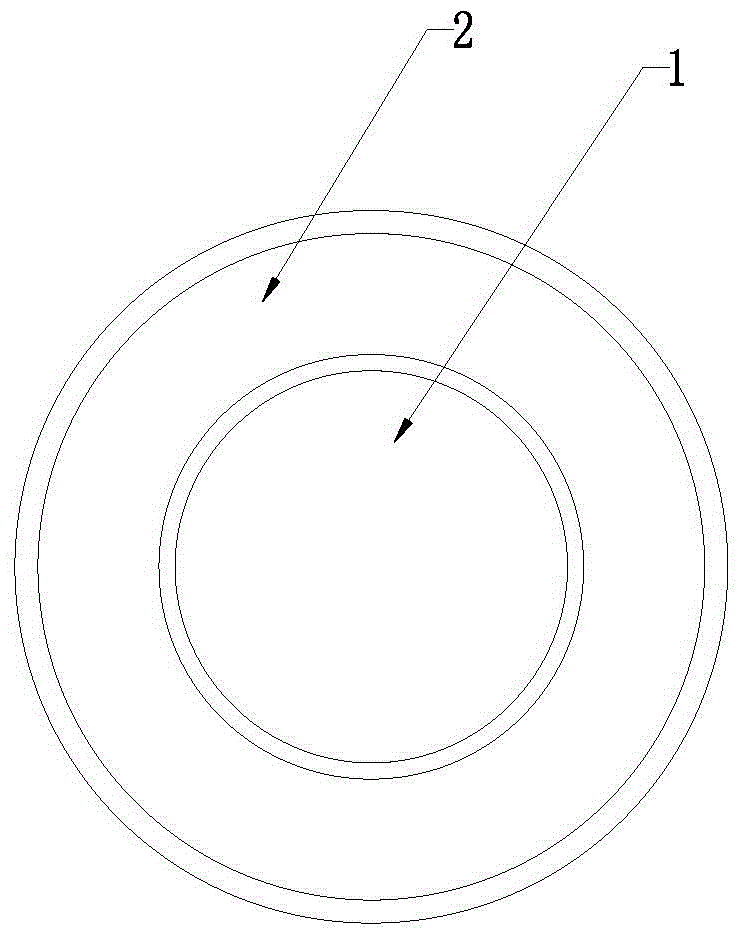

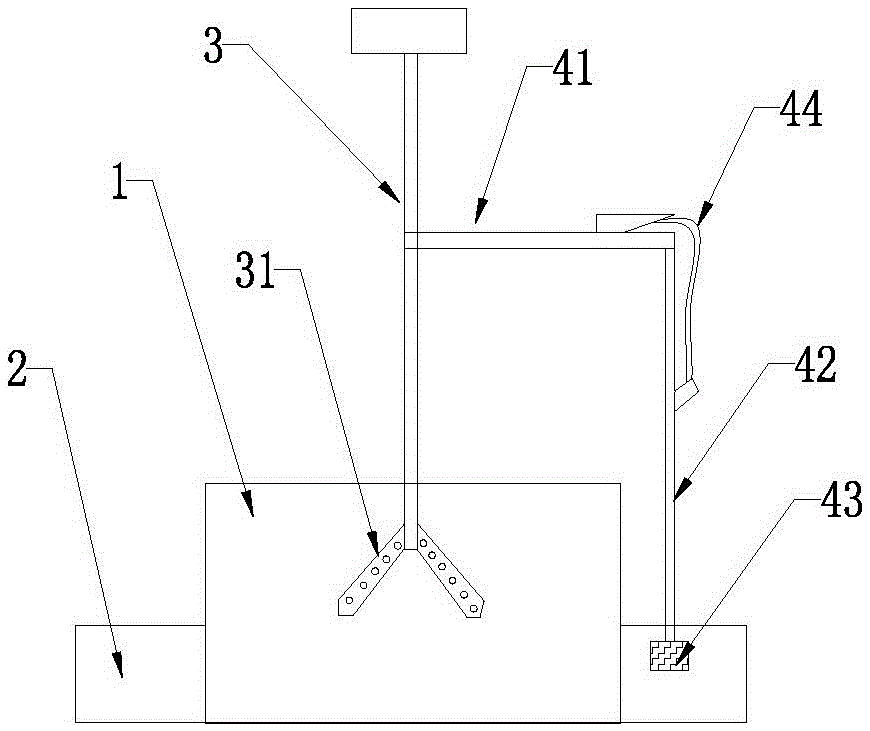

[0035] like Figures 1 to 2 As shown, a low-cost method for mechanically separating plastics from household garbage includes a garbage mixing tank, the garbage mixing tank includes a garbage treatment tank 1 and a garbage agitator 3, and a treatment liquid return tank 2 is provided below the garbage treatment tank 1 , the treatment liquid return tank 2 surrounds the surroundings of the garbage disposal tank 1, the area of the treatment liquid return tank 2 is 2-3 times that of the garbage treatment tank 1, and the treatment liquid return tank 2 is connected with the garbage treatment tank 1. There is a treatment liquid return pipe between the pools 1; the specific separation method is: put the garbage in the garbage treatment pool 1, fill the garbage treatment pool 1 with the treatment liquid containing biodegradable bacteria, and the garbage agitator 3 continuously Stir in the treatment tank 1, and the light plastics in the garbage float on the water surface, and the floati...

Embodiment 2

[0044] The difference between this embodiment and Embodiment 1 is that as an optimized method, with the continuous replenishment of the treatment liquid and the agitation of the agitator, the plastic waste with a lighter specific gravity will be flushed into the treatment liquid return tank 2, and the plastic waste will Get separate separation for easy recycling.

[0045] Further, the setting of the stirring paddle 31 is inclined, forming 10-30° with the horizontal plane, then when stirring, the water flow forms a small vortex, which is conducive to pushing up the plastic waste, and the separation effect is good.

Embodiment 3

[0047] like Figures 1 to 2 As shown, a low-cost method for mechanically separating plastics from household garbage includes a garbage mixing tank, the garbage mixing tank includes a garbage treatment tank 1 and a garbage agitator 3, and a treatment liquid return tank 2 is provided below the garbage treatment tank 1 , the treatment liquid return tank 2 surrounds the surroundings of the garbage disposal tank 1, the area of the treatment liquid return tank 2 is 2-3 times that of the garbage treatment tank 1, and the treatment liquid return tank 2 is connected with the garbage treatment tank 1. There is a treatment liquid return pipe between the pools 1; the specific separation method is: put the garbage in the garbage treatment pool 1, fill the garbage treatment pool 1 with the treatment liquid containing biodegradable bacteria, and the garbage agitator 3 continuously Stir in the treatment tank 1, and the light plastics in the garbage float on the water surface, and the floati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com