Rectifying unit structure

A rectifier unit and rectifier bridge technology, which is applied in the direction of transforming equipment structural parts, electrical components, electrical equipment structural parts, etc., can solve problems such as poor heat dissipation, complicated electrical connections, poor contact rectifier components, etc., and achieve rectification circuit Simple and clear, safe and reliable insulation protection, and reasonable pipeline layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

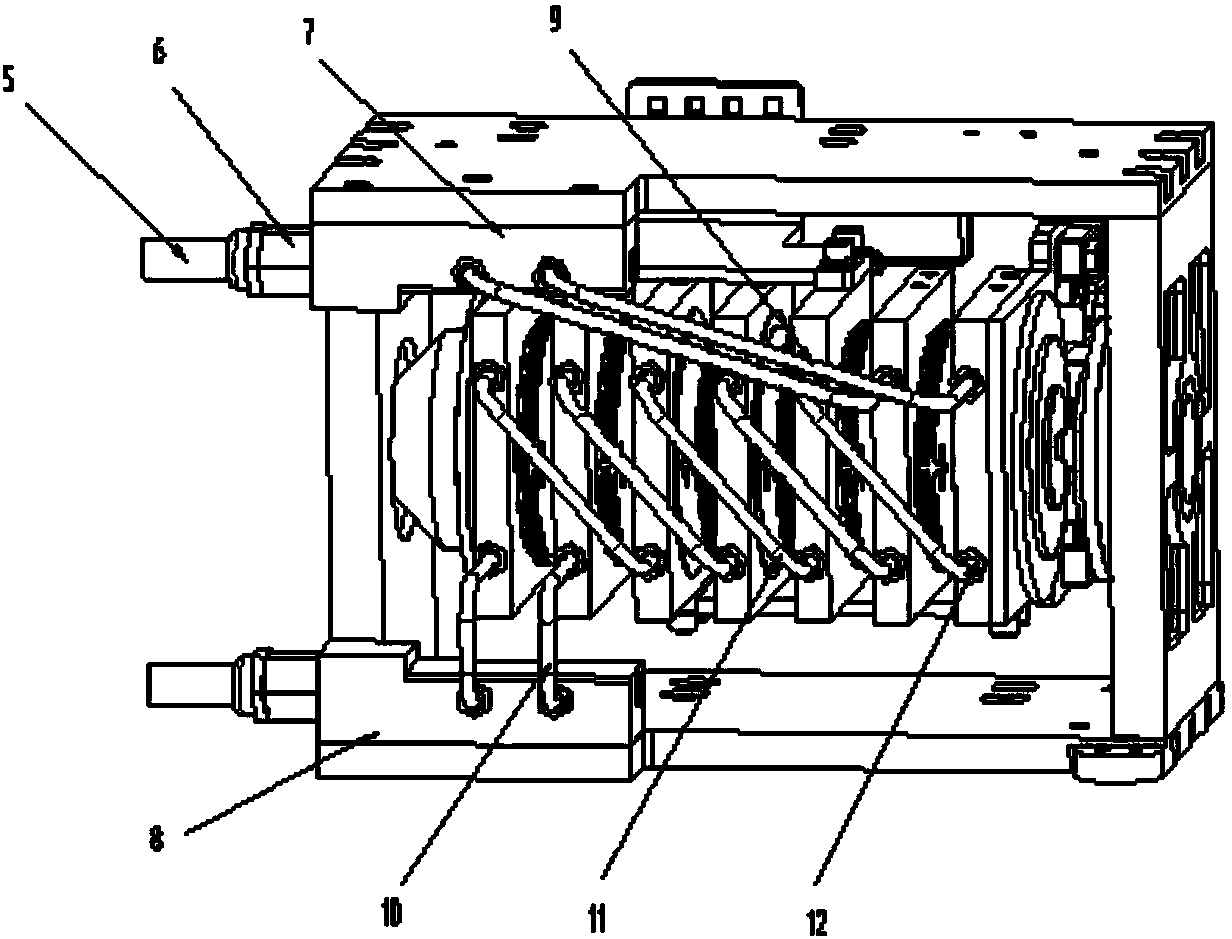

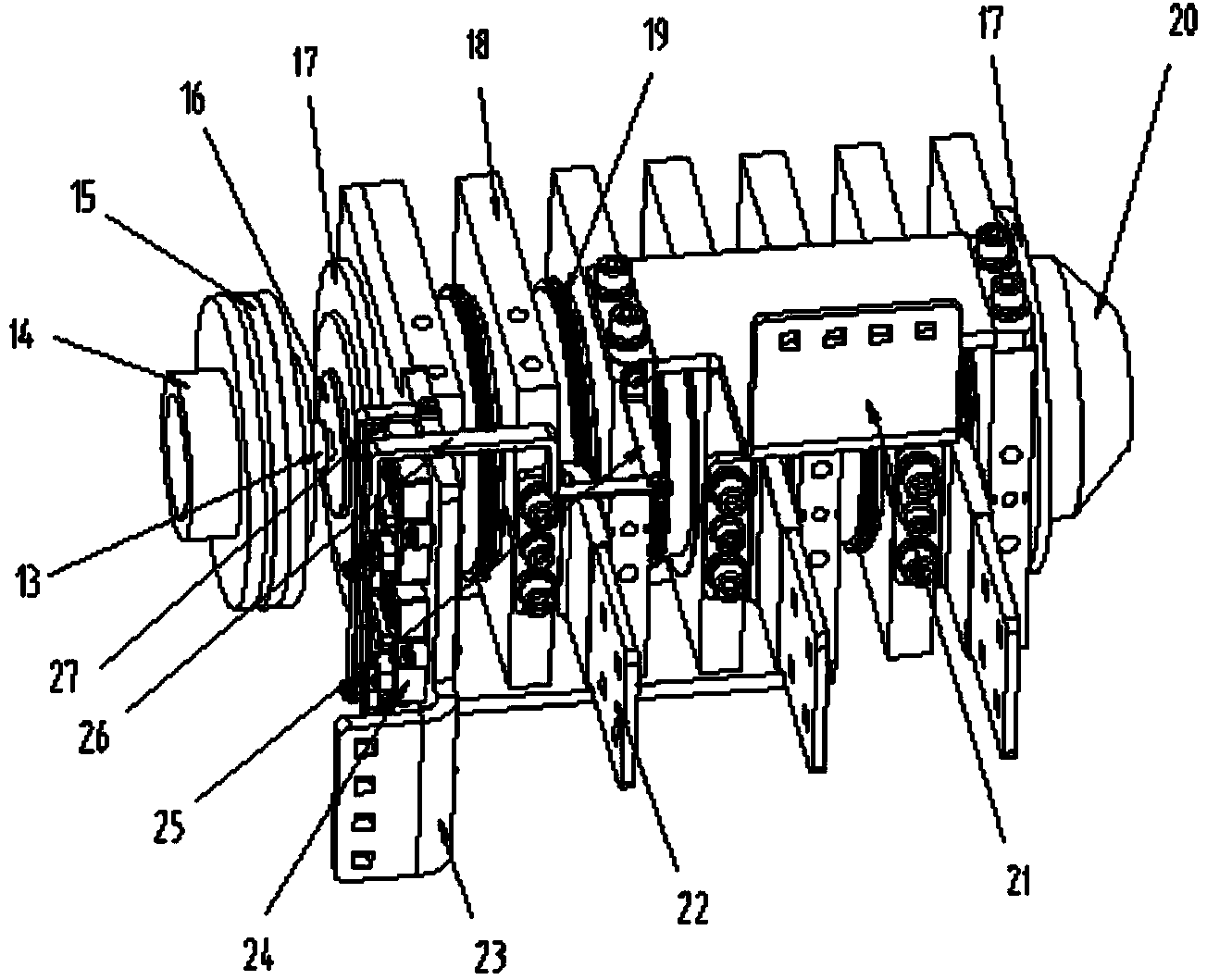

[0019] See figure 1 , The frame of the rectification unit includes a pressing side plate 1 , an upper plate 2 , a pressing side plate 3 and a lower plate 4 . The compression side plate 1, the compression side plate 3 and the upper plate 2 and the lower plate 4 are connected by high-strength bolts; the compression side plate 1 and the compression side plate 3 are provided with grooves, on the basis of ensuring the strength The structural weight is effectively reduced, and there are mounting holes and pin holes for the string pressing mechanism; the upper plate 2 is provided with the mounting holes for the water channel 7; the lower plate 4 is provided with the mounting holes for the water channel 8; There is a tool hole for easy internal installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com