Supporting membrane of transmission electron microscope sample and manufacturing method for transmission electron microscope sample

A technology of electron microscope and manufacturing method, applied in the manufacture of discharge tubes/lamps, electrode system manufacturing, circuits, etc., can solve the problems that restrict the use of support films, and achieve the effects of strong practical application value, thin thickness, and strong mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

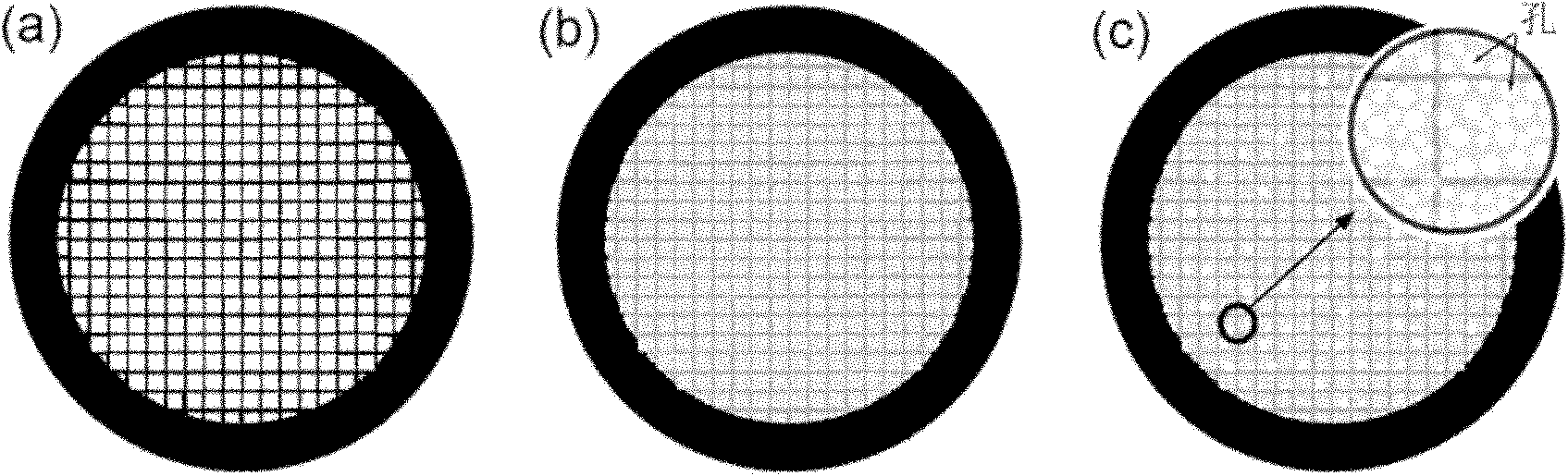

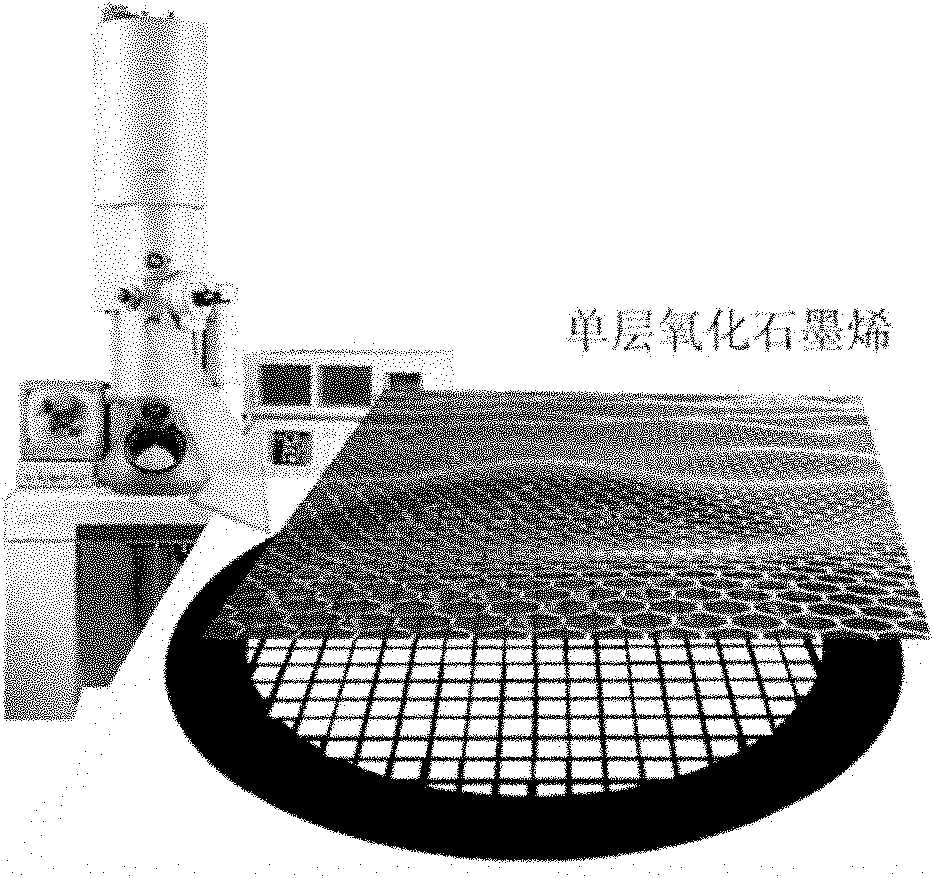

[0031] 1. Preparation of monolayer graphene oxide sample support film

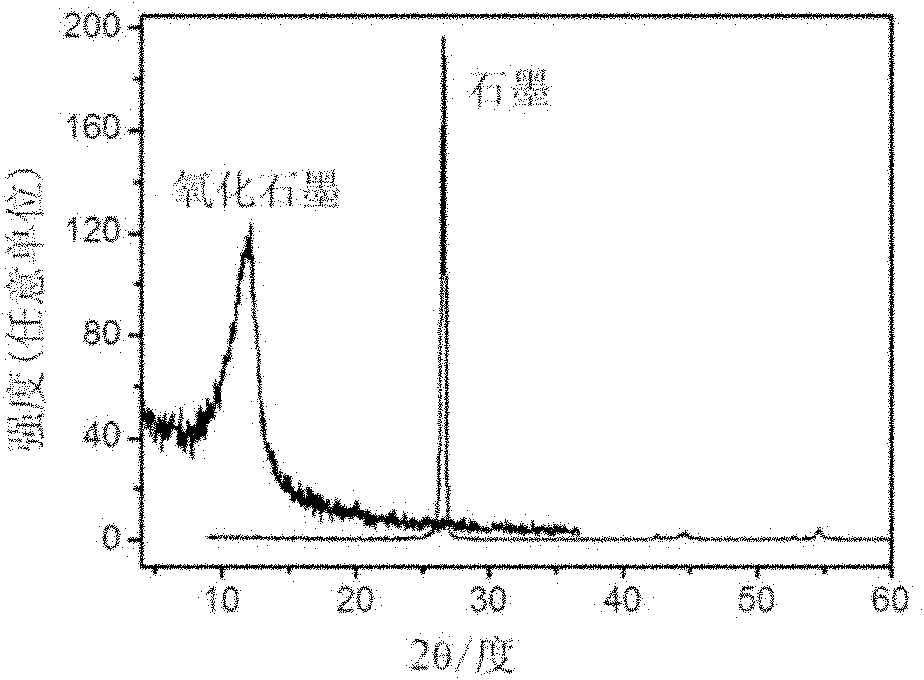

[0032] 1.1 Synthesis of graphene oxide

[0033] 1.1.1 Oxidation of graphite

[0034] The oxidation of graphite adopts the modified Hummers method. In order to ensure that the obtained graphene oxide maintains a certain electrical conductivity, the oxidation process is limited within two days. Graphite as a raw material is a 325-mesh powder with a purity of 99.9995%, purchased from Alfa Aesar, and chemical reagents such as potassium permanganate, sodium nitrate, concentrated sulfuric acid, hydrochloric acid, and hydrogen peroxide were purchased from Nanjing Chemical Reagent Company.

[0035] Take 2g of graphite powder, mix it with 3.75g of sodium nitrate and place it in a large beaker; install an electric stirrer, and keep the stirrer working continuously throughout the oxidation process. Slowly pour 170mL of concentrated sulfuric acid into it, and keep stirring for 2 hours to make the reagents mix evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com