Light-reflective anisotropic conductive adhesive and light-emitting device

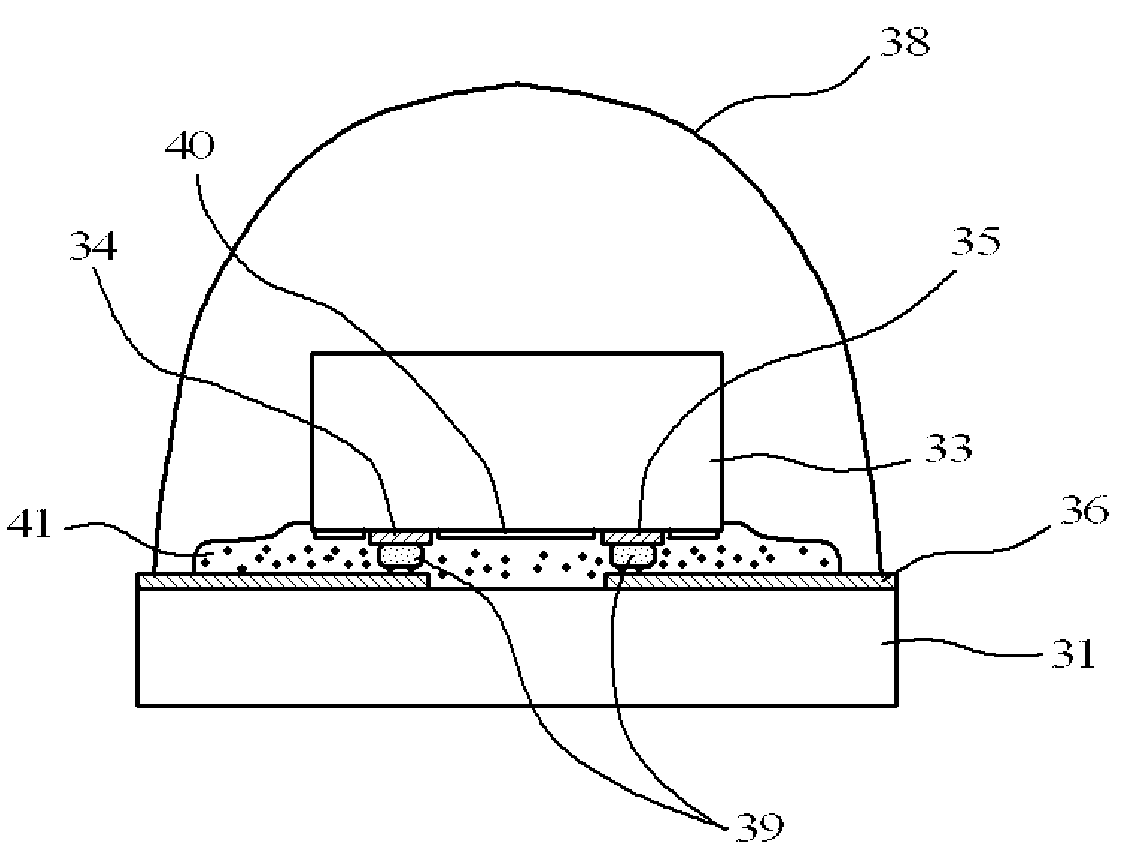

一种导电粘接剂、光反射性的技术,应用在导电粘合剂、胶粘剂、导电材料等方向,能够解决LED元件33发光效率降低等问题,达到波长依赖性小、提高发光效率、防止变色的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073]

[0074] The light-reflective anisotropic conductive adhesive of the present invention can be prepared by uniformly mixing the above-described light-reflective insulating particles, conductive particles, and thermosetting resin composition according to a conventional method. In addition, in the case of making a light-reflective anisotropic conductive adhesive film, it is only necessary to disperse and mix them with a solvent such as toluene, and apply it on a peeled PET film so that it has a desired thickness, at about 80 It can be dried at a temperature of about ℃.

[0075]

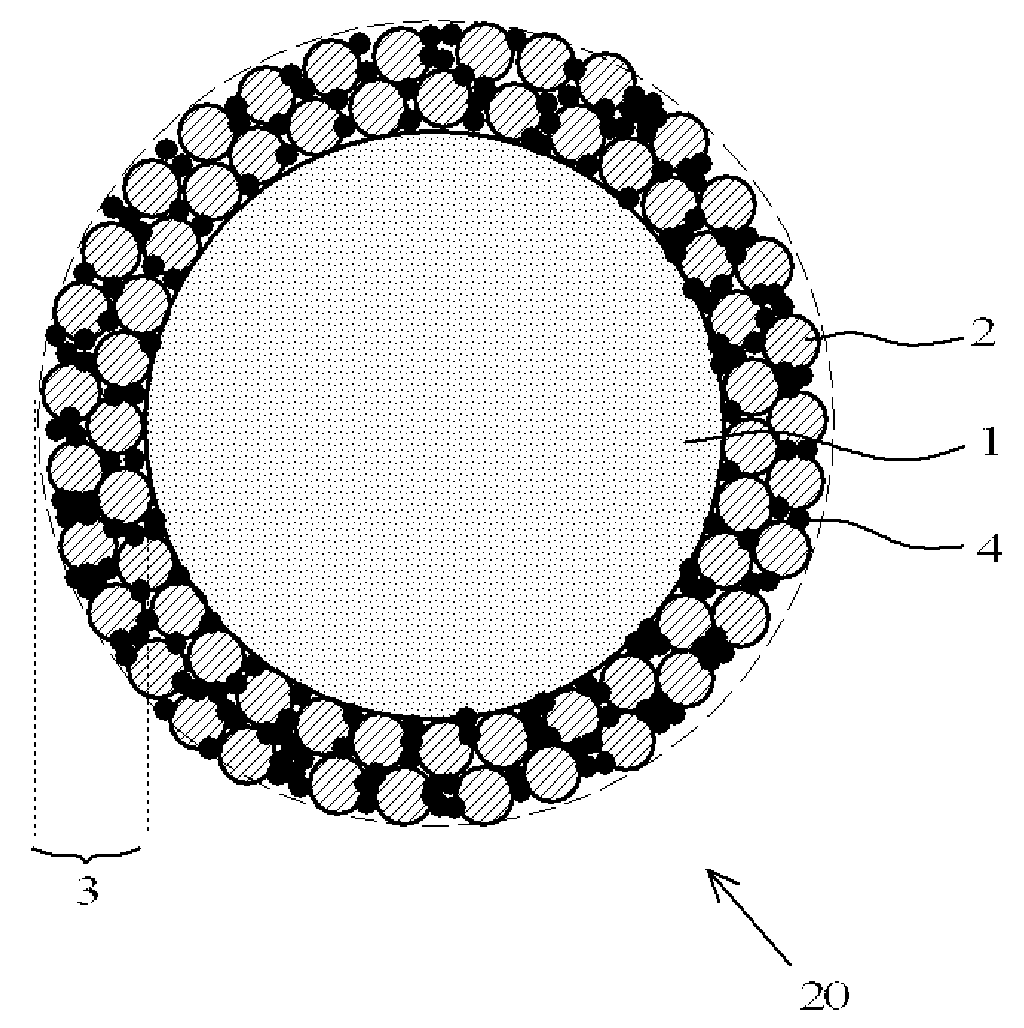

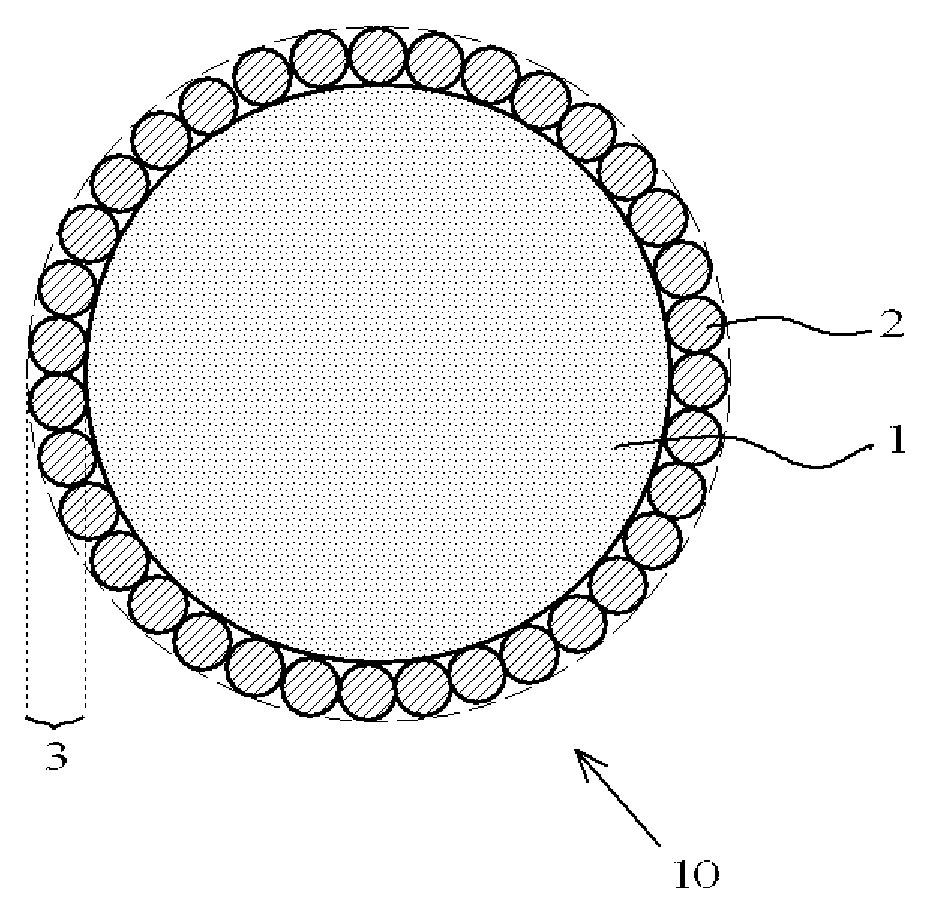

[0076] In order to improve the luminous efficiency of the light-emitting element, with regard to the reflective properties of the light-reflective anisotropic conductive adhesive of the present invention, it is desired that the cured product of the light-reflective anisotropic conductive adhesive has a reflectance of light with a wavelength of 450 nm ( JIS K7105) at least 30%. In order to obt...

Embodiment 1

[0087] Embodiment 1, comparative example 1-3

[0088] A light-reflective anisotropic conductive adhesive was prepared by uniformly mixing the components of the blend composition shown in Table 1.

[0089] It should be noted that, in Example 1, the epoxy compound and the acid anhydride curing agent were blended so that the ratio of the number of epoxy groups / acid anhydride functional groups was 1 / 1.1. In addition, the anisotropic conductive adhesive of Comparative Example 2 was obtained by mixing light-reflective insulating particles and conductive particles into a two-component curing type dimethyl silicone resin (IVS4742, Momentive Performance Materials Inc.). The anisotropic conductive adhesive of 3 is obtained by mixing light-reflective insulating particles and conductive particles with a two-component curing type phenyl silicone resin (SCR-1012, Shin-Etsu Chemical Co., Ltd.).

[0090]

[0091] (evaluate)

[0092] The wafer shear strength of the obtained light-reflective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com