Machine-made-sand grain shape optimizing machine

A kind of sand and mechanism technology, applied in grain processing and other directions, can solve the problems that the fluidity, bulk density, gradation and other performance indicators of machine-made sand are difficult to meet, and affect the performance of concrete, so as to improve the fluidity and increase the compressive strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

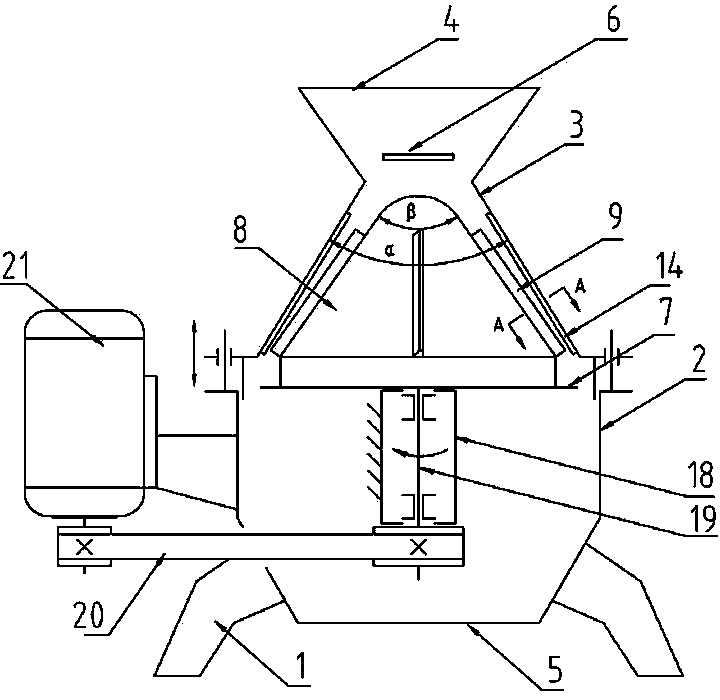

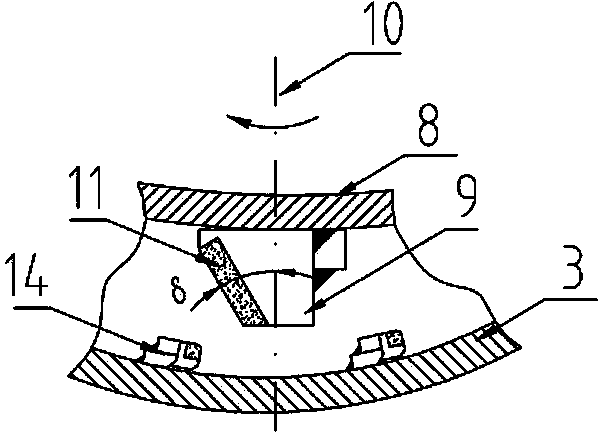

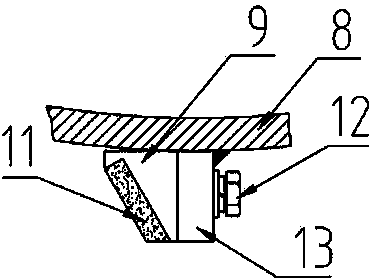

[0015] Such as figure 1 As shown, the machine-made sand particle shape optimization machine of the present invention includes a casing arranged on the machine base 1, the inner cavity of the casing is composed of a cylindrical lower chamber 2 and a conical upper chamber 3, and the feeding The mouth 4 is arranged on the top of the conical upper chamber 3, the discharge port 5 is arranged on the bottom of the cylindrical lower chamber 2, and a bulk material tray 6 is arranged below the feed inlet 4; the conical upper chamber The cone angle α of 3 is 70°, and the connection between the conical upper chamber 3 and the cylindrical lower chamber 2 is provided with a throwing tray 7, and a movable cone 8 is concentrically fixed on the upper surface of the throwing tray 7. The taper angle β of moving cone 8 is 65 °, and the maximum diameter of moving cone 8 is less than the diameter of throwing off material tray 7, and the diameter of throwing off material tray 7 is less than the diam...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap