Optical fiber one- and two-way bending curvature double-channel tracking monitor and monitoring method

A double-bending and tracking-monitoring technology, applied in the direction of optical instrument testing, instruments, measuring devices, etc., can solve the problems of inapplicability, low cost performance, unreasonable structure, etc., and achieve the effect of easy operation, low cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]The present invention will be further described below in conjunction with the accompanying drawings.

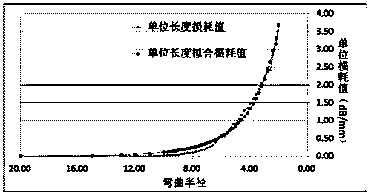

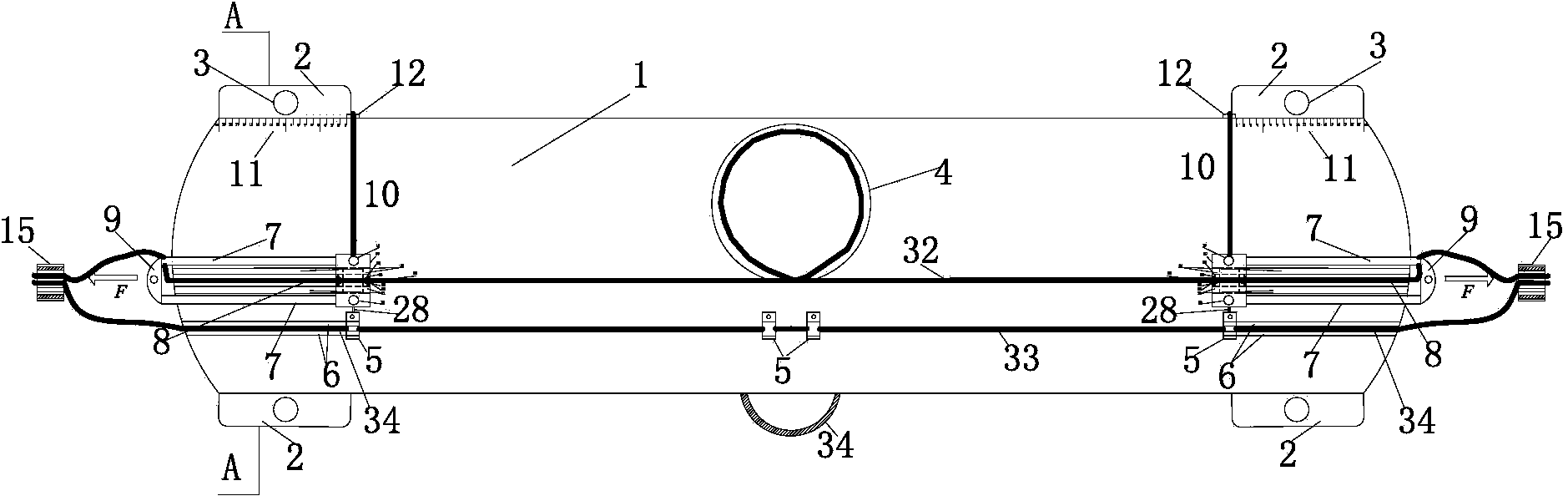

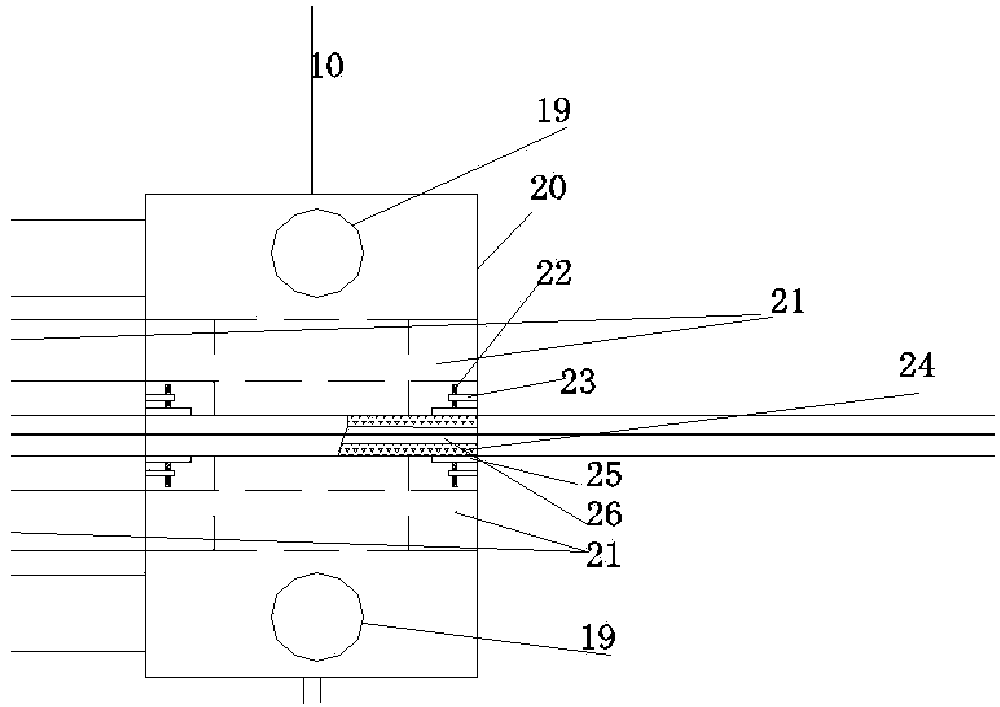

[0027] Such as Figure 1 to Figure 6 As shown, a dual-channel tracking monitor for optical fiber single- and bi-directional bending and curvature includes an optical fiber carrier 1, an optical fiber stressed mobile carrier 20 located at both ends of the optical fiber carrier 1, and an optical fiber stressed mobile carrier 20 at both ends. The bending pool 4 is provided with a scale scale on the bending pool 4, and the bending pool 4 is a circular surface sunken inside, so that the bending curvature of the test optical fiber 32 can be changed, and the circular surface of the internal depression communicates with the mobile carrier channel 26. The optical fiber stressed mobile carrier 20 is connected to the load-bearing end 9 through the force transmission shaft 7, and one side of the optical fiber stressed mobile carrier 20 is connected to the connecting rod dial 11 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com