Turbine sequence valve load abrupt fault diagnosis method based on high control valve switch test

A load mutation and fault diagnosis technology, which is applied in engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as unit load sudden drop, software and hardware failures, etc., to ensure safety and large-scale practical application value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

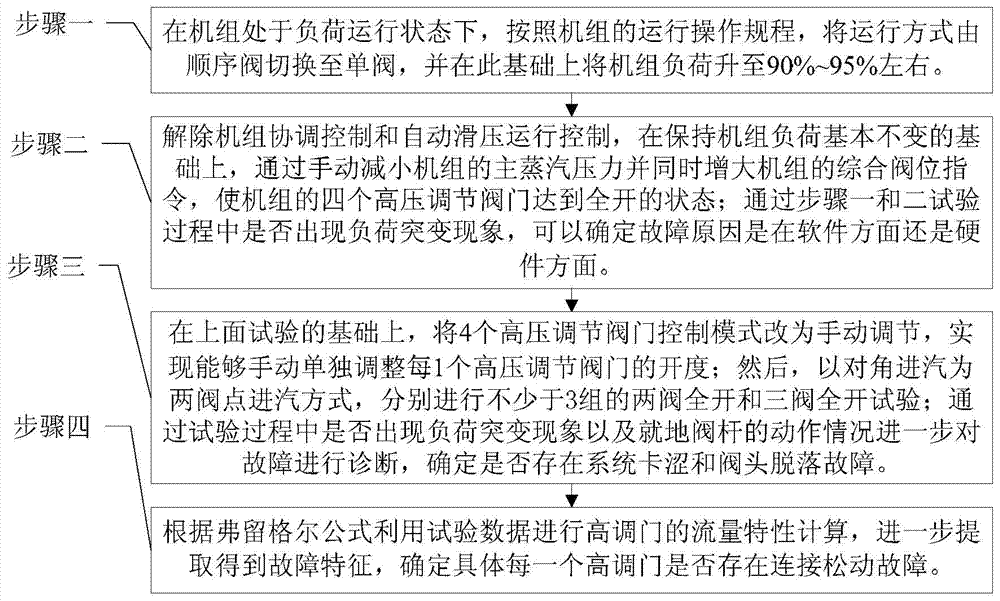

[0034] Specific implementation mode one: as figure 1 As shown, it is the specific process of this embodiment: the fault diagnosis method for the sudden change of load of the steam turbine sequence valve based on the high-profile door switch test is realized in the following steps:

[0035] Step 1: When the unit is in load operation state, switch the operation mode from sequence valve to single valve, and increase the unit load to 90% to 95%;

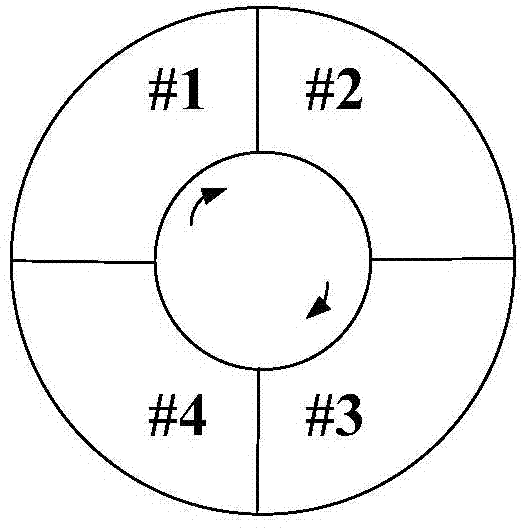

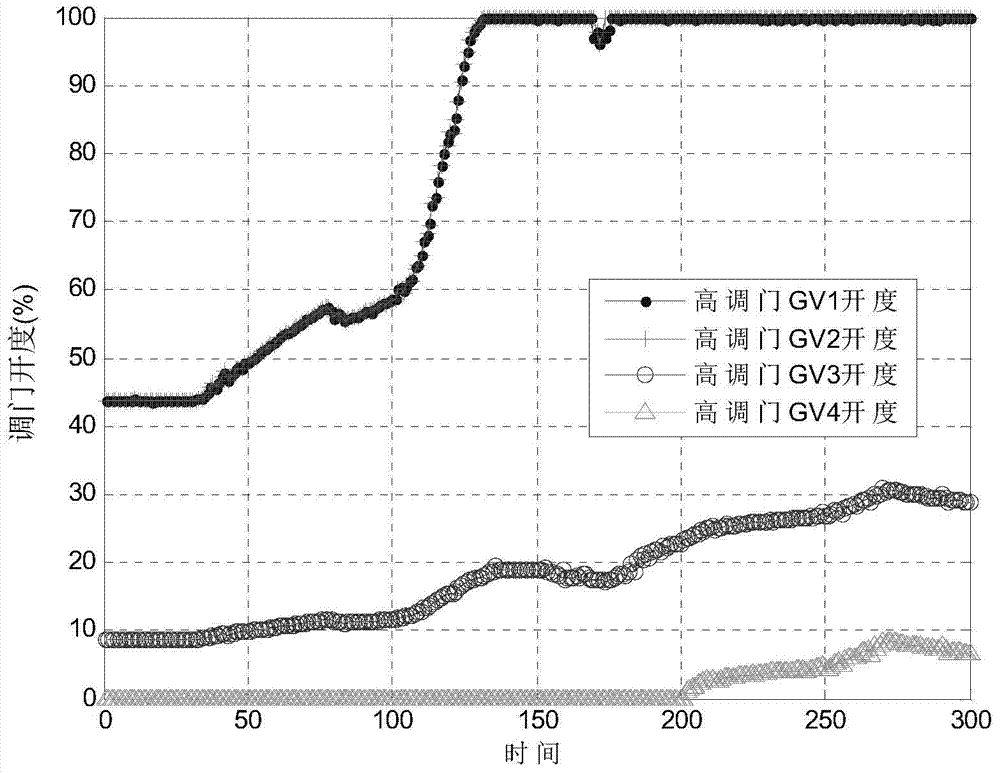

[0036] Step 2: Release the unit coordination control and automatic sliding pressure operation control. On the basis of keeping the unit load basically unchanged, manually reduce the main steam pressure of the unit and increase the comprehensive valve position command of the unit at the same time, so that the four units of the unit When the high-pressure regulating valve reaches the fully open state, when the high-pressure regulating valve of the unit changes in a large range, the load change of the unit is within the range required by th...

specific Embodiment approach 2

[0049] Embodiment 2: This embodiment differs from Embodiment 1 in that: the range required by the operating regulations in step 2 cannot exceed the rated load of the unit, nor can it be lower than the minimum load for maintaining stable combustion of the unit boiler.

[0050] Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0051] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the abrupt change phenomenon in step 2 means that if the unit load drops by 5MW-40MW instantaneously, it is determined that the unit has a sudden load failure.

[0052] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com