A kind of special herbicidal film for fruit trees and preparation process thereof

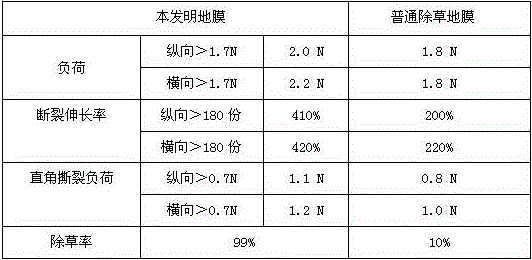

A technology for herbicidal film and fruit trees, applied in the field of special herbicidal film for fruit trees and its preparation process, can solve the problems of difficult mixing of various components, complicated process of herbicidal film, difficulty in quality assurance, etc., to ensure stability and reduce added materials. The number of times, the effect of tension enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Formula: A special weeding film for fruit trees, made of the following raw materials in mass percentage: 80% linear low-density polyethylene; 4% low-density polyethylene; 6% aging-resistant masterbatch; 10% light-blocking black masterbatch. The anti-aging masterbatch is made by mixing and granulating the raw materials in the following weight ratio: 13 parts of hindered amine light stabilizer, 6.5 parts of composite antioxidant, and 6.5 parts of benzotriazole ultraviolet absorber.

[0025]Preparation process: It specifically includes the following steps. According to the above mass percentage, first add linear low-density polyethylene resin into the mixer, then add low-density polyethylene resin, then add aging-resistant masterbatch and light-blocking black masterbatch, stir and mix thoroughly Uniform; Siemens PLC terminal software is used to input the control temperature of the temperature controller, the length sensor to control the width, and the tensile tester to cont...

Embodiment 2

[0027] Formula: a special weeding film for fruit trees, made of the following raw materials in mass percentage: linear low-density polyethylene 65%; low-density polyethylene 10%; aging-resistant masterbatch 10%; light-blocking black masterbatch 15%; The anti-aging masterbatch is made by mixing and granulating the raw materials in the following weight ratio: 7 parts of hindered amine light stabilizer, 3.5 parts of composite antioxidant, and 4.5 parts of benzotriazole ultraviolet absorber.

[0028] Preparation process: It specifically includes the following steps. According to the above mass percentage, first add linear low-density polyethylene resin into the mixer, then add low-density polyethylene resin, then add aging-resistant masterbatch and light-blocking black masterbatch, stir and mix thoroughly Uniform; Siemens PLC terminal software is used to input the control temperature of the temperature controller, the length sensor to control the width, and the tensile tester to co...

Embodiment 3

[0030] Formula: a special weeding film for fruit trees, made of the following raw materials in mass percentage: 70% linear low-density polyethylene; 10% low-density polyethylene; 8% aging-resistant masterbatch; 12% light-blocking black masterbatch; The anti-aging masterbatch is made by mixing and granulating the raw materials in the following weight ratio: 10 parts of hindered amine light stabilizer, 5 parts of composite antioxidant, and 5.5 parts of benzotriazole ultraviolet absorber.

[0031] Preparation process: It specifically includes the following steps. According to the above mass percentage, first add linear low-density polyethylene resin into the mixer, then add low-density polyethylene resin, then add aging-resistant masterbatch and light-blocking black masterbatch, stir and mix thoroughly Uniform; Siemens PLC terminal software is used to input the control temperature of the temperature controller, the length sensor to control the width, and the tensile tester to cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com