Production method of Gracilaria instant instant food

A technology of convenience food and production method, which is applied in the field of food processing, can solve the problems of inability to adopt high temperature sterilization, poor color and taste, etc., and achieve the effects of improving safety and stability, reducing water activity, and improving high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

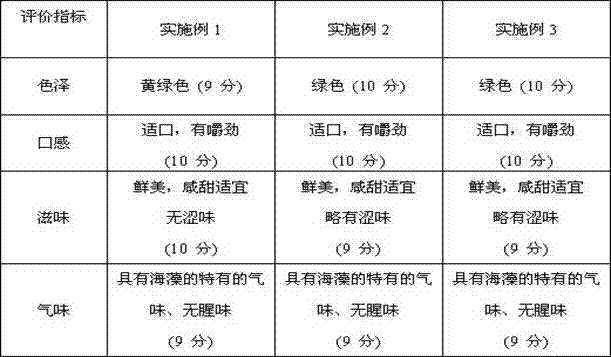

Examples

Embodiment 1

[0022] 500 g of fresh Gracilaria, blanched in about 15 L of boiling water for 1 min, quickly transferred to ice water to cool to room temperature, drained, soaked in 25 L of seasoning liquid for 3 h, and then dehydrated in a centrifuge 5min (rotating speed 3000rpm), then put into -5 DEG C and freeze 24 h, after thawing, utilize centrifuge dehydration 5min again (rotating speed 3000rpm), the moisture content of Gracilaria is now 72.6%, then add Gracilaria weight ( Weight after dehydration) 2% seasoning oil, stir and mix evenly, then cut into certain specifications, pack in bags of 100g per bag, vacuum pack, put in a water bath of 80°C for 120 s, and use ice water to quickly Cooling to the center temperature of the product is room temperature, and preparing Gracilaria instant instant food.

[0023] The component content of described primary seasoning liquid is: zinc sulfate is 0.1% (w / v), glutamine transaminase is 0.5% (w / v), calcium chloride is 0.1% (w / v), sorbitol 5% (w / v), t...

Embodiment 2

[0026] 500 g of fresh Gracilaria, blanched in about 10 L of boiling water for 3 minutes, quickly transferred to ice water to cool to room temperature, drained, soaked in 15 L of seasoning liquid for 12 hours, and then dehydrated in a centrifuge 2min (rotating speed 4000rpm), then put into -15 DEG C and freeze for 12 h, after thawing, utilize centrifuge dehydration 2min (rotating speed 4000rpm), this moment, the moisture content of Gracilaria is 74.8%, then add Gracilaria weight ( Weight after dehydration) 5% seasoning oil, stir and mix evenly, then cut into certain specifications, pack in bags of 60g per bag, vacuum pack, put in a water bath of 85°C for 30 s, and use ice water to quickly Cooling to the center temperature of the product is room temperature, and preparing Gracilaria instant instant food.

[0027] The component content of described primary seasoning liquid is: zinc acetate is 0.5% (w / v), glutamine transaminase is 2.0% (w / v), calcium chloride is 0.5% (w / v), sorbit...

Embodiment 3

[0030] Put 500 g of fresh Gracilaria in about 12.5 L of boiling water for 2 minutes, then quickly transfer to ice water to cool to room temperature, drain and soak in a seasoning solution for 6 hours, and then use a centrifuge to dehydrate for 3 minutes ( Rotating speed 3500rpm), put into -10 DEG C and freeze 16 h again, after thawing, utilize centrifuge dehydration 3min again (rotating speed 3500rpm), the moisture content of Gracilaria is 70.3% at this moment, then add Gracilaria weight 3% Seasoning oil, stirred and mixed evenly, then cut into certain specifications, bagged according to 80g per bag, vacuum-packed, placed in a water bath at 83°C for 60 seconds, and cooled rapidly with ice water until the center temperature of the product is room temperature , prepared as Gracilaria instant instant food.

[0031] The component content of described primary seasoning liquid is: zinc acetate is 0.3% (w / v), glutamine transaminase is 1.2% (w / v), calcium chloride is 0.3% (w / v), sorbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com