High pressure fine water mist spray gun for SNCR (selective non-catalytic reduction) denitration system

A technology of high-pressure water mist and water mist nozzles, which is applied to spray devices, liquid spray devices, and dispersed particle separation, etc., can solve the problems of unsatisfactory use effect, large atomized particles, and easy wear and tear, and achieve good results. , high corrosion resistance, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

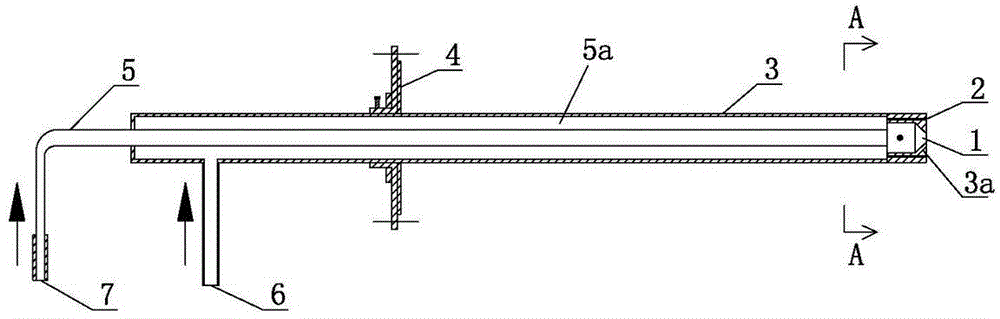

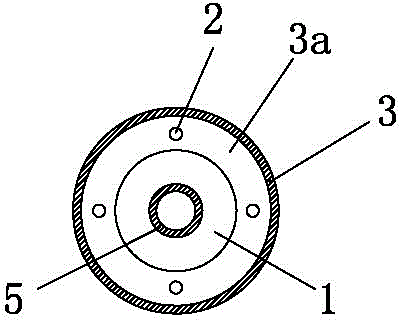

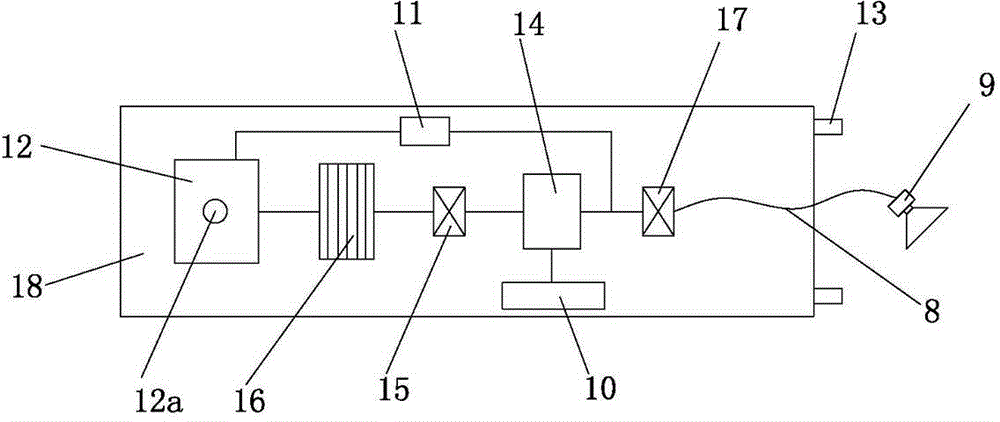

[0011] Depend on Figure 1-3 Given, the present invention includes an outer gun barrel, an inner gun barrel and an atomizing nozzle. The inner gun barrel 5 is installed in the center of the outer gun barrel 3, and one end extends out of the outer gun barrel 3, and one end of the extension is connected with the reducing agent inlet 7, and the other One end communicates with the inlet of the atomizing nozzle 1 installed at the end of the outer gun barrel 3, and the cavity between the outer wall of the inner gun barrel 5 and the inner wall of the outer gun barrel 3 constitutes a compression chamber for protecting the inner gun barrel. The air channel 5a, the end of the outer gun barrel 3 equipped with the atomizing nozzle has a compressed air outlet 2 communicating with the compressed air channel 5a, and the side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com