Microcrystalline mica heating plate device and manufacturing method thereof

A technology of microcrystalline mica and heating plate, applied in the direction of electric heating devices, heating methods, lighting and heating equipment, etc., can solve the problems of easy harm to the human body, large space occupation, large water loss, etc., and achieve fast heating speed, heat Uniform field, enhanced resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

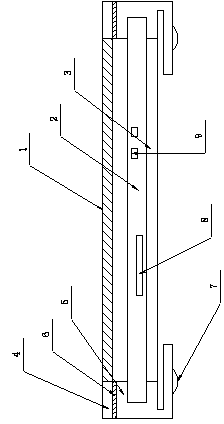

[0011] see figure 1 , this specific embodiment adopts the following technical solutions: it includes a push-pull decorative painting layer 1, a microcrystalline mica heating plate layer 2, an aluminum foil insulation film layer 3, a push-pull aluminum alloy frame 4, an aluminum alloy base frame 5, and a three-section steel ball slide rail 6 , aluminum alloy base frame heel 7, temperature control switch 8, high temperature resistant male-female connection power cord 9, the both sides of described push-pull type decorative painting layer 1 are provided with push-pull aluminum alloy frame 4, push-pull type decorative painting layer 1 both sides The three-section steel ball slide rail 6 is arranged on the aluminum alloy base frame 5, and the microcrystalline mica heating plate layer 2 is arranged between the two aluminum alloy base frames 5, and the lower end of the microcrystalline mica heating plate layer 2 is provided with an aluminum foil thermal insulation film layer 3, The b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com