Heat exchanger for cooling a vehicle battery, in particular for hybrid or electric vehicles

A technology of hybrid electric vehicles and heat exchangers, applied in heat exchange equipment, secondary batteries, indirect heat exchangers, etc., can solve the problems of low energy efficiency of motor vehicles, and achieve the effect of reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

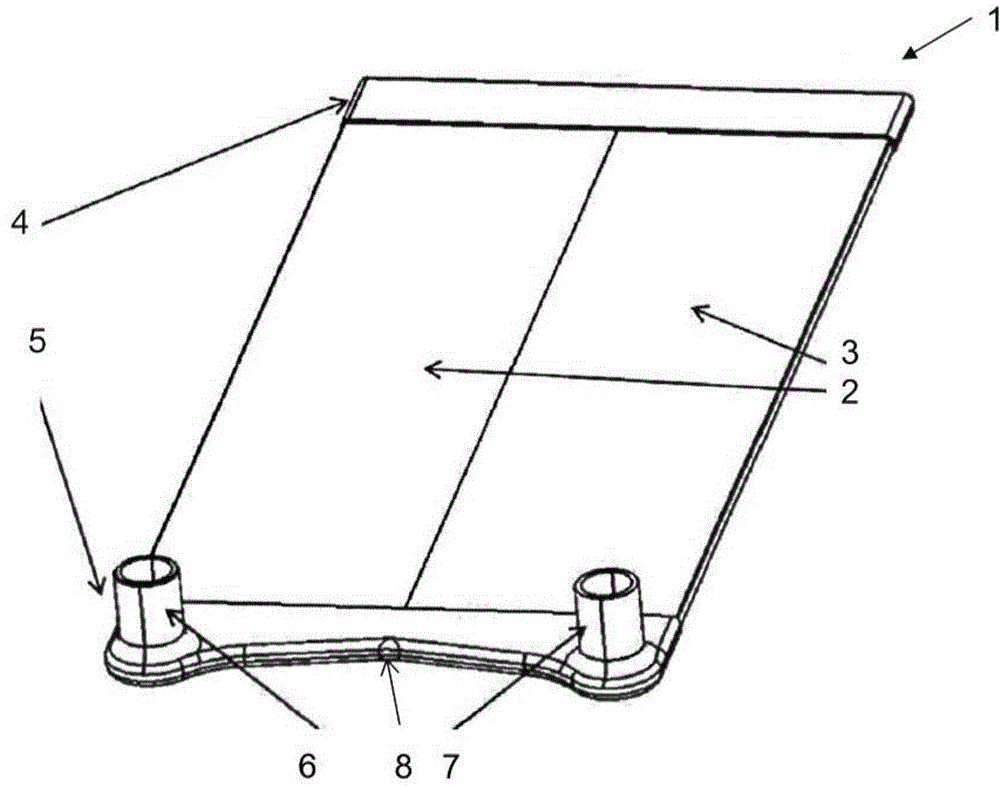

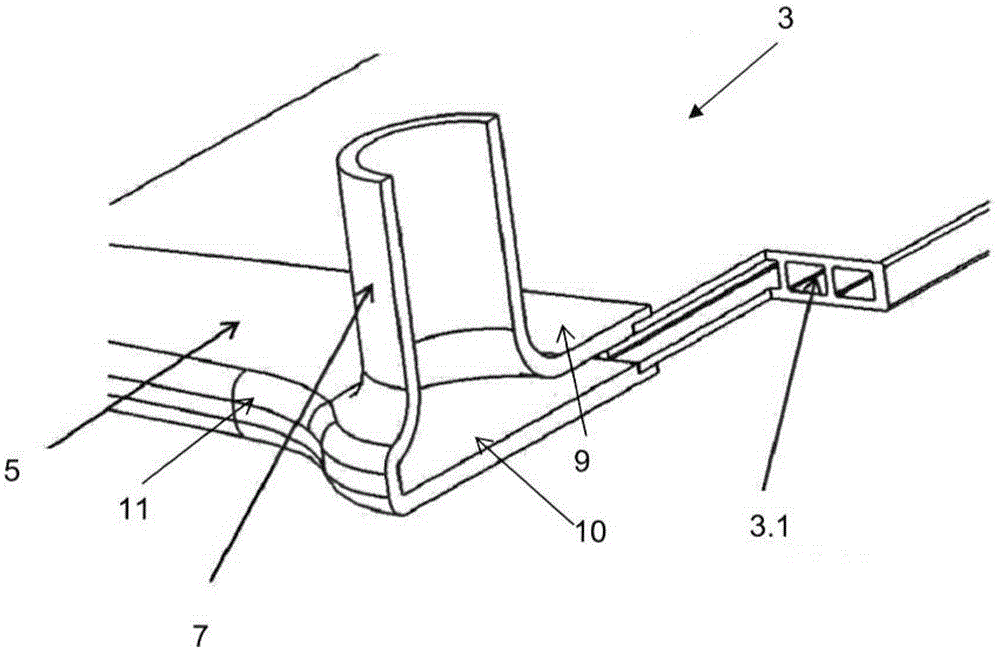

[0025] figure 1 A first exemplary embodiment of a heat exchanger according to the invention is shown. The heat exchanger 1 here comprises two multi-lumen tubes 2 , 3 which are arranged between two fluid collectors 4 , 5 . The two multilumen tubes 2 , 3 and the two fluid collectors 4 , 5 are here made entirely of plastic. figure 1 The heat exchanger 1 shown is designed as a U-shaped flow cooler. This heat exchanger 1 is characterized in that the inlet branch 6 for the fluid of the cooling medium and the outlet branch 7 for this fluid are arranged on the same fluid collector 5 . The inlet branch 6 is arranged here in the region of the first multi-lumen tube 2 , while the outlet branch 7 lies opposite the second multi-lumen tube 3 .

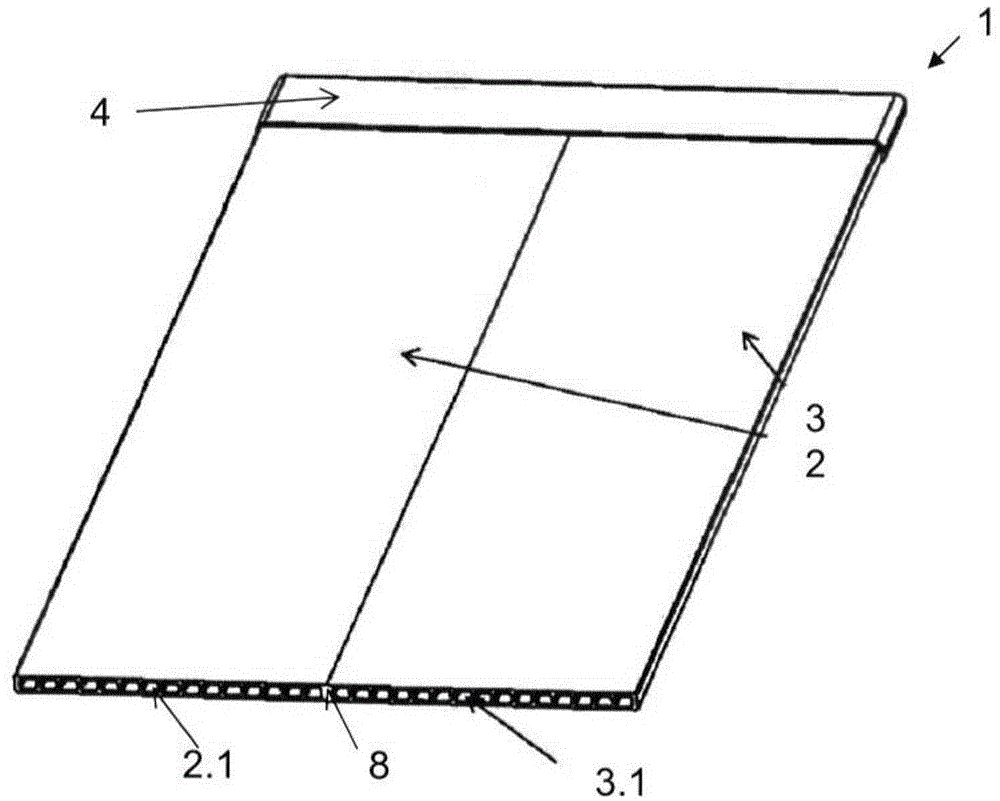

[0026] figure 2 Parts of the multi-lumen tubes 2 and 3 are shown, from which it can be seen that each multi-lumen tube 2, 3 has a plurality of fluid channels 2.1 or 3.1. In the described U-shaped flow cooler, the fluid flows via the fluid coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com