Ultrasonic-based centrifugal type bidirectional automatic-backwashing water-sediment separating device

A technology of automatic backwashing and separation of water and sand, applied in the fields of filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of difficulty, harm, restriction of popularization and application of fine-grained sediment treatment, and achieve excellent adjustability. , reduce wear and achieve the effect of filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

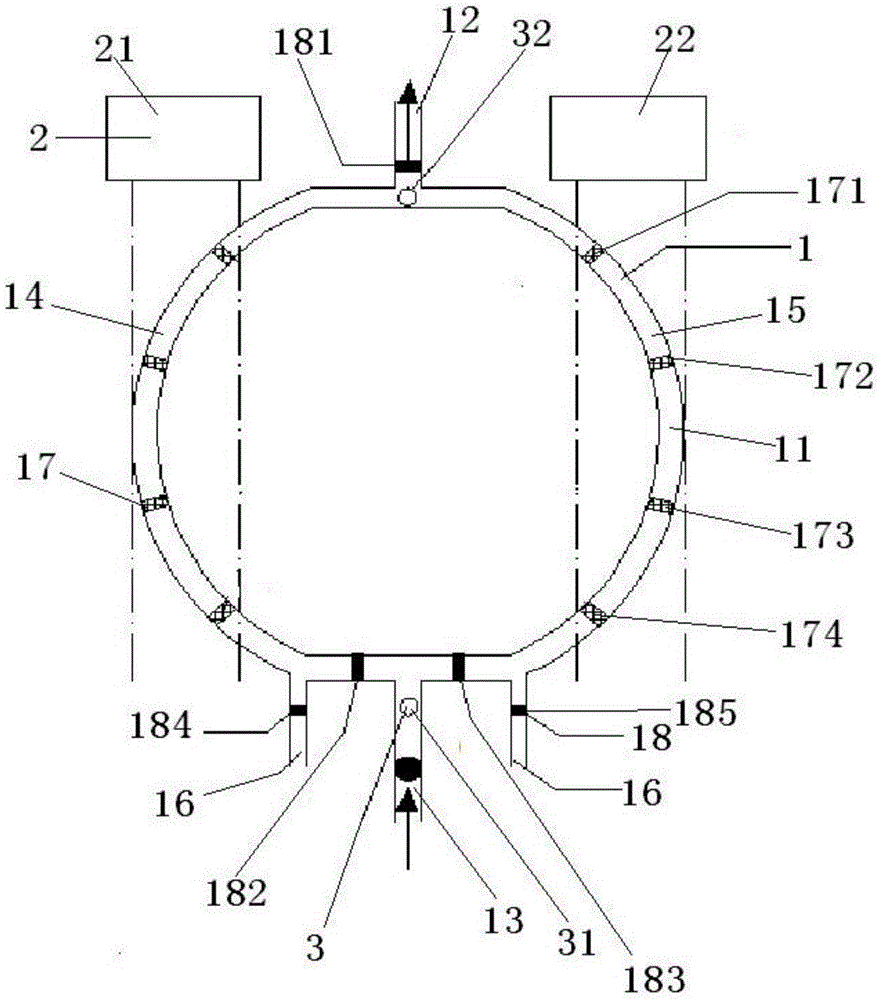

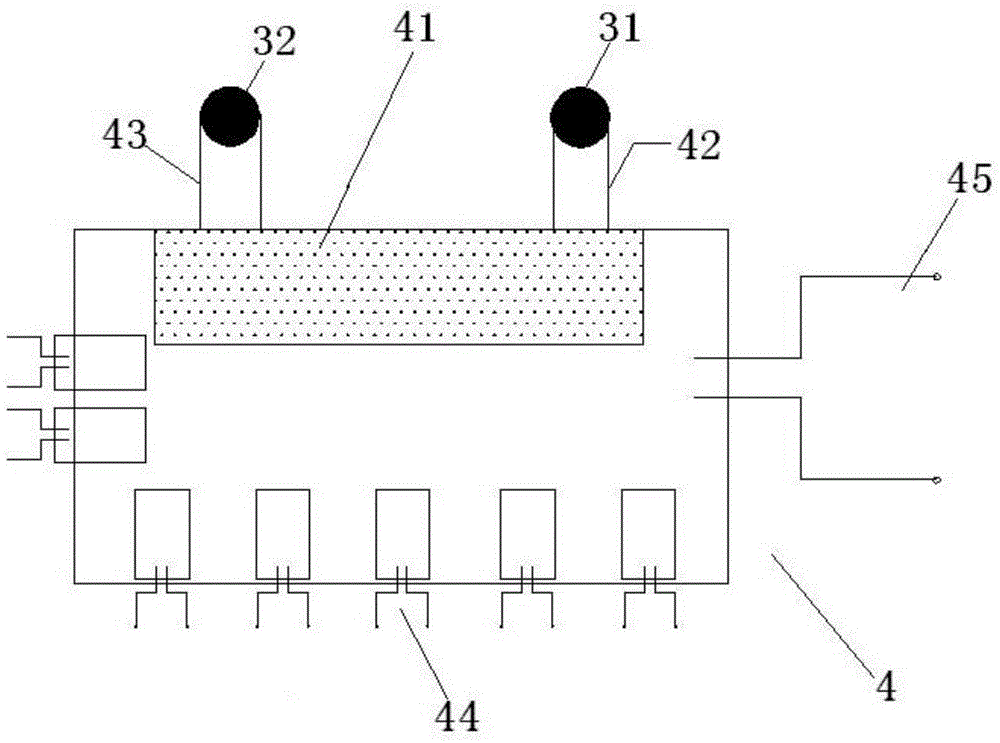

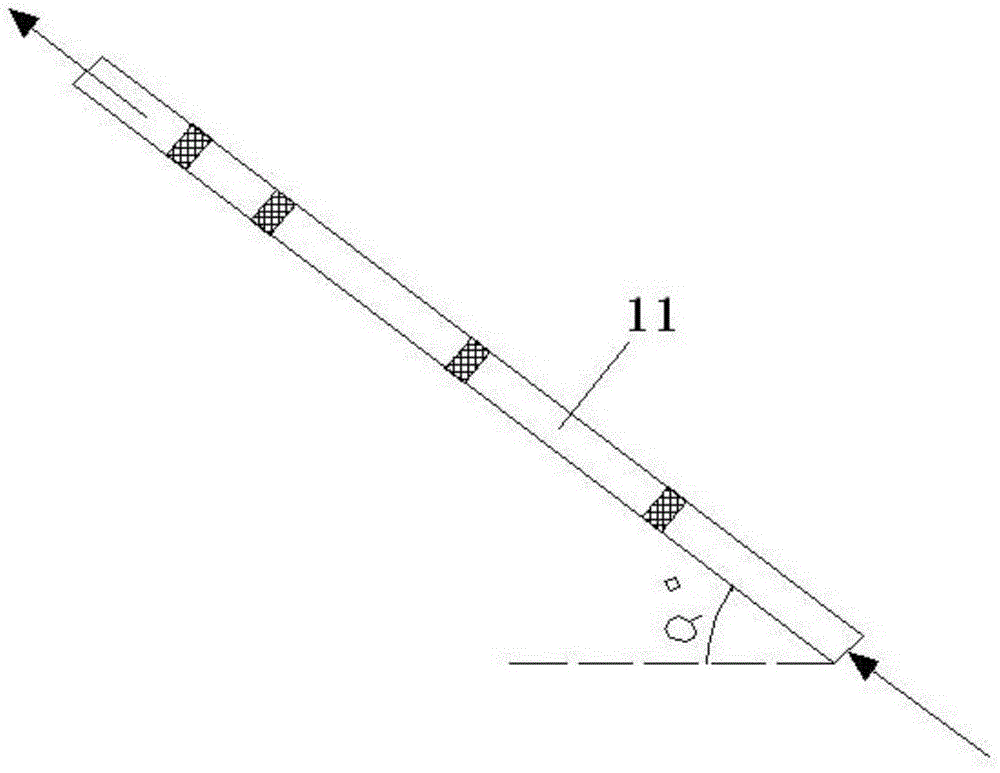

[0039] Such as Figure 1~6 As shown, a centrifugal two-way automatic backwashing water and sand separation device based on ultrasonic waves is characterized in that it includes: a pipeline unit 1, a vibration generating unit 2, a water flow monitoring unit 3 and an automatic control unit 4; the pipeline unit 1 Set in the vibration generating unit 2, the water flow monitoring unit 3 is set in the pipeline unit 1, the automatic control unit 4 is electrically connected to the vibration generating unit 2 and the water flow monitoring unit 3;

[0040] The pipeline unit 1 includes a semi-annular pipeline 11, the upper part of the semi-annular pipeline 11 is connected with a water outlet pipe 12, and the lower part of the semi-annular pipeline 11 is connected with a water inlet pipe 13, and the water outlet pipe 12 and the water inlet pipe 13 connect the semi-annular The annular pipe 11 is divided into a symmetrical left branch pipe 14 and a right branch pipe 15, the bottom of the le...

Embodiment 2

[0056] Such as Figure 1~6 As shown, a centrifugal two-way automatic backwashing water and sand separation device based on ultrasonic waves,

[0057] Another structure of the filter is:

[0058] 20 mesh is selected as the fourth layer of filter screen, which can filter out coarse sand particles, etc.;

[0059] Choose 80 mesh as the third layer, which can filter out most of the medium sand particles;

[0060] Choose 150 mesh as the second layer, which can filter out most of the fine sand particles;

[0061] Choose 250 mesh as the first layer, which can filter out most of the sediment particles and flocculent impurities.

[0062] All the other contents are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com