Multi-group layered submerged impinging steam reactor

An impingement flow reactor, multi-component technology, applied in chemical/physical/physicochemical nozzle reactors, chemical methods for reacting liquids, chemical instruments and methods, etc., can solve the problem of not fully reflecting the advantages of impinging flow , Limiting the application of impinging flow technology, high manufacturing cost of propellers, etc., to achieve the effect of improving the level of liquid phase micro-mixing, facilitating processing, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

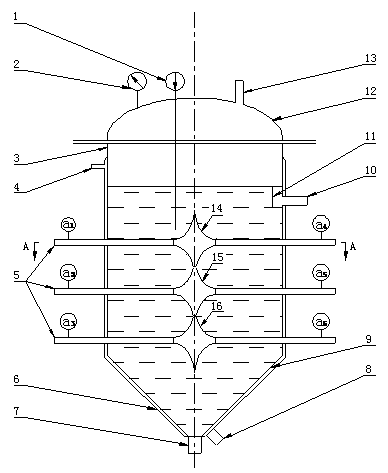

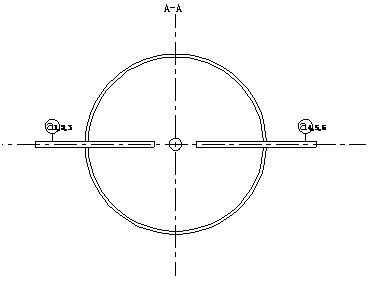

[0020] figure 1 It is a structural schematic diagram of the multi-component layered submerged impinging flow reactor (mixer) of the present invention.

[0021] In the figure: 1-thermometer, 2-pressure gauge, 3-kettle body, 4,8-heat exchange medium inlet and outlet, 5-feed inlet, 6-heating or cooling jacket, 7-outlet, 9- Conical bottom, 10-overflow port, 11-overflow weir, 12-top cover, 13-gas or steam outlet, 14,15,16-impact zone, (a)-(b) takeover position.

[0022] The present invention is composed of a kettle body 3, a feed pipe 5, a conical bottom 9, a top cover 12 and other parts, the main processing material is stainless steel, the shape of the kettle body 3 is a vertical cylinder, and the upper part adopts an oval head as the top cover 12. The lower part is a conical hollow cylinder, that is, the conical bottom 9, and the outer wall is provided with a heat exchange jacket 6. The top cover is provided with a gas outlet 13, a pressure gauge 2 and a thermometer 1, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com