Black tea fermentation device and black tea fermentation method based on same

The technology of a fermentation device and fermentation method is applied in the direction of tea treatment before extraction, etc. It can solve the problems of unstable tea quality, large temperature difference between fermentation rooms, and large area occupied by fermentation rooms, so as to achieve controllable fermentation temperature and humidity and save Fermentation area and the effect of shortening the fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

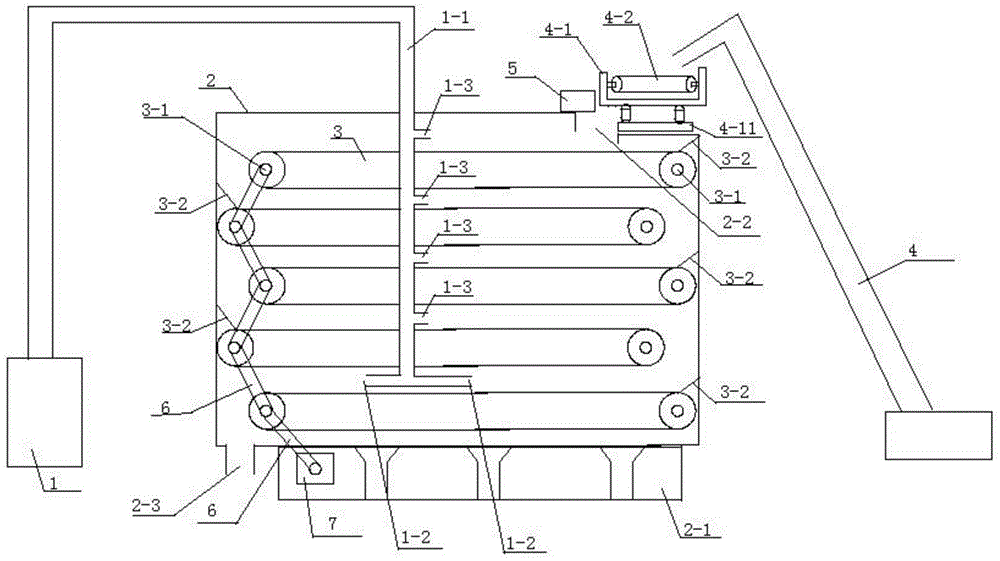

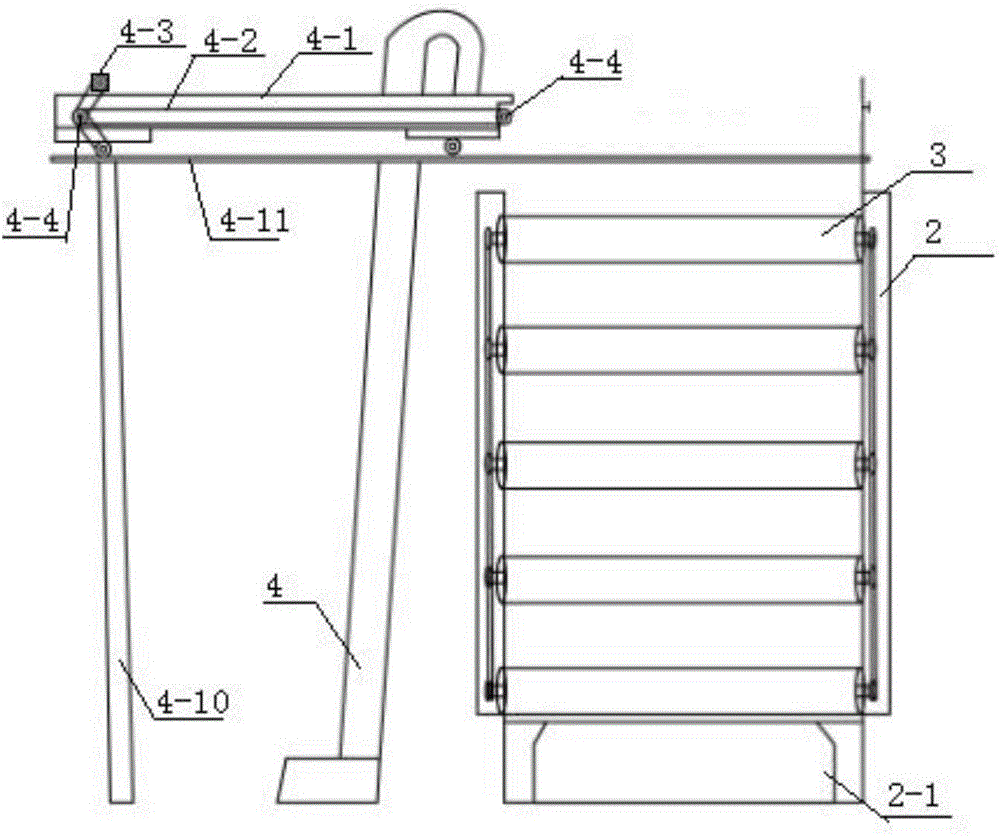

[0025] figure 1 A schematic structural view of the black tea fermentation device of the present invention is shown. Such as figure 1 As shown, the black tea fermentation device includes a steam boiler 1, a fermentation tank 2, a support 2-1 for supporting the fermentation tank 2, a fermentation bed 3, a feeding conveyor 4, a tea feeding device, a tea feeding truck 4-1, Tea throwing lane 4-11, leaf thickness equalizer 5, transmission chain 6 and motor 7, wherein, the steam boiler 1 is connected with the fermentation tank 2 through the pipeline 1-1, and the steam boiler 1 passes steam through The pipeline 1-1 is transported into the fermentation tank 2, and the lower end of the pipeline 1-1 is split into two first outlets 1-2, and the steam can be transported into the fermentation tank through the two first outlets 1-2 at the same time. Inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com