Safety valve silencer

A muffler and safety valve technology, applied in the direction of valve details, valve devices, valve energy absorption devices, etc., can solve the problems of poor noise reduction effect, low working reliability, poor air flow, etc., and achieve low power loss, Good noise reduction effect, smooth air intake and exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

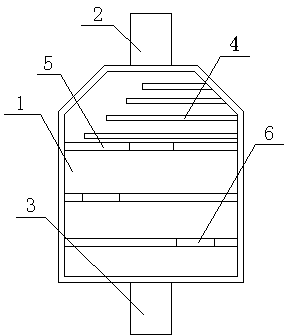

[0009] like figure 1 It is a structural schematic diagram of the present invention, a safety valve muffler, including a body 1, an air inlet 2, an air outlet 3, a partition 4, a sound-absorbing panel 5 and an air hole 6, one end of the body 1 is provided with an air inlet 2, and the other One end is provided with an air outlet 3 , the upper end of the body 1 is provided with a partition 4 , and at least three sound-absorbing panels 5 are arranged inside the body 1 , and air holes 6 are provided on the sound-absorbing panels 5 .

[0010] When in use, the gas enters the body 1 from the air inlet 2, the lengths of the partitions 4 are different, and they are arranged in steps, and then pass through the air holes 6 on the sound-absorbing panels 5, and the air holes 6 of the sound-absorbing panels 5 are staggered, and finally pass through Air outlet 3 discharges. This kind of safety valve muffler has a simple, compact and reasonable structure, convenient and fast assembly, and rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com