Walking-beam-free type intelligent oil pumping unit

A beamless pumping unit technology, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problem of not being able to adapt to the balance state of the pumping unit, destroying the balance state of the pumping unit, requiring maintenance and deceleration problems such as equipment, to achieve the effect of improving workover operation speed, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

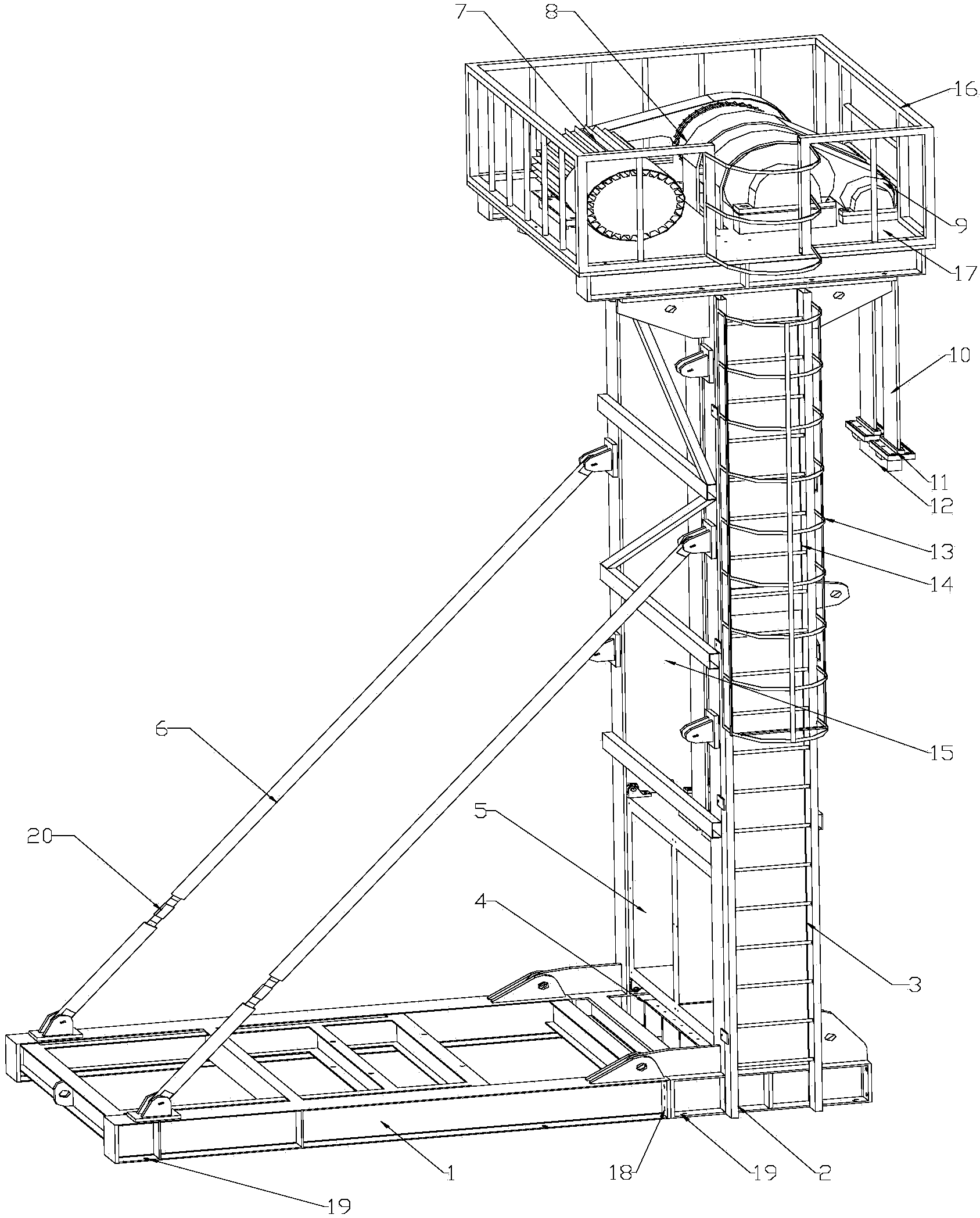

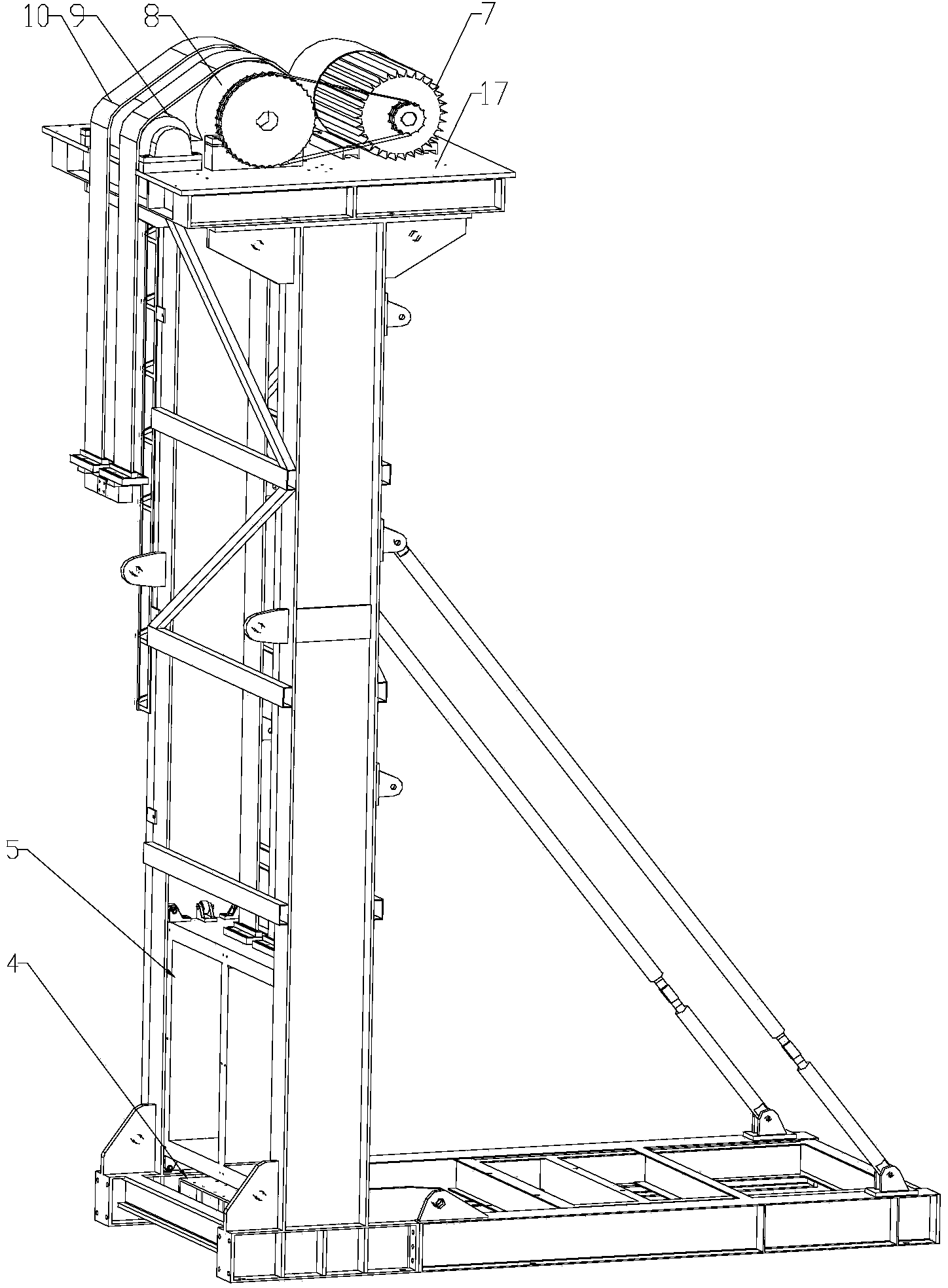

[0011] Depend on figure 1 combine figure 2 As shown, the beamless intelligent pumping unit includes a fixed base 1 and a movable base 2, the fixed base 1 and the movable base 2 are connected through a pin-type joint connection and fastening bolts 18, and the upper part of the movable base 2 is fixedly connected to the frame 3 , the frame 3 is a steel bracket structure, the upper end of the frame 3 is hinged with the fixed base 1 through a pull rod 6, the upper end of the frame 3 is provided with a platform 17, and a permanent magnet motor 7 is installed on the platform 17, and the permanent magnet motor 7 and the driving roller 8 Connected by chain transmission, the drive roller 8 is equipped with a guide roller 9 parallel to the axis of the drive roller 8 near the edge of the platform 17, and the drive roller 8 is provided with a long hole near the platform 17 of the per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com