Particulate matter mass concentration detector with self-purification system

A technology of mass concentration and particulate matter, which is applied in the direction of particle suspension analysis, measuring devices, scientific instruments, etc., can solve the problems of increasing the adsorption force of piezoelectric materials to dust particles and high cleanliness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

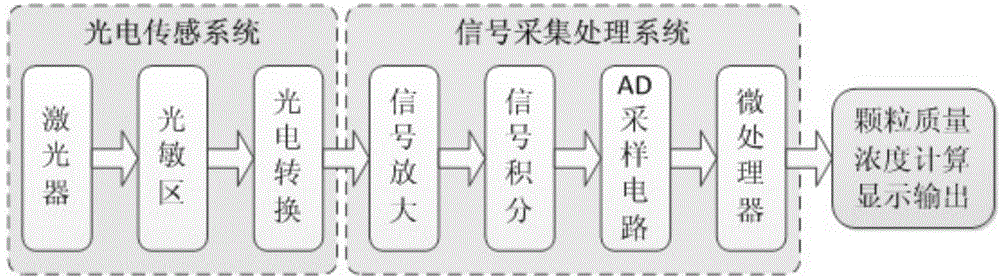

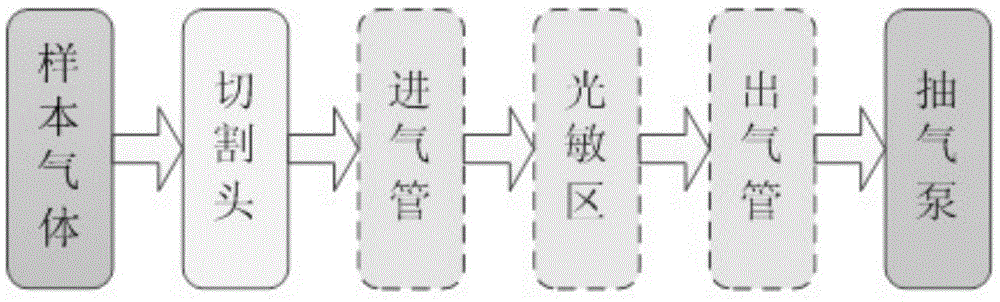

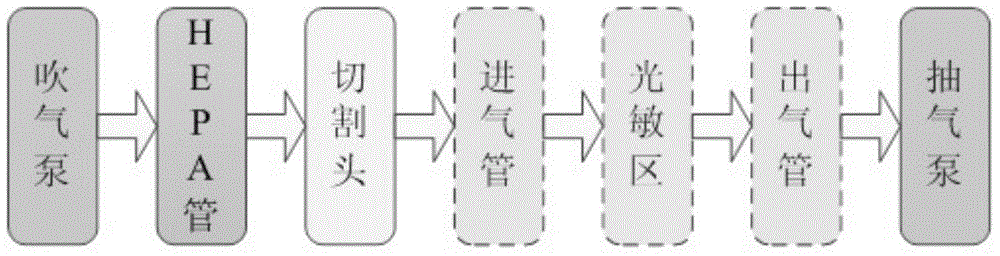

[0052] Such as Figure 4-6 Shown is a typical embodiment of the present invention, and the specific structure mainly includes an air blowing pump 1, a HEPA pipe 2, a tee 3, an air inlet assembly 5 located at the air inlet, a cutting head 4, a laser diode assembly 6, and a photodetector Component 9, an air outlet component 8 located at the gas outlet, a laser reflection bevel component 10, an air pump 11, a photosensitive area 7 and corresponding mechanical pipelines, etc., wherein an air inlet component 5, a cutting head 4, a laser diode component 6, a photoelectric The detector assembly 9, the gas outlet assembly 8, the laser reflection bevel assembly 10, and the photosensitive area 7 together form a photoelectric sensing system. The sampling gas passes through the tee 3, the cutting head 4, the air inlet pipe of the air inlet assembly 5, the photosensitive area 7 and the air outlet pipe of the air outlet assembly 8 to form a sampling air path, which may also include a flow m...

Embodiment 2

[0058] The basic structure of this embodiment is similar to that of the embodiment, except that the photodetector is a forward light scattering structure relative to the sampling gas path, that is, the laser beam and the photodetector are on the same line. In order to better accept the scattered light, it also includes a light absorption groove and a convex lens group located in front of the photodetector. The laser main beam is absorbed through the light absorption groove, and the scattered light is collected through the convex lens group integrated in the photodetector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com