Preparation method of high-resolution chalcogenide optical fiber imaging beam

An optical fiber image transmission beam, high-resolution technology, applied in the direction of beam optical fiber, glass manufacturing equipment, glass fiber products, etc. The effect of strong sex, short production cycle and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the high-resolution chalcogenide optical fiber image transmission bundle of embodiment 1 comprises the following steps:

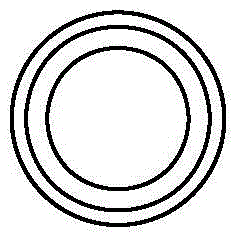

[0031] 1) Prepare a Ge with a diameter of Ф26mm and a core duty ratio of 65% with a PES film on the outer surface. 15 Sb 10 Se 75 The chalcogenide glass optical fiber preform is drawn stably and at a constant speed at 370°C by an optical fiber drawing machine in an inert gas atmosphere protection environment, and drawn into a chalcogenide glass optical fiber monofilament with a diameter of several hundred meters in the range of 250-330 μm. Structural diagram see figure 1 ;

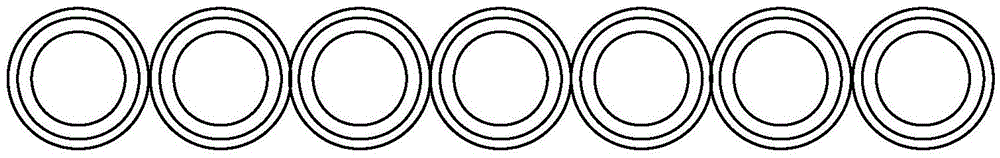

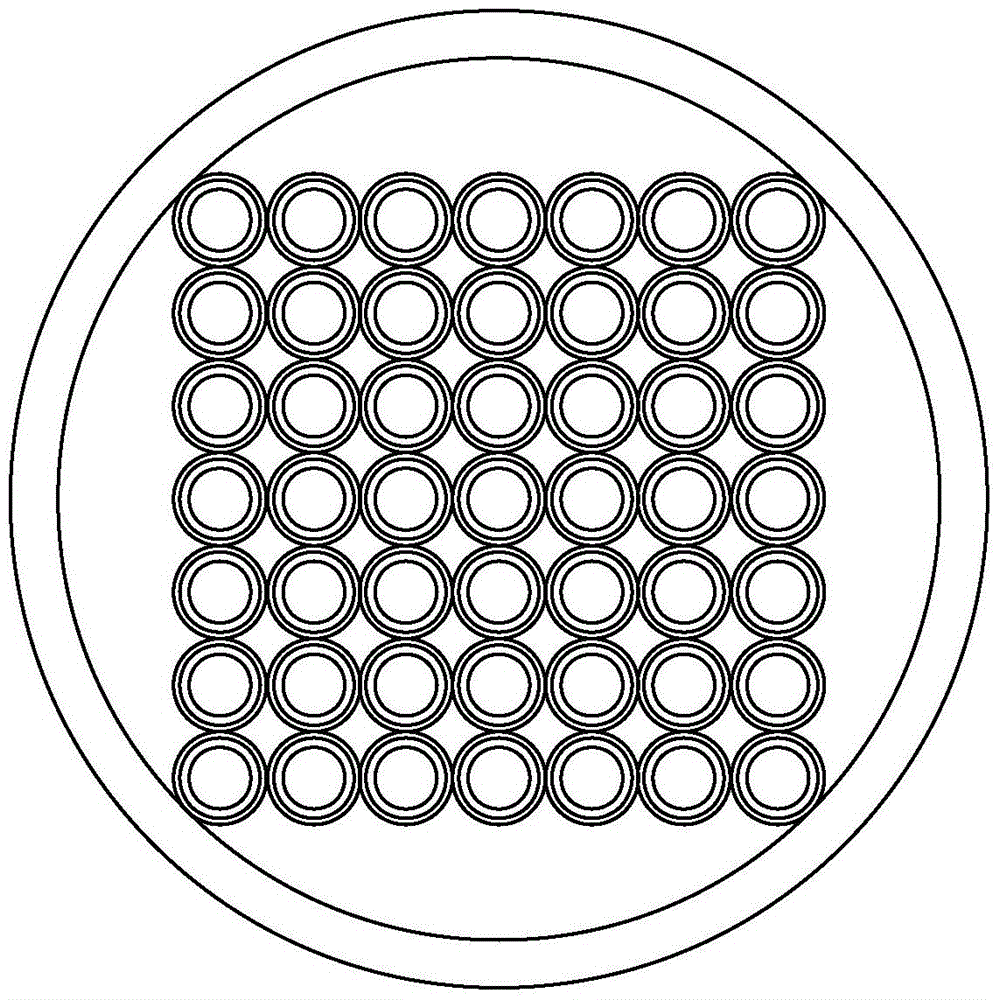

[0032] 2) Arrange the above-mentioned chalcogenide glass optical fiber monofilaments evenly and densely on the mold by using the wire winding method on the precision wire arranging equipment, forming a layer of chalcogenide glass optical fiber monofilaments on the surface of the mold, and then The outer surface of the glass fiber monofilament layer i...

Embodiment 2

[0035] The preparation method of the high-resolution chalcogenide optical fiber image transmission bundle of embodiment 2 comprises the following steps:

[0036] 1) Prepare a Ge with a diameter of Ф26mm and a core duty ratio of 65% with a PEI film on the outer surface. 15 Sb 10 Se 75 Chalcogenide glass optical fiber preform rods are drawn at a stable and uniform speed at 420°C by an optical fiber drawing machine in an inert gas atmosphere protection environment, and drawn into chalcogenide glass optical fiber monofilaments with a diameter of several hundred meters in the range of 250-330 μm. Structural diagram see figure 1 ;

[0037] 2) Arrange the above-mentioned chalcogenide glass optical fiber monofilaments evenly and densely on the mold by using the wire winding method on the precision wire arranging equipment, forming a layer of chalcogenide glass optical fiber monofilaments on the surface of the mold, and then The outer surface of the glass fiber monofilament layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com