Device and method for dynamically observing and simulating behaviors of molten drops in electric slag remelting process

An electroslag remelting and droplet technology, which is applied in the field of metallurgy, can solve the problems of short-term droplet process, inability to observe the temperature dynamics of the molten pool, and multi-terminal changes in the shape of the molten droplet, so as to achieve the effect of promoting elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

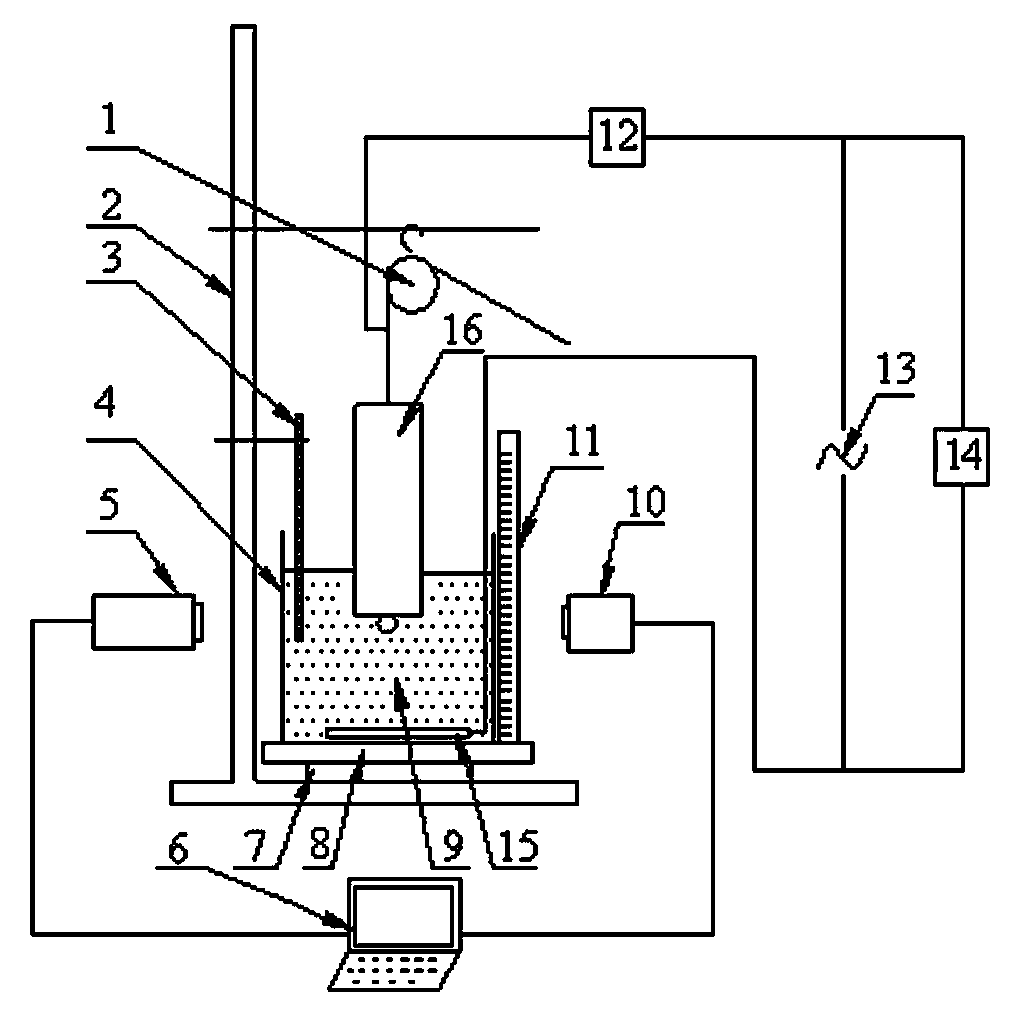

[0049] The structure of the device for dynamic observation and simulation of the droplet behavior in the electroslag remelting process is as follows: figure 1 As shown, it includes a quartz beaker 4, an insulating support 2 with an upper beam and a lower beam, a voltage regulator 13, an infrared thermal imager 5 and a high-speed camera 10; the quartz beaker 4 and the scale 11 are positioned on the platform; the upper beam is suspended There is a fixed pulley device 1, including a fixed pulley and a rope, and the Wood alloy round rod as a single consumable electrode 16 is suspended on the rope of the fixed pulley; meanwhile, the Wood alloy round rod is connected with the voltage regulator 13 through a wire, and the Wood alloy round rod Insert the bottom of the quartz beaker 4 inside as the conductive solution 9 of molten slag; the infrared thermal imager 5 and the high-speed camera 10 are placed outside the quartz beaker 4 and opposite to the bottom end of the Wood's alloy round...

Embodiment 2

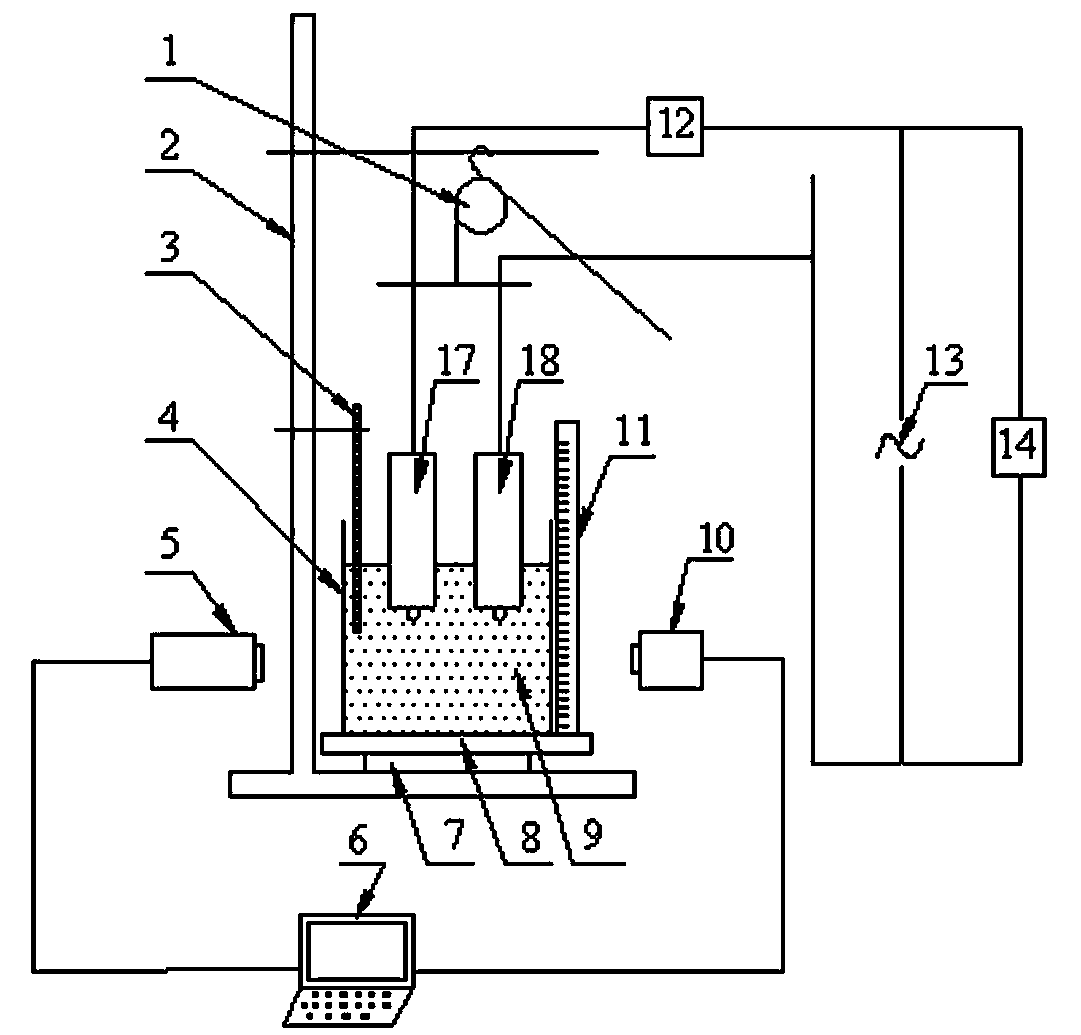

[0066] The structure of the device for dynamically observing and simulating the droplet behavior in the electroslag remelting process is as follows: figure 2 Shown, main part is identical with embodiment 1, difference is:

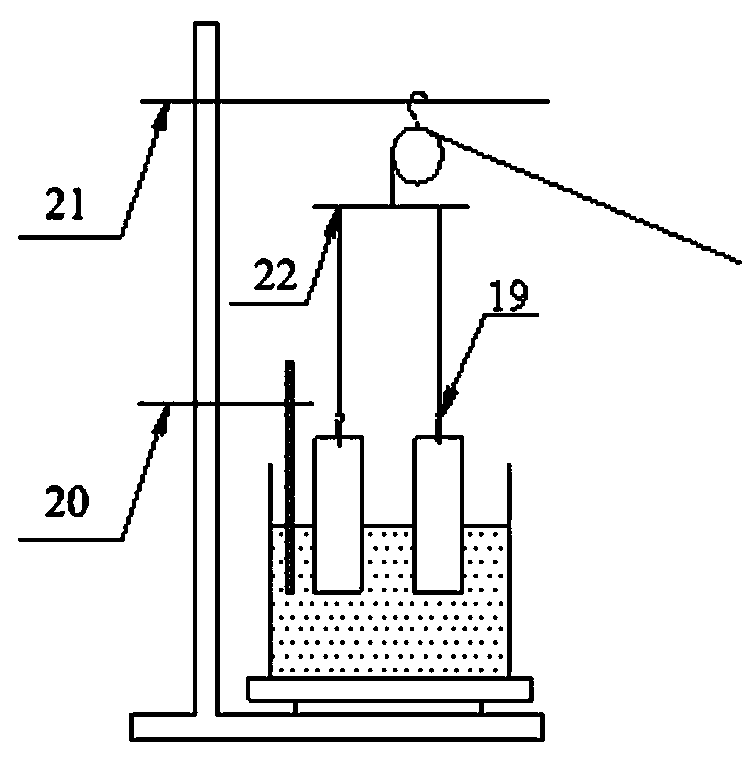

[0067] Local structures such as image 3 shown;

[0068] The Wood alloy round bar as the consumable electrode is divided into the first consumable electrode and the second consumable electrode, suspended on the movable beam and the movable beam suspended on the rope of the fixed pulley;

[0069] The first consumable electrode and the second consumable electrode are symmetrically suspended on the moving beam, and each Wood alloy round rod (consumable electrode) is connected to the two poles of the voltage regulator through wires;

[0070] Each Wood alloy round bar is connected with the moving beam through cotter pins;

[0071] The method of dynamically observing and simulating the droplet behavior in the electroslag remelting process is to use the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com