Fruit and vegetable drying device

A technology for drying equipment, vegetables and fruits, applied in application, food processing, food science and other directions, can solve the problems of high energy consumption of the whole machine, low utilization rate of heat energy, insufficient drying of raw materials of vegetables and fruits, etc., to achieve sufficient drying effect, energy saving, The effect of improving the energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

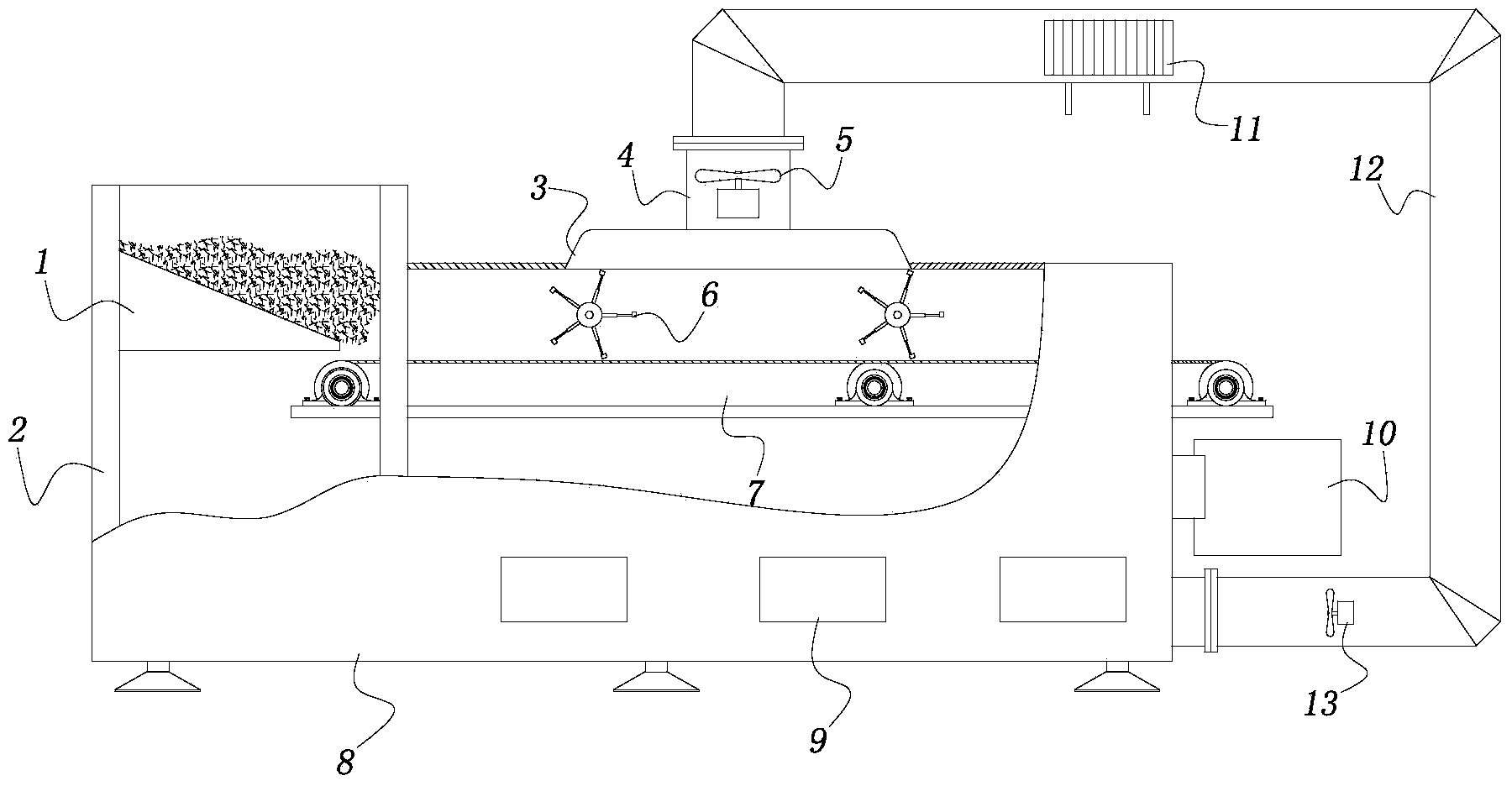

[0015] See figure 1 , the present invention includes a frame 2, the outside of the frame 2 is coated with a metal plate to form a sealed box 8, and a hopper 1 is arranged on the top of the head end of the box 8. The hopper 1 is used to hold the preliminarily air-dried vegetable and fruit raw materials. Such vegetable and fruit raw materials will not stick in the hopper 1 and flow smoothly.

[0016] In the actual configuration, the hopper 1 can have various forms: for example, it is made by welding a metal plate, and then welded and installed on the top of the frame 2 at the head end of the box body 8; A wedge block with a slope on the top and the inner wall of the casing 8 are formed, and a gap is left between the front end of the wedge block and the inner wall of the casing 8 to form a discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com