In-situ test instrument for micromechanics performances of materials under three-point and four-point bending action

A four-point bending and micromechanics technology, which is applied to scientific instruments, using stable bending force to test the strength of materials, instruments, etc., can solve the problems of large volume, expensive cost and complex structure of test equipment, and achieve compact structure, reduce The effect of high friction and transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

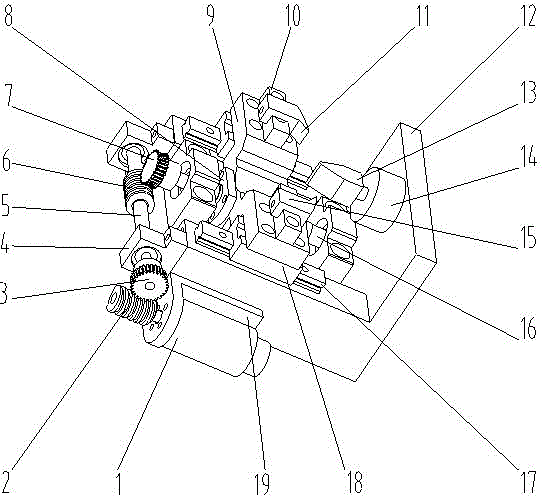

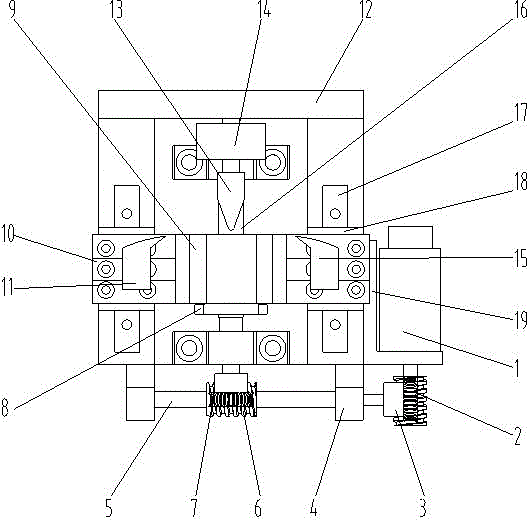

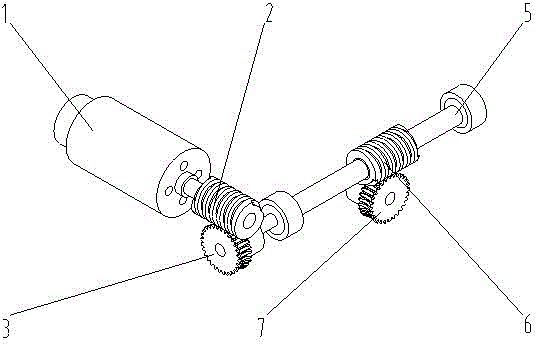

[0021] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0022] see Figure 1 to Figure 3 As shown, the in-situ test instrument for the micromechanical properties of materials under the action of three-point and four-point bending of the present invention includes a precision drive unit, a transmission and execution unit, a signal control and detection unit, a connection and a support unit, and the specific structure is: DC The servo motor 1 and the motor support 19 are installed on the base 12 through bolts, the worm a2 is fixed on the DC servo motor 1, the turbine a3 and the worm b6 are respectively installed on the shaft 5, both ends of the shaft 5 are fixed on the bracket 4, and the turbine b7 Installed on the lead screw 16 by screws, the lead screw 16 and the connecting plate a8 are connected to the sliding base 9 by screws, the connecting plate b10 and the elbows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com