Axial-flow coaxial film tube micro-bubble homogenization device

A micro-bubble, axial-flow technology, used in flotation water/sewage treatment, etc., can solve the problems of purification efficiency, low power consumption, and power consumption costs that cannot be ignored.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

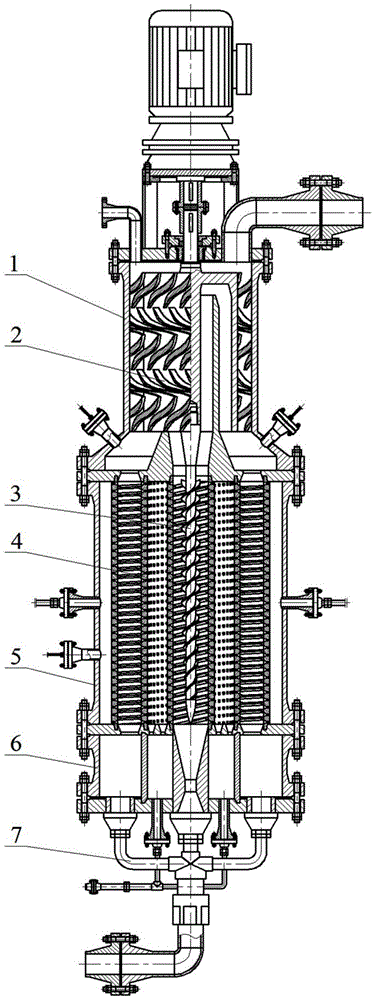

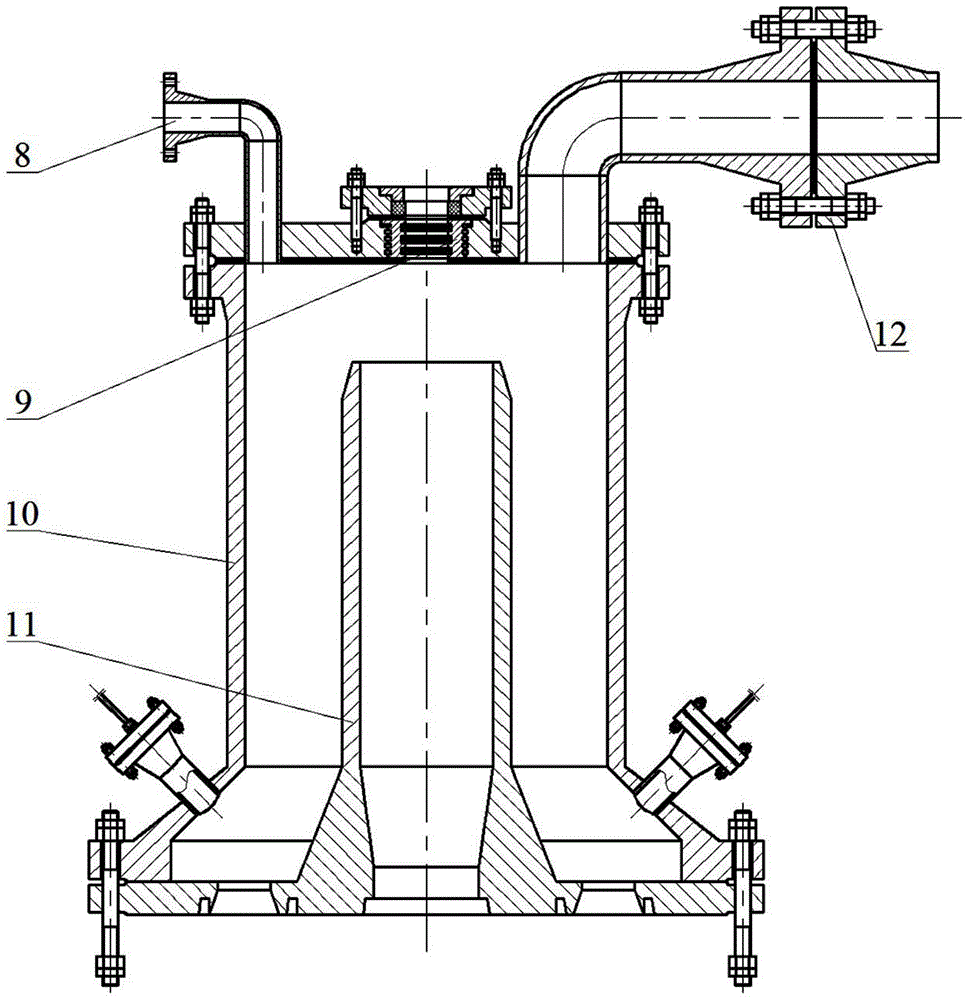

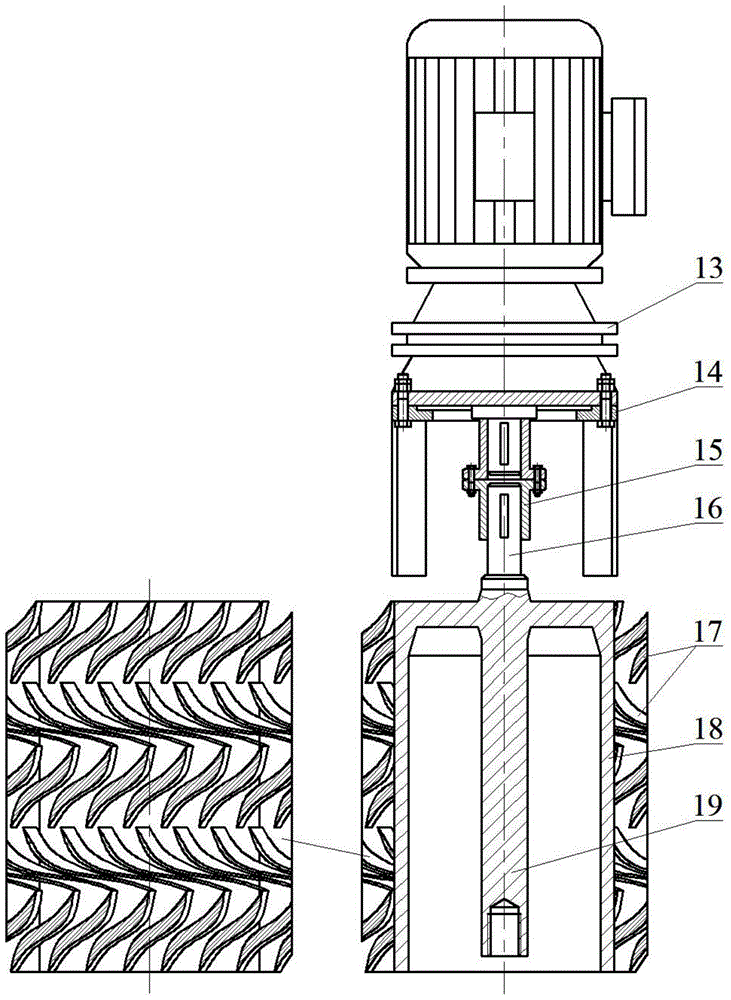

[0037] exist figure 1 Among them, the axial-flow coaxial membrane tube micro-bubble homogenization device consists of a crushing cylinder 1, a pressurized homomixer 2, a swirling fluid 3, a membrane tube assembly 4, a foaming cylinder 5, a pressure stabilizing cylinder 6, and a gas-liquid supplier 7 It is composed of a foaming homogeneous mixing control system. When assembling, first connect the liquid supply manifold and the lower gas supply manifold of the gas-liquid supplier 7 to the lower part of the pressure regulator cylinder 6 through the supply plate, then put the pressure regulator inner cylinder of the pressure regulator cylinder 6 into the pressure regulator outer cylinder and The connection between the pressure regulator cylinder 6 and the foam cylinder 5 is completed through the flange plate and the partition plate, and then the membrane tubes of the membrane tube assembly 4 are placed in the foam cylinder 5 in sequence, and the upper gas supply pipe of the gas-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com