Red luminescent fluorescent powder and preparation method thereof

A technology for red light-emitting and phosphor powder, applied in the field of phosphor materials, can solve the problems of high cost, inability to be widely used, difficult preparation and the like of red light-emitting phosphor powder, and achieve the effects of low price, easy storage conditions, and easy preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Ca 0.95 AlGdSiN 4 : Preparation of 0.05Eu phosphor.

[0030] Using elemental Ca, Al, Gd, Si, and Eu as raw materials, and by weighing the ratio of the amount of the above raw materials to satisfy Ca:Al:Gd, Si:Eu=0.95:1:1:1:0.05, the above The weighed raw materials are put into an electric arc melting furnace for instant electric arc high-temperature melting to form an alloy body, and the obtained alloy body is crushed and ball-milled to obtain an alloy powder, which is put into a zirconia crucible and placed in a N 2 / H 2 Mixed atmosphere (N 2 with H 2 The volume ratio can be 75:25-95:5, the same below) and sinter at 1800°C for 5 hours, take out the sintered sample after cooling, and wash the sintered sample with deionized water until the pH value of the washing liquid is neutral. After drying, Ca 0.95 AlGdSiN 4 : 0.05Eu phosphor.

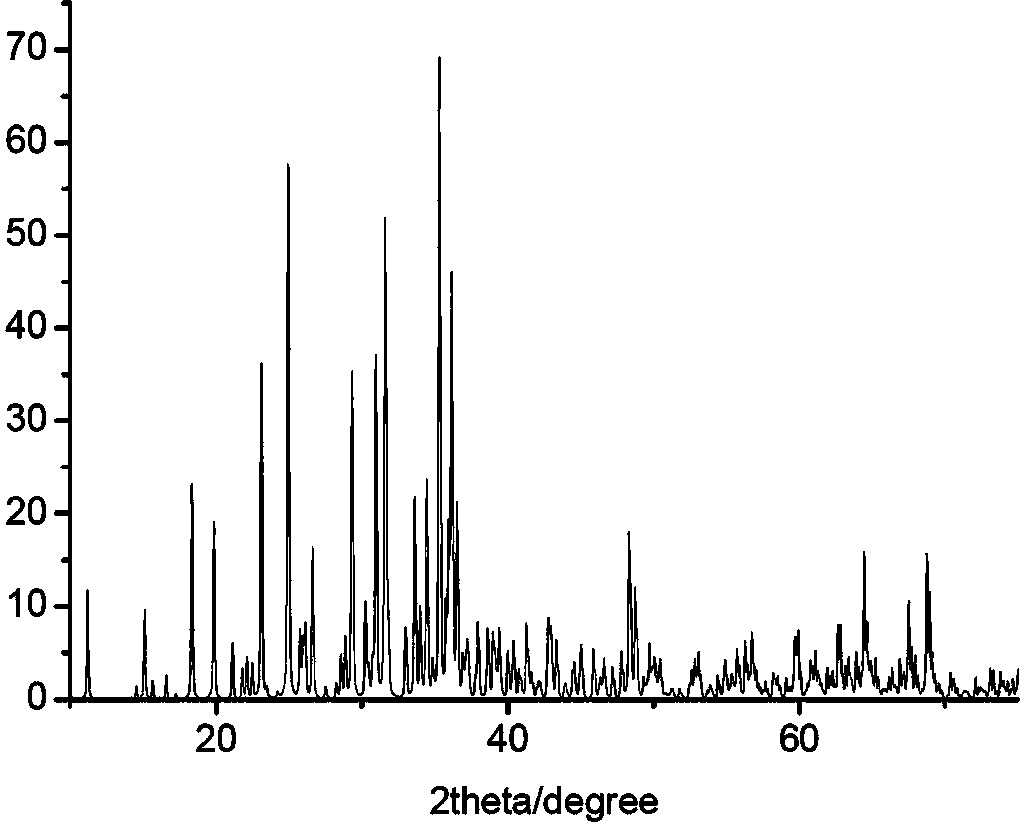

[0031] For the prepared Ca 0.95 AlGdSiN 4 : 0.05Eu fluorescent powder for X-ray diffraction test, the obtained X-ray d...

Embodiment 2

[0034] Example 2: Sr 0.1 Ca 0.8 Mg 0.09 Gd 0.05 Al 1.95 SiN 4 : Preparation of 0.01Eu phosphor.

[0035] Use elemental Sr, Ca, Mg, Gd, Al, Si, and Eu as raw materials, and make the ratio of the amount of the above raw materials meet Sr:Ca:Mg:Gd:Al:Si:Eu=0.1:0.8 by weighing: 0.09: 0.05: 1.95: 1: 0.01, put the raw materials weighed above into the arc melting furnace for instantaneous arc high-temperature melting to form alloy body, crush the obtained alloy body and obtain alloy powder after ball milling, put the alloy powder into oxidation Zirconium crucible, in N 2 / H 2 Sinter at 1600°C for 8 hours in a mixed atmosphere, take out the sintered sample after cooling, wash the sintered sample with deionized water until the pH value of the washing solution is neutral, and then dry to obtain Sr 0.1 Ca 0.8 Mg 0.09 Gd 0.05 Al 1.95 SiN 4 : 0.01Eu phosphor.

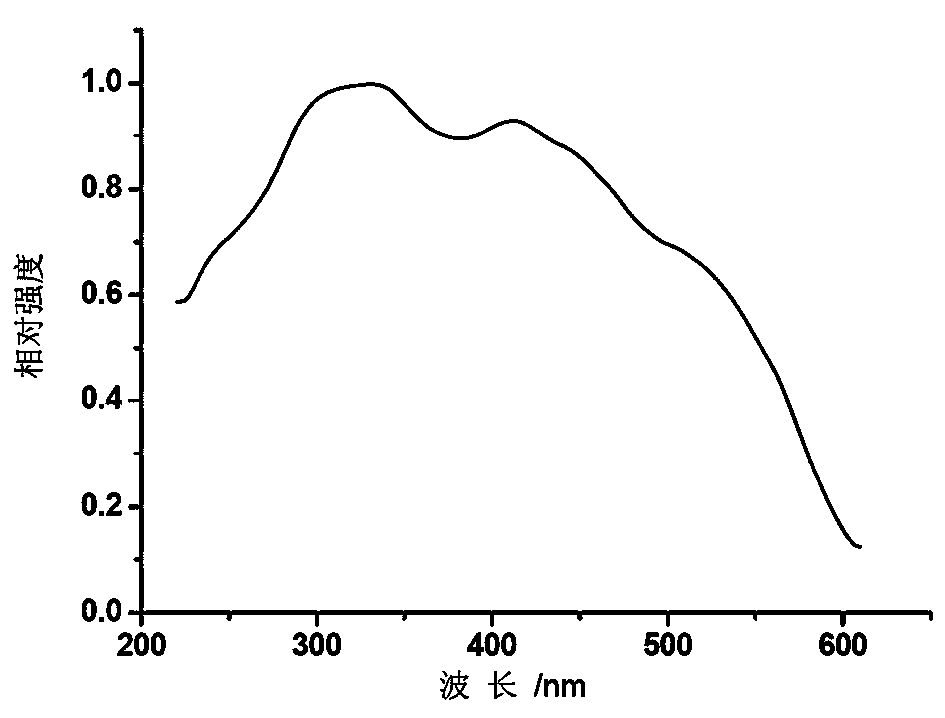

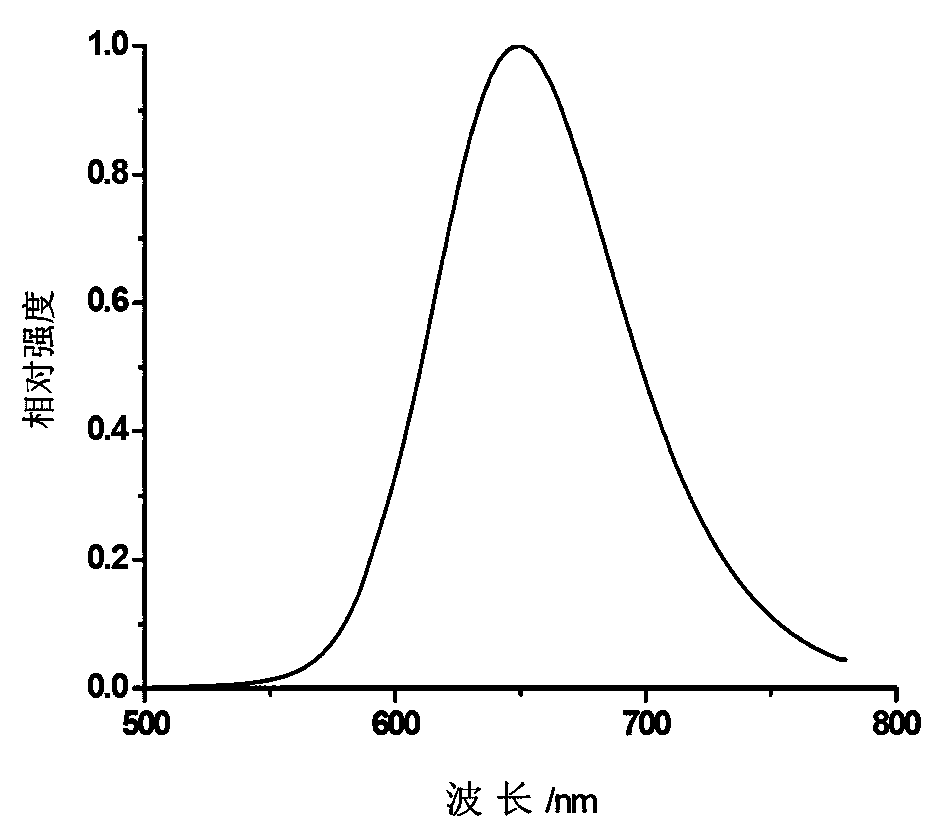

[0036] For the prepared Sr 0.1 Ca 0.8 Mg 0.09 Gd 0.05 Al 1.95 SiN 4 : 0.01Eu phosphor for excitation spectrum ...

Embodiment 3

[0038] Example 3: Ca 0.7 Ba 0.1 Ga 0.05 Al 1.95 SiN 4 : Preparation of 0.2Eu phosphor.

[0039] Elemental Ca, Ba, Ga, Al, Si, and Eu are used as raw materials, and the ratio of the amount of the above raw materials is satisfied by weighing Ca:Ba:Ga:Al:Si:Eu =0.7:0.1:0.05:1.95: 1:0.2, put the raw materials weighed above into an electric arc melting furnace for instantaneous arc high-temperature melting to form an alloy body, crush and ball-mill the obtained alloy body to obtain alloy powder, put the alloy powder into a zirconia crucible, and 2 / H 2 Sinter at 2100°C for 3 hours in a mixed atmosphere, take out the sintered sample after cooling, wash the sintered sample with deionized water until the pH value of the washing solution is neutral, and then dry to obtain Ca 0.7 Ba 0.1 Ga 0.05 Al 1.95 SiN 4 : 0.2Eu phosphor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission peak | aaaaa | aaaaa |

| Emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com