Preparation and tensioning method of composite rib material

A composite reinforcement and tensioning technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problem of difficult basalt fiber reinforcement, and achieve the effects of good corrosion resistance, convenient processing and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

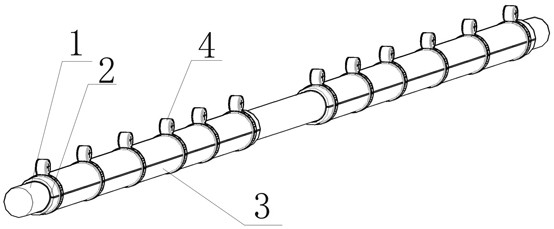

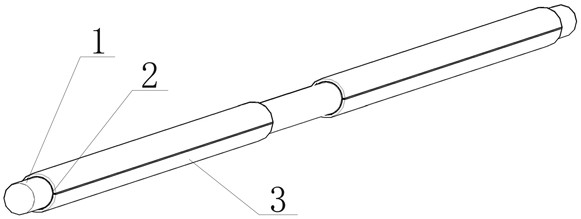

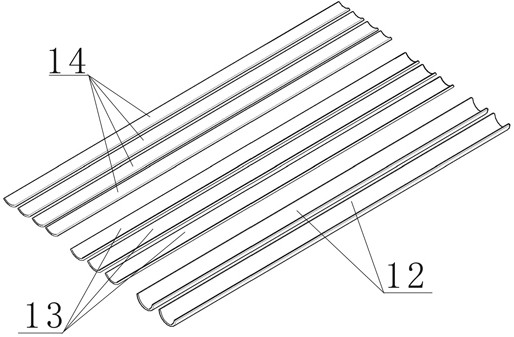

[0026] A method for preparing composite reinforcement, comprising basalt fiber reinforcement 1 and steel sleeves 3 arranged at both ends of the basalt fiber reinforcement 1, the steel sleeve 3 adopts 45 # Seamless steel pipe preparation, the inner diameter of the steel sleeve 3 is 13mm, the outer diameter is 15mm, the inner diameter of the steel sleeve 3 is equal to the outer diameter of the basalt fiber reinforcement 1, the specific preparation method of the composite reinforcement and the use of the composite reinforcement The specific method of stretching is: laser cutting the steel sleeve 3 in half along the axis into a two-petal steel sleeve 12, a three-petal steel sleeve 13, and a four-petal steel sleeve 14, and the width of the cutting seam is different. Less than 0.2mm, the steel casing 3 after cutting is relying on the impact force of high-speed sprayed steel grit to form a uniformly distributed rough surface on the inner and outer surfaces to increase friction, and us...

Embodiment 2

[0029] The untreated basalt fiber reinforcement 1 with a diameter of 13 mm was compared with the composite reinforcement of the two-lobed steel casing 12 with a longitudinal slit width of 1 mm prepared in Example 1 with the same diameter through tension experiments, wherein the untreated The basalt fiber reinforcement 1 directly stretches, and when the stress reaches 301MPa, the basalt fiber reinforcement 1 at 5 places of the anchor clip is cut; when the composite reinforcement of the two-lobed steel sleeve 12 prepared in the present invention is carried out in the tension test , when the stress reached 797MPa, it was broken from the middle of the composite reinforcement, which shows that the protection of the two-petal steel pipe sleeve 12 can effectively prevent the basalt fiber reinforcement 1 at the anchor clip 5 from being sheared during the tensioning process.

Embodiment 3

[0031] The anchor clips 5 were respectively installed on the middle part and the end of the two-petal steel casing 12 of the composite reinforcement prepared in Example 2. After the tension experiment was compared, when the stress reached 642 MPa, the anchor clip was installed at the end. The two-petal steel casing 12 of sheet 5 is degummed and slipped, but the two-petal steel casing 12 with anchor clip 5 installed in the middle does not appear to be degummed and slipped.

[0032] Implementation column 4

[0033] Respectively will adopt the model as 20 # Seamless steel pipe and embodiment 1 adopt model is 45 # The two-petal steel casing 12 with a longitudinal slit width of 1mm prepared from seamless steel pipes was compared with the tension test of the composite reinforcement prepared by the method in Example 1 through the anchor tension equipment. When the stress reached 602 MPa, due to 20 # The hardness of the steel casing is too low, and the steel casing and the basalt fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com