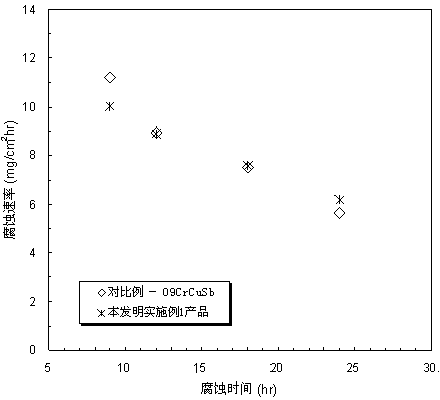

Steel plate resistant to sulfuric acid dew point corrosion and manufacturing method for steel plate

A technology of dew point corrosion and manufacturing method, applied in the direction of temperature control, etc., can solve problems such as inability to meet requirements, low yield ratio, etc., and achieve the effect of increasing yield strength, increasing strength, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The thickness of the sulfuric acid dew-point corrosion-resistant steel plate involved in this example is 32 mm, and its chemical composition is calculated by mass percentage: C: 0.07%, Si: 0.32%, Mn: 1.16%, P: 0.010%, S: 0.003%, Cr : 0.46%, Ni: 0.19%, Cu: 0.35%, Al: 0.028%, V: 0.026%, Nb: 0.032%, Ti: 0.013%, Ca: 0.0006%, N: 0.0059%, balance For iron and inevitable impurity elements.

[0038] The manufacturing process of the 32mm thick sulfuric acid dew point corrosion resistant steel plate is as follows: according to the chemical composition of the above sulfuric acid dew point corrosion resistant steel plate, the smelting raw materials are sequentially subjected to KR molten iron pretreatment, converter smelting, LF refining, and RH vacuum degassing to obtain high purity. The molten steel is then continuously cast into a continuous casting slab with a thickness of 150mm by the continuous casting machine. Heat the continuous casting slab to 1220°C and hold it for 2.5 h...

Embodiment 2

[0043] The thickness of the sulfuric acid dew point corrosion-resistant steel plate involved in this example is 19mm, and its chemical composition is calculated by mass percentage: C: 0.08%, Si: 0.38%, Mn: 1.07%, P: 0.011%, S: 0.002%, Cr : 0.52%, Ni: 0.25%, Cu: 0.40%, Al: 0.032%, V: 0.028%, Nb: 0.036%, Ti: 0.014%, Ca: 0.0009%, N: 0.0024%, and the balance is iron and unavoidable impurity elements.

[0044] The manufacturing process of the 19mm thick sulfuric acid dew point corrosion resistant steel plate is that the smelting raw materials are configured according to the chemical composition of the above sulfuric acid dew point corrosion resistant steel plate, followed by KR molten iron pretreatment, converter smelting, LF refining, and RH vacuum degassing to obtain high purity. The molten steel is then continuously cast into a continuous casting slab with a thickness of 150mm by the continuous casting machine. The continuous casting slab is heated to 1200°C and held for 2.2 ho...

Embodiment 3

[0048] The thickness of the sulfuric acid dew point corrosion-resistant steel plate involved in this example is 10mm, and its chemical composition is calculated by mass percentage: C: 0.06%, Si: 0.32%, Mn: 1.19%, P: 0.009%, S: 0.003%, Cr : 0.45%, Ni: 0.20%, Cu: 0.42%, Al: 0.034%, V: 0.031%, Nb: 0.036%, Ti: 0.015%, Ca: 0.0008%, N: 0.0036%, and the balance is iron and unavoidable impurity elements.

[0049] The manufacturing process of the 10mm thick sulfuric acid dew point corrosion resistant steel plate is that the smelting raw materials are configured according to the chemical composition of the above sulfuric acid dew point corrosion resistant steel plate, followed by KR molten iron pretreatment, converter smelting, LF refining, and RH vacuum degassing to obtain high purity. The molten steel is then continuously cast into a continuous casting slab with a thickness of 150mm by the continuous casting machine. The continuous casting slab is heated to 1200°C and held for 2.6 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com