Automatic production process of raw material wires of pneumatic row nails

A technology of manufacturing process and raw material wire, which is applied in the field of automatic manufacturing process of air nail raw material wire, can solve problems such as low efficiency, large manpower demand, and complicated manufacturing process, and achieve high production efficiency, high degree of automation, and improved safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

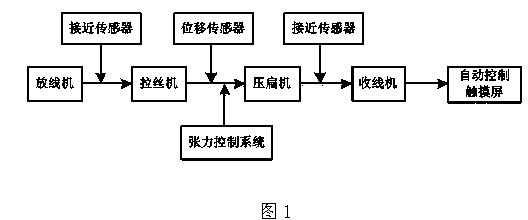

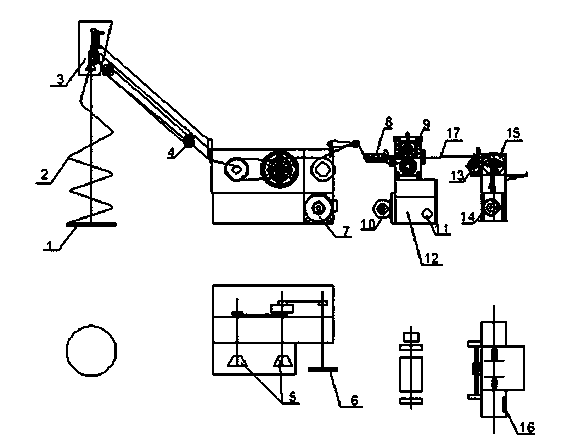

[0030] Such as figure 1 , figure 2 As shown, the automatic manufacturing system of a kind of air nail raw material wire according to the present invention adopts an automatic control system as a whole. The raw material wire 2 comes out from the pay-off machine 1, enters the wire drawing machine 7 through the automatic protection device 3 through the wire pulley 4, and passes through On the wire drawing machine 7, the drawing tower pulley 5 and the wire drawing die work at the same time, and the raw material wire 2 is stretched into the finished product model wire fine iron wire of the required specification. 10 provides power to start the flattening machine 9, and cools the rollers through the cooling circulation pump 11 and the cooling liquid storage tank 12 to ensure that the temperature will not be too high, and then the thin iron wire will be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com