3D (3-dimensional) print head for metal melt extrusion molding

A technology of extrusion molding and metal melting, which is applied in the field of 3D printing head and metal melting extrusion molding, which can solve the problems that have not been reported on the design of 3D printing head, and achieve the effect of avoiding excessive heat transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

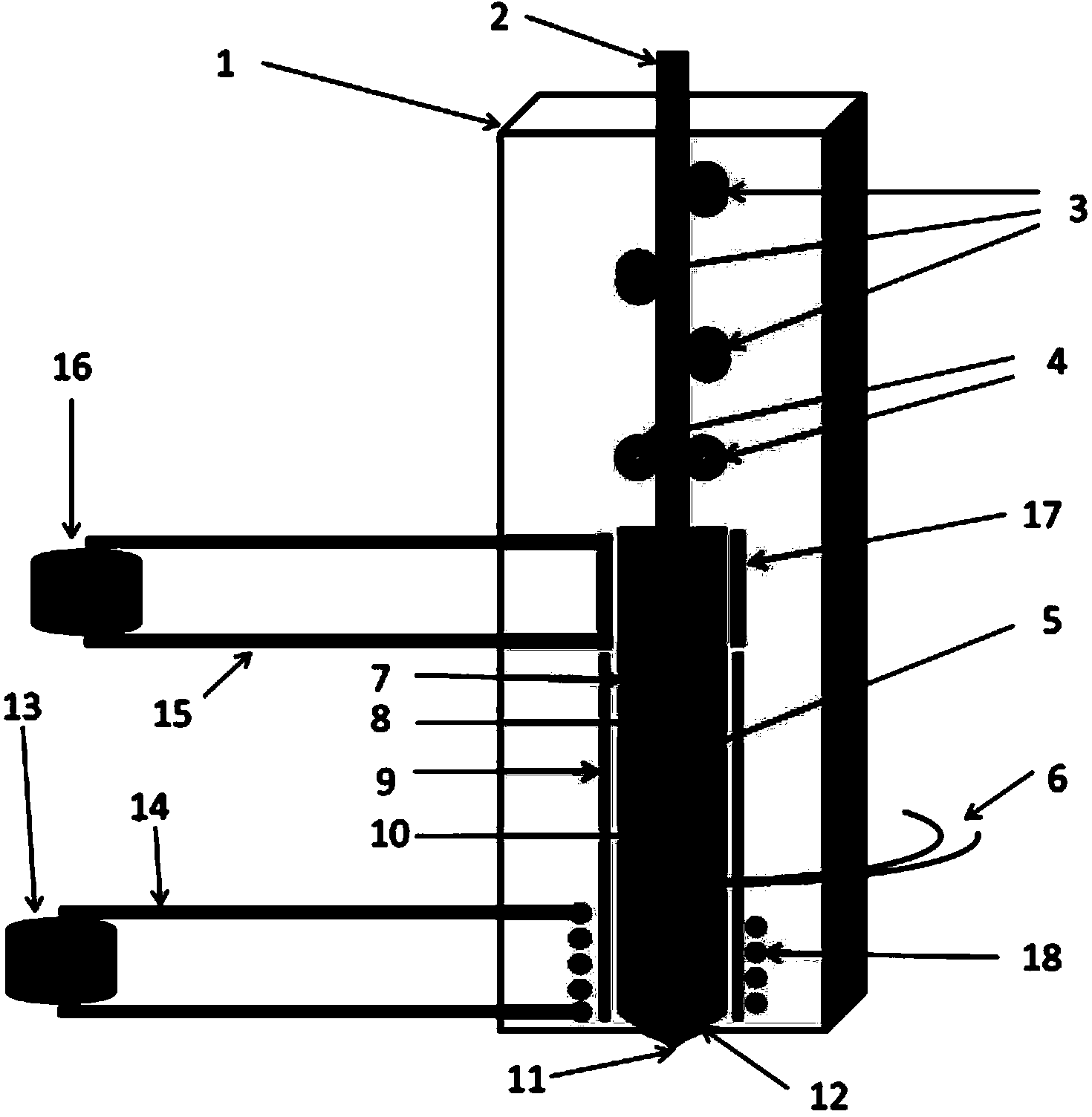

[0019] Such as figure 1 As shown, the 3D printing head for metal melt extrusion molding according to the present invention includes a housing 1, a raw material passage, a heating system, a cooling system and a temperature control system. The raw material passage is located inside the housing 1 and includes a raw material inlet, Alignment wheel 3, transfer roller 4, elongated hollow crucible 7 (the inner wall 8 of crucible 7 is smooth in this embodiment, less to metal movement / flow resistance) and raw material outlet 11, described raw material outlet 11 is provided with for The heat insulating ring 12 that prevents the heat transfer between the crucible 7 and the metal melt and the outside world. The metal raw material 2 enters the channel from the raw material inlet, and is corrected by the collimation wheel 3. The molten metal leaves the channel from the raw material outlet 11; the outside of the crucible 7 is coated with a heat shield 9 near the raw material outlet 11, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com