Aluminum alloy anode oxidation device

Anodizing, aluminum alloy technology, applied in anodizing, cells, electrolysis process, etc., can solve problems affecting equipment work, etc., to reduce moisture and rust, ensure suction efficiency, and prevent falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

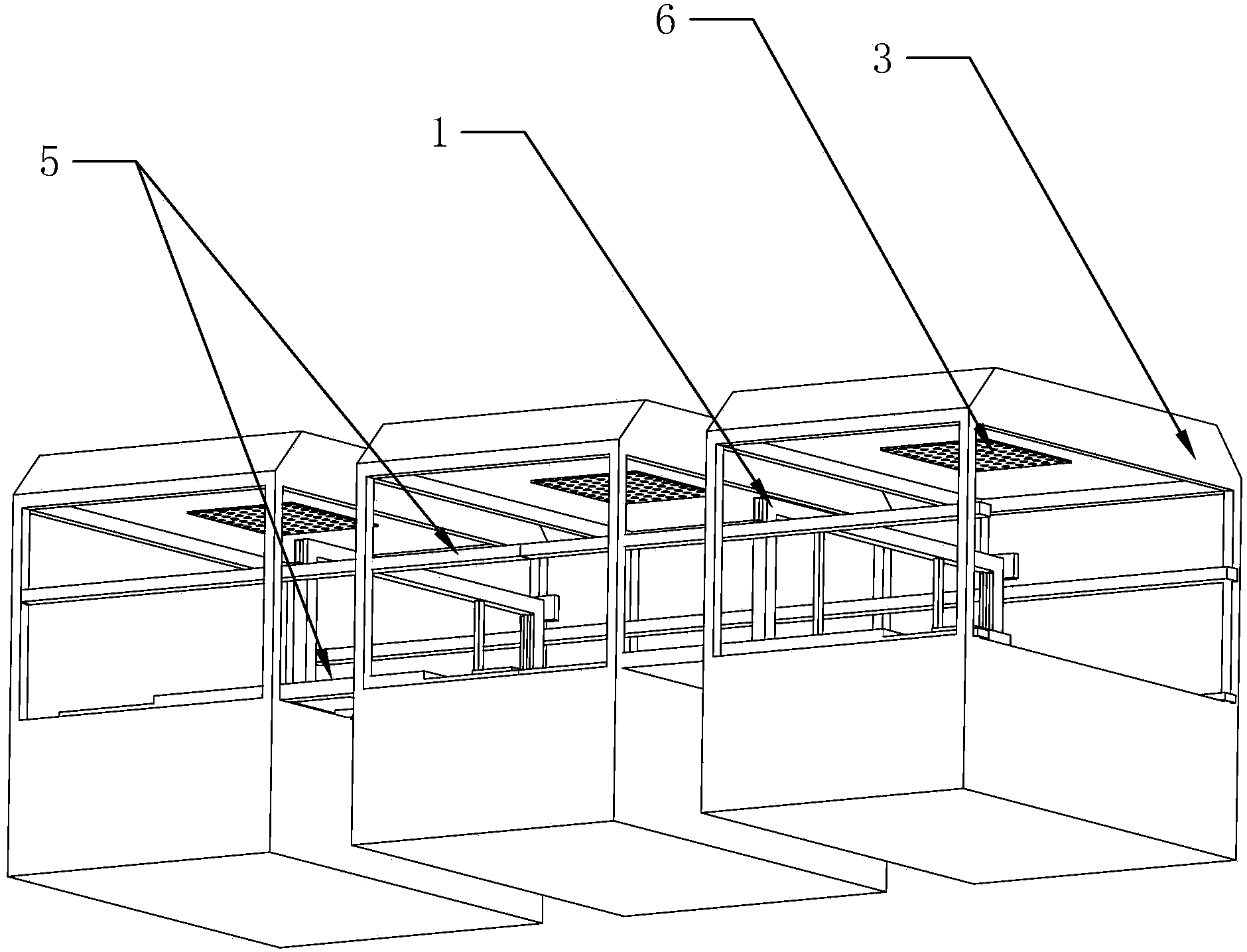

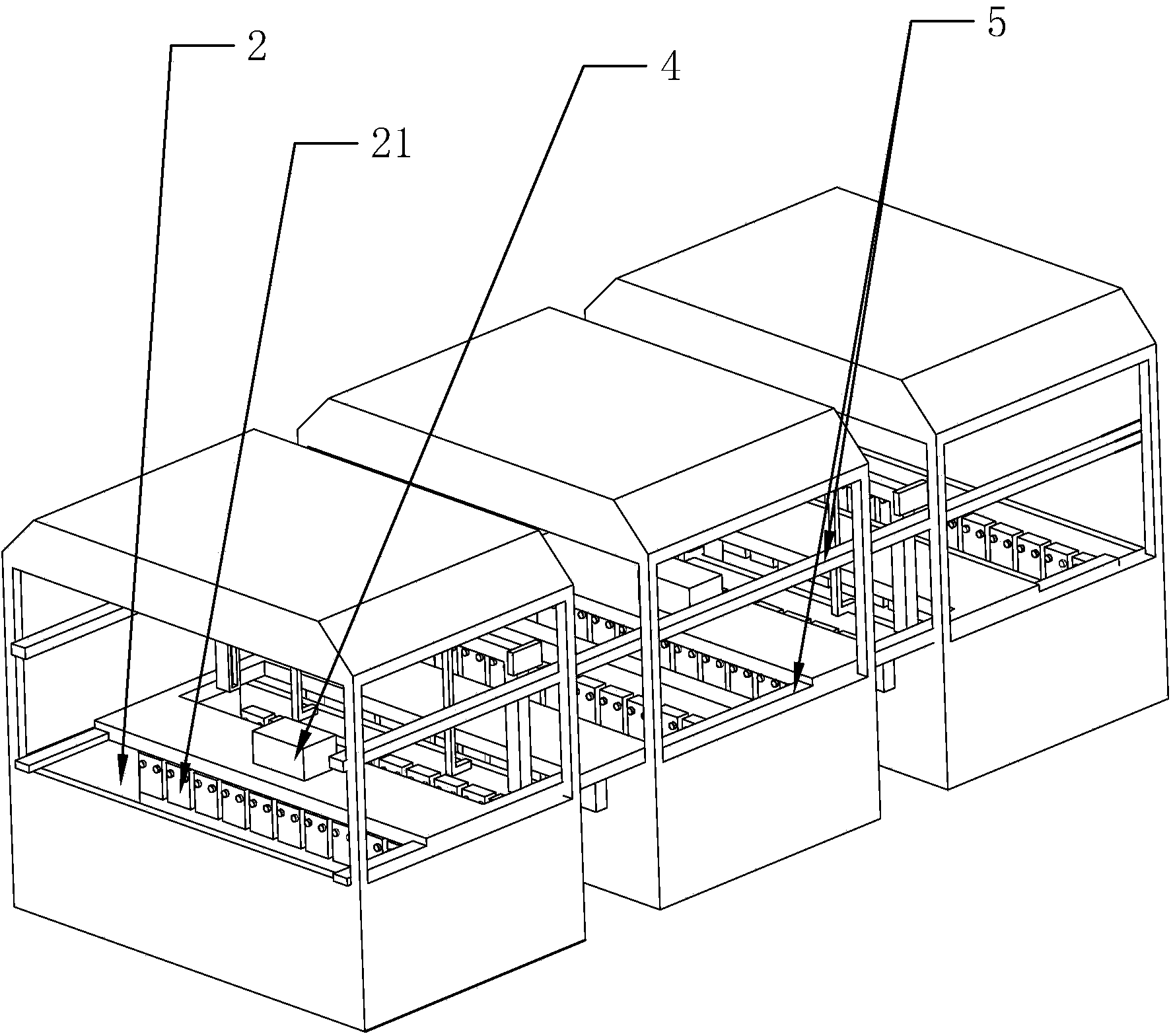

[0020] Reference attached Figure 1 to Figure 6 The embodiments of the exhaust hood of the present invention are further described.

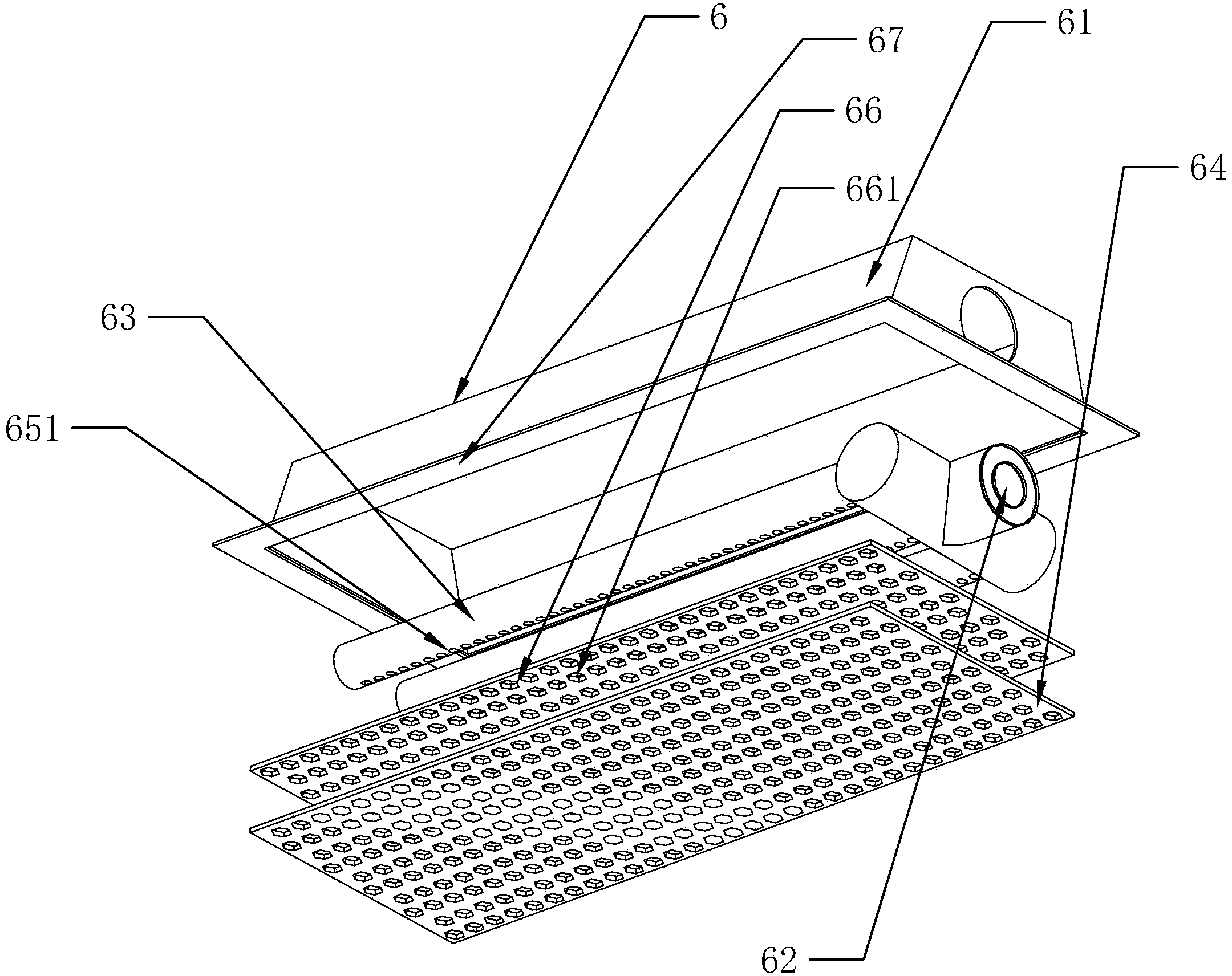

[0021] An aluminum alloy anodizing equipment, such as Figure 1 to Figure 3 As shown, it includes support 3, electrolyzer 2, crane 1 and PLC control cabinet 4. On support 3, slide rail 5 is laid, and PLC control cabinet 4 makes the crane 1 slide on slide rail 5, in electrolyzer 2 At least three or more cathode conductive devices 21 are also fixed on the inner wall, which can be three, four, or ten. In this embodiment, there are preferably ten. The cathode conductive devices 21 are lead plates 21, and the lead plates 21 It has almost no corrosion in sulfuric acid and has a long service life. The lead plate 21 is the prior art, and will not be repeated here. In the vertical direction of the electrolytic cell 2, an exhaust hood 6 is welded through the bracket 3, and the exhaust hood 6 It includes a cover body 61. A suction cavity 62 is opened in the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com