High-strength deformable zinc-based alloy material

An alloy material and high-strength technology, applied in the field of high-strength deformed zinc-based alloy materials, can solve the problems of poor plasticity and low strength, and achieve good machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

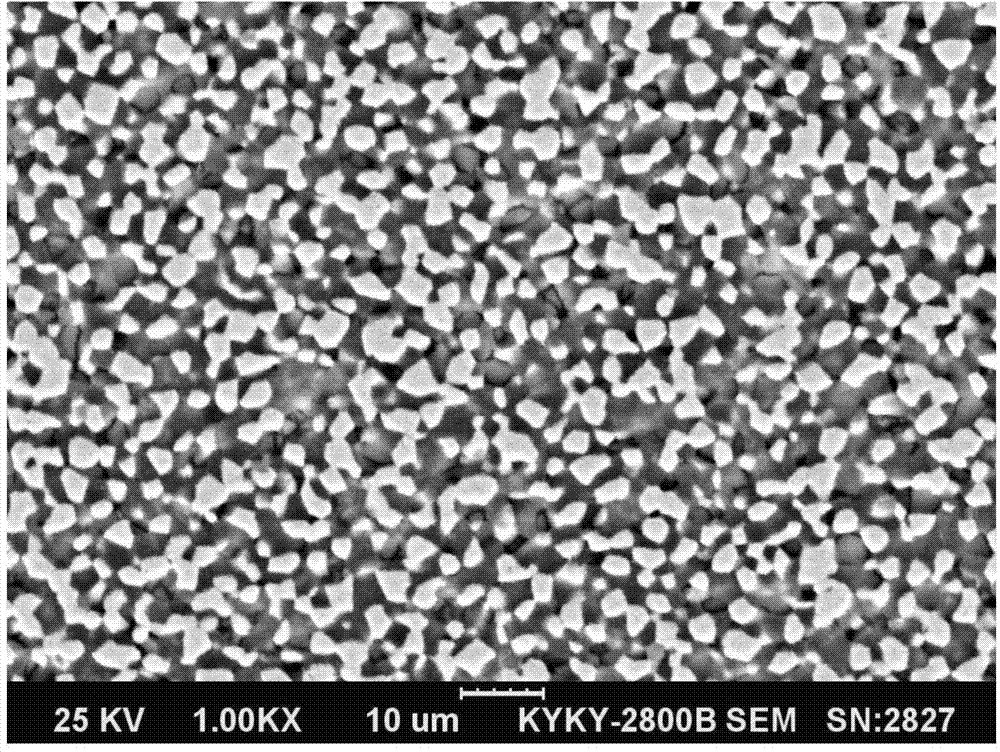

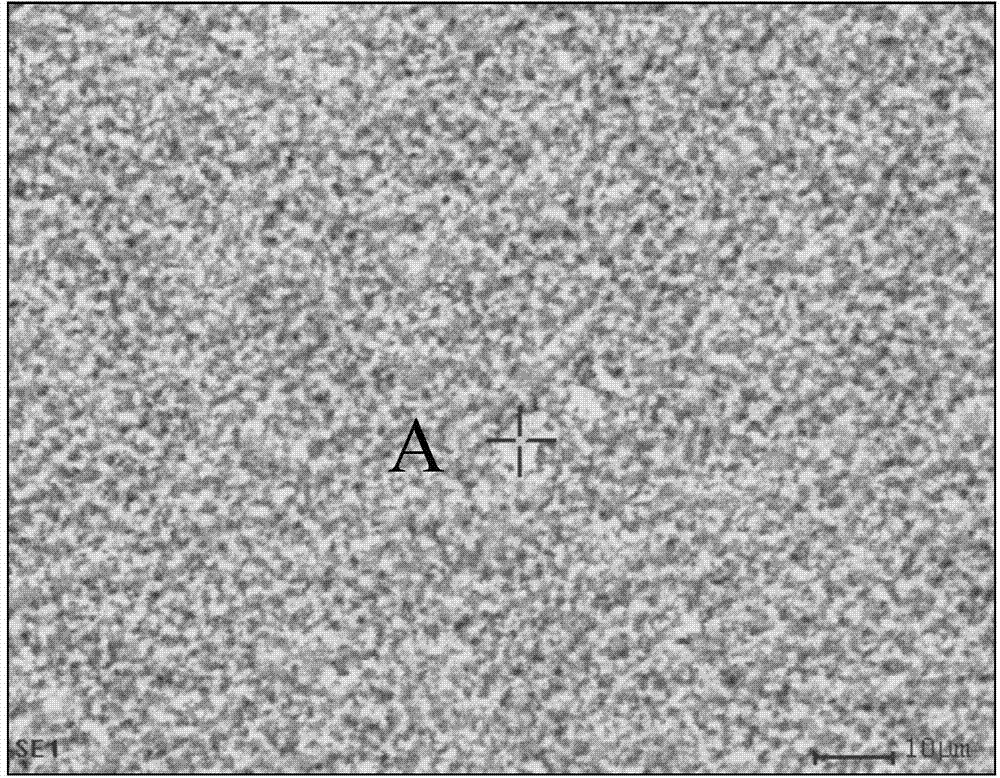

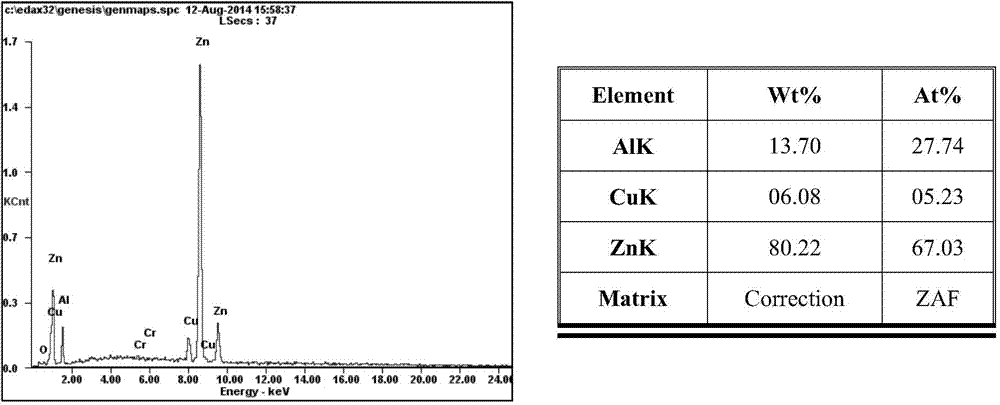

[0035] Select 25 example alloys and 2 comparative alloys, use induction melting or gas heating to melt the master alloy, and then use continuous casting or die casting to make a billet with a diameter of 170mm, heat it at a temperature of 180-380°C It is extruded into a bar with a diameter of 13mm, and finally processed into a finished product with a diameter of Ф12mm through cold drawing.

[0036] The tensile test at room temperature is carried out on an electronic universal mechanical performance testing machine in accordance with "GB / T228.1-2010 Metal Material Tensile Test Part 1: Room Temperature Test Method". The stretching speed is 5mm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com