Novel epoxy group-containing siloxane compound

A technology of siloxane compound and epoxy group, which is applied in the field of new type of siloxane compound containing epoxy group, can solve the problems such as color change of emitted light, and achieve the effect of preventing discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

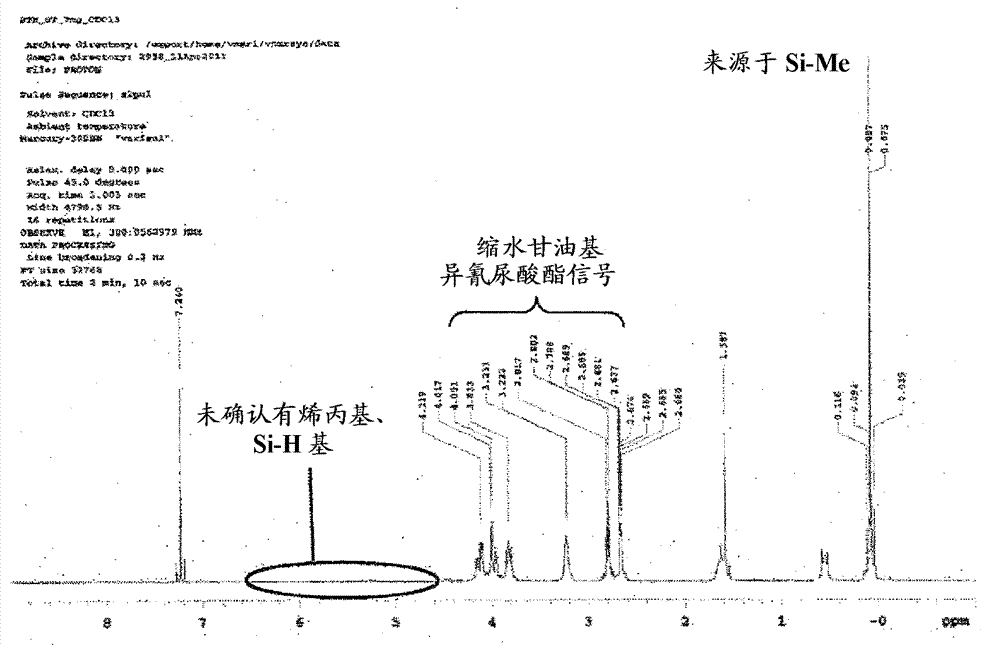

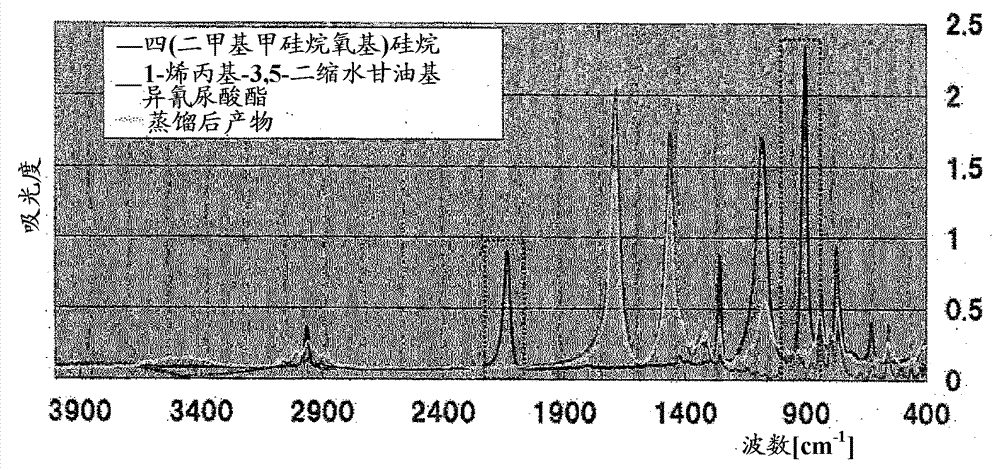

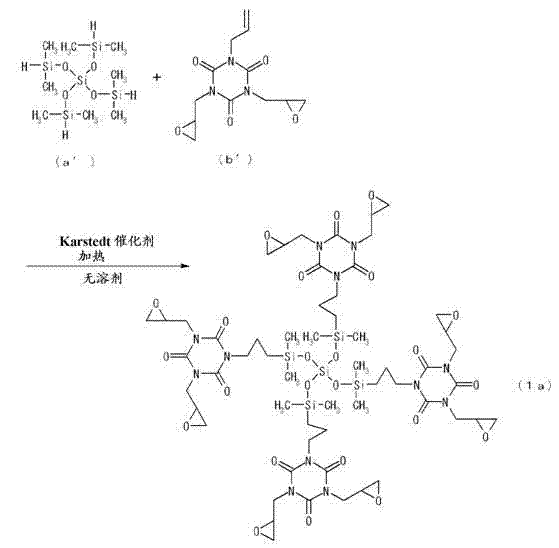

[0041] In a nitrogen stream, drop 28.37g (100.88mmol) of 1-allyl-3,5-diglycidyl isocyanurate (MADGIC, Shikoku Chemical Industry Co., Ltd.) and 6.63 g (20.17 mmol) of tetrakis(hydrogenated dimethylsiloxy) silane (SIT7273.0, Gelest Inc.), the mixture was stirred at 80° C. until uniformly melted. Next, 30.2 μL of a 2% Karstedt catalyst solution (xylene solution) was added to the molten mixture, heated to 120° C. while stirring, and after the temperature of the molten mixture reached 120° C., the temperature was maintained for 9 hours. 1-allyl-3,5-diglycidyl isocyanurate and tetrakis(hydrodimethylsiloxy)silane were reacted.

[0042] After completion of the reaction, the reaction mixture was cooled, and unreacted monomers were distilled off under reduced pressure (150° C. / 0.1 kPa) to obtain an epoxy group-containing siloxane compound of formula (1a).

[0043]

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com