Automatic large engine part butting device

A technology of automatic docking and large parts, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc. It can solve the problem that the attitude of level, pitch and yaw cannot be accurately identified, and the simple docking device has low precision and cannot be realized. Automatic operation and other issues to achieve the effect of reducing quality and safety hazards, reducing labor intensity, and enhancing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

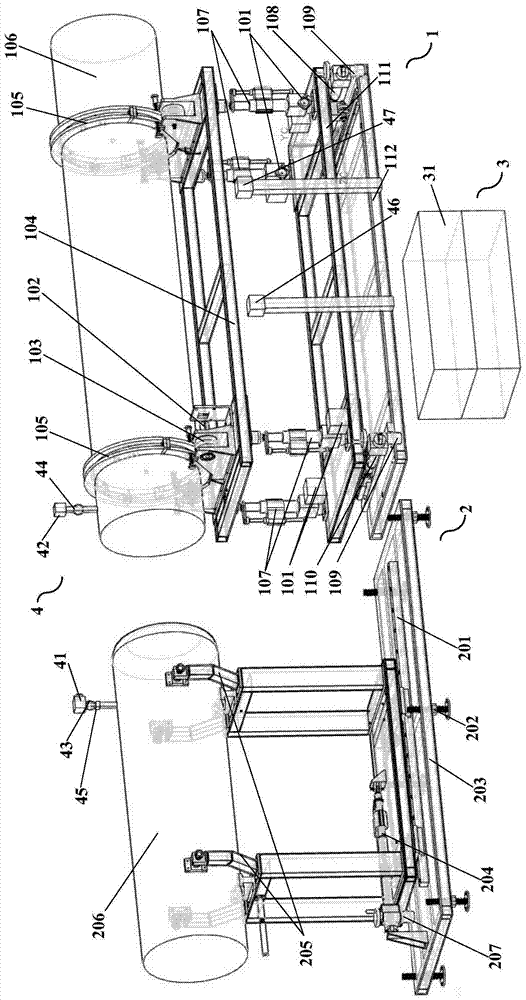

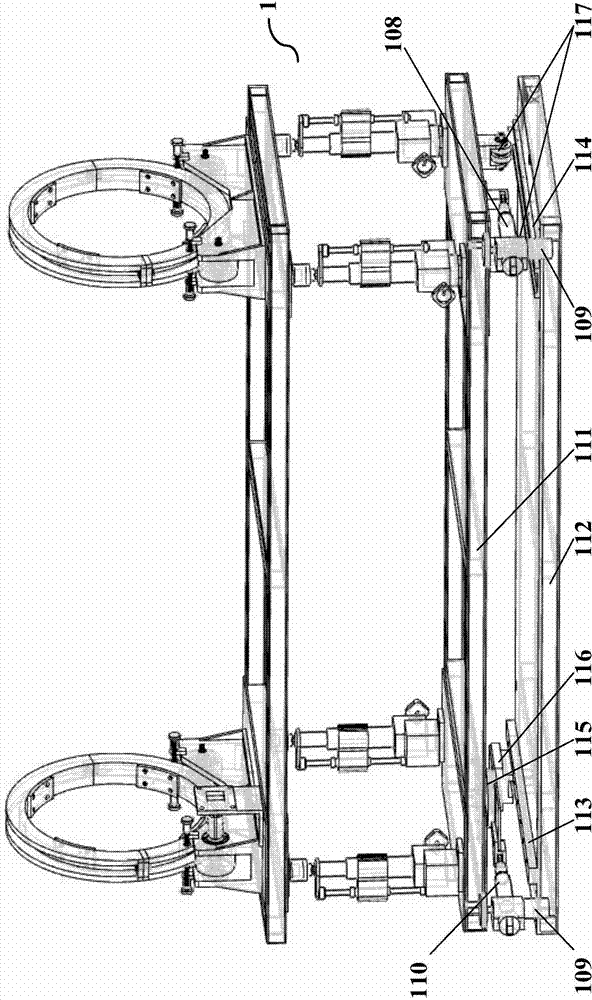

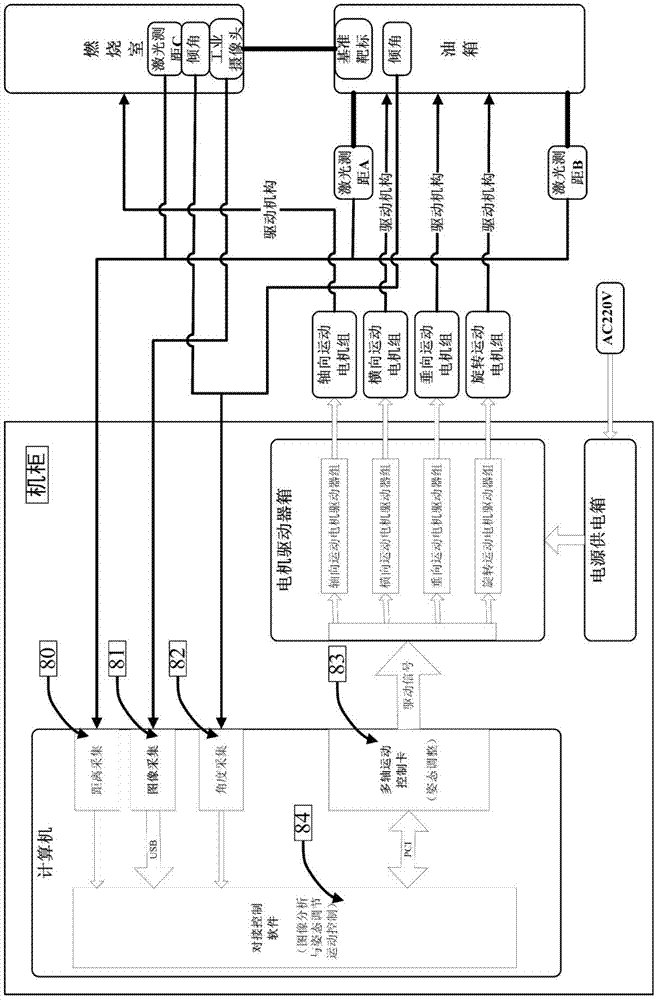

[0026] as attached figure 1 As shown, an automatic docking device for large parts of an engine of the present invention includes a motion docking bracket assembly 2, an attitude adjustment bracket assembly 1, a sensor assembly 4 and a computer 31, wherein the motion docking bracket assembly includes a guide rail plate 203, a height adjustment Bolt 202, combustion chamber clamping mechanism 205, axial guide rail 201 and axial drive mechanism 204, described axial guide rail 201 is fixedly connected on the upper surface of guide rail flat plate 203, height adjustment bolt 202 is installed on the lower surface of guide rail flat plate 203 and Between the ground; the axial movement motor 207 directly controls the axial drive mechanism 204, and realizes the axial position adjustment of the combustion chamber 206 along the guide rail 201. movement, while the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com