Construction method of deep elevator shaft or water collection well

A construction method and the technology of collecting wells, which are applied in water conservancy projects, excavation, artificial islands, etc., can solve problems such as the inability to effectively curb the collection and infiltration of soil phreatic water, affect the quality of waterproof concrete molding, and cannot completely solve deep well templates, etc., to achieve reduction The difficulty of installation and dismantling, the improvement of construction quality, and the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

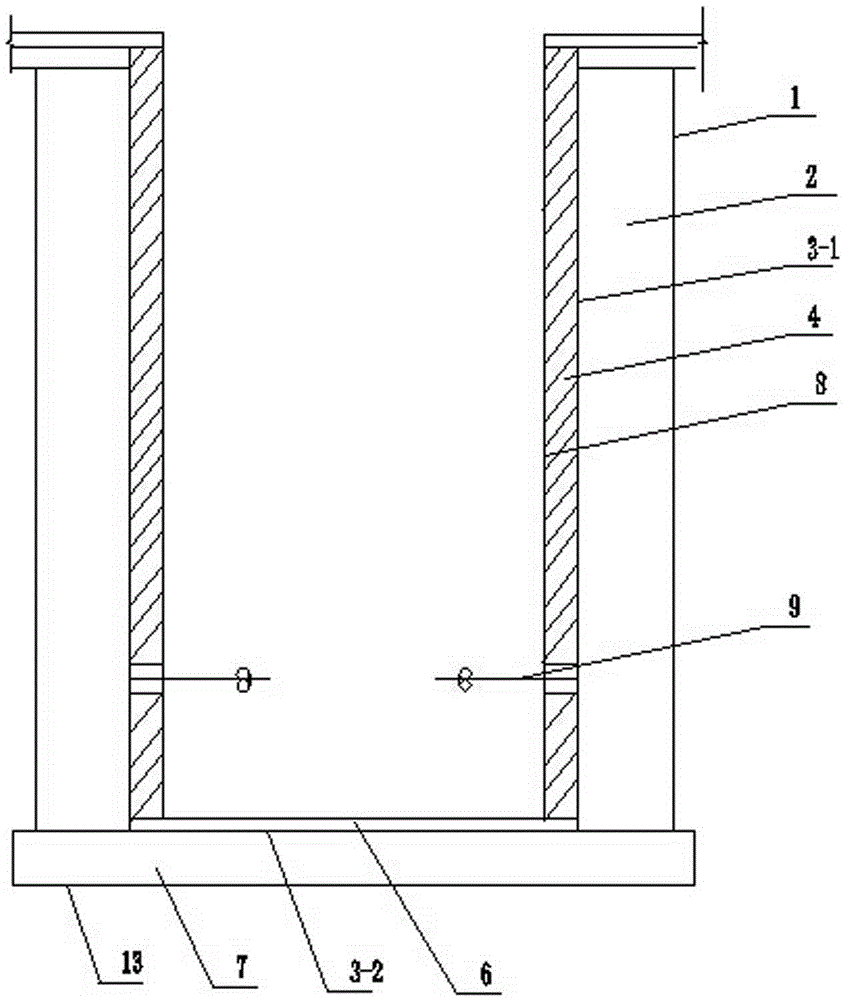

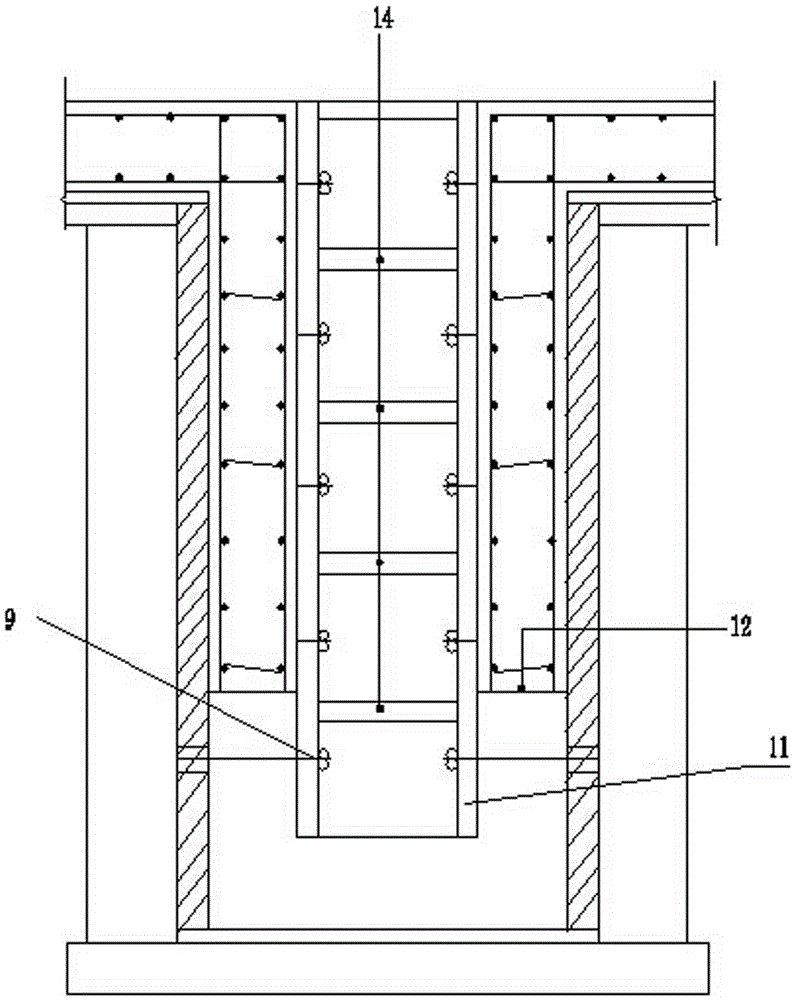

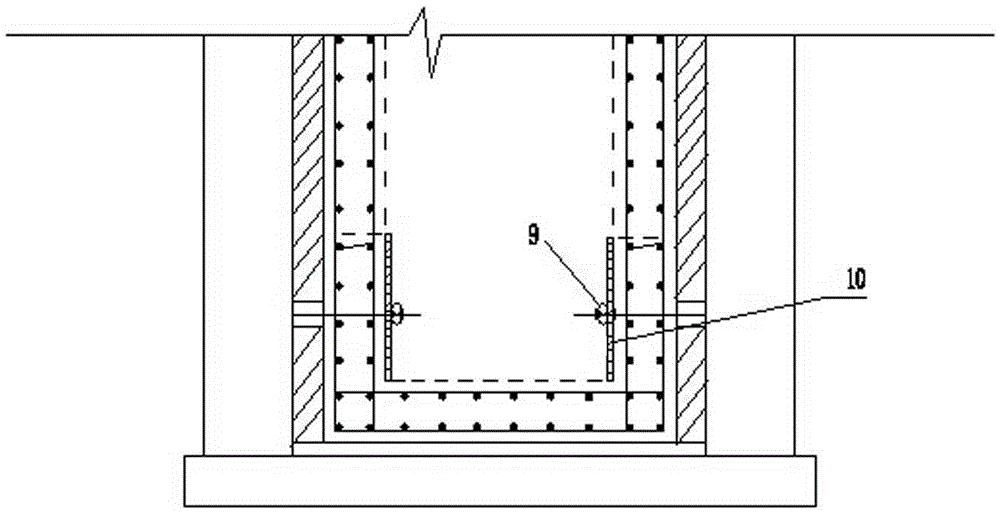

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] see Figure 1-Figure 3 , a relatively deep elevator shaft or water collection well construction method, comprising the steps of:

[0026] Step 1. After the earthwork of the foundation pit of the elevator shaft or water collection well is completed, construct the bottom of the foundation pit

[0027] (1) Make the bottom backfill plain soil layer 13 at the bottom;

[0028] (2) Make a plain concrete reinforcement cushion 7 on the bottom backfill plain soil layer 13;

[0029] (3) Set the bottom waterproof membrane layer 3-2 on the plain concrete reinforced cushion layer 7;

[0030] (4) Make a fine stone concrete protective layer 6 on the bottom waterproof membrane layer 3-2;

[0031] Step 2: Construction of the side wall of the foundation pit

[0032] (1) Make the side wall plain concrete membrane 2;

[0033] (2) Symmetrical manual backfilling and layered tamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com