Preparation method of formaldehyde-photodegrading honeycomb activated carbon

A technology of honeycomb activated carbon and photodegradation, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc. It can solve the problems of inhibiting commercial production, low adsorption capacity, increasing catalyst cost and environmental load, and achieves good catalytic degradation. High performance, good adsorption performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

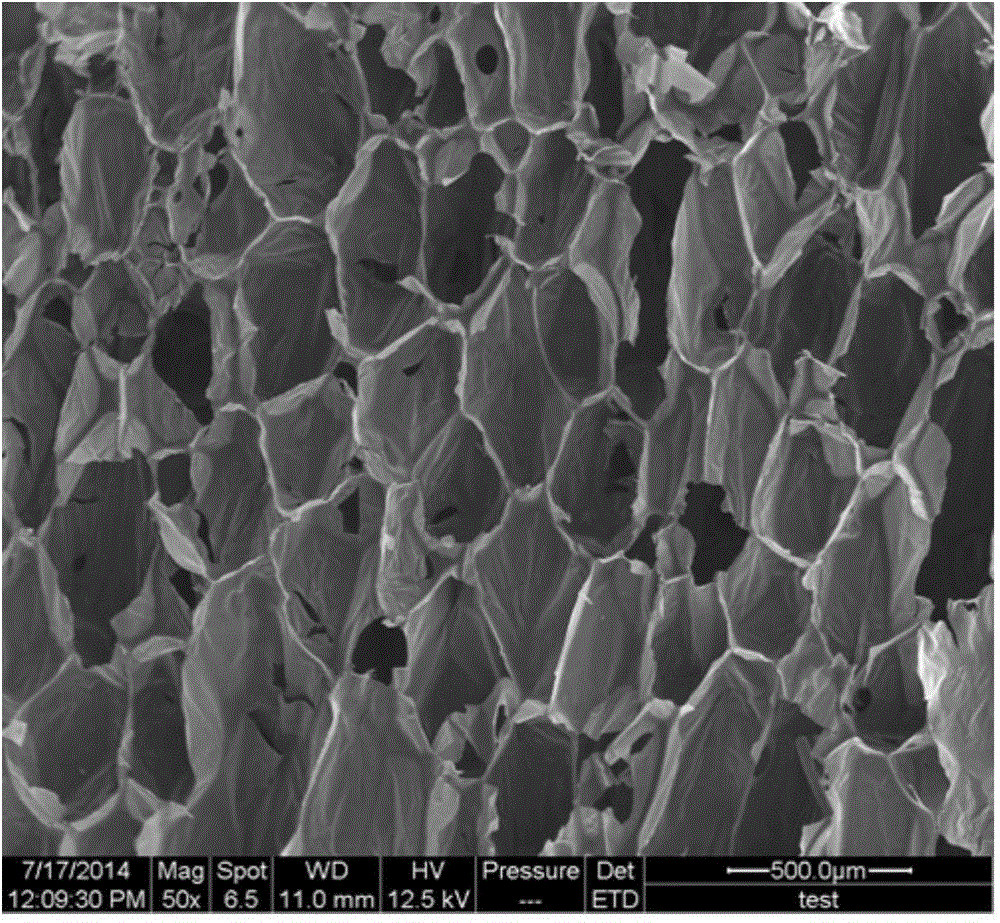

[0024] Add 10.0g black material (polyether 4110 of 5 parts, the hard foam silicon oil of 0.2 part, the water of 0.08 part, the pentamethyldiethylene triamine of 0.006 part, the dichlorofluoroethane of 4 parts in the cellophane mold, 0.2 parts of the mixture of cycloethylamine), 2.0g powdered activated carbon, after stirring for 60s at a rotating speed of 150r / min, add 7.0g white material, increase the rotating speed to 600r / min until it foams freely, and make it mature at room temperature for 12h Shaped, placed in a muffle furnace for heat treatment at 350 ° C for 1 hour to obtain honeycomb activated carbon.

[0025] P-25 TiO 2 Nanoparticles are ultrasonically dispersed to make a suspension with a concentration of 1%. The above-mentioned honeycomb-shaped activated carbon is soaked in the suspension for a period of time, and heat-treated in an oven until completely dry to obtain a P-25 / activated carbon composite material.

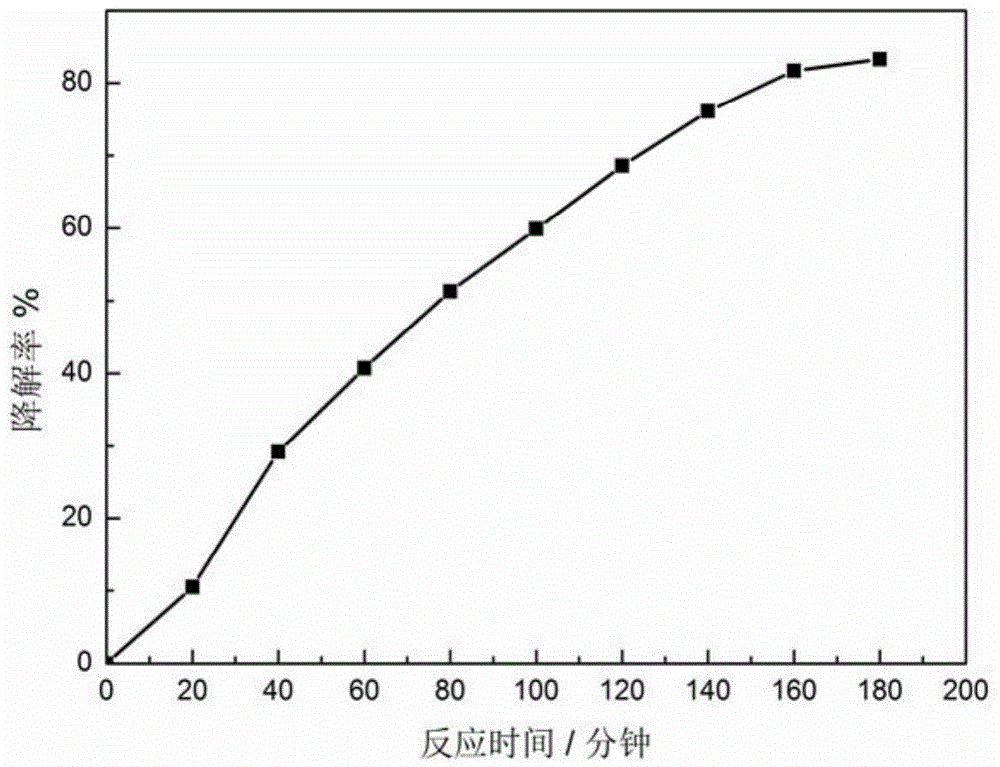

[0026] Hang the prepared P-25 / activated carbon compos...

Embodiment 2

[0028]Add 10.0g black material (6 parts of polyether 4110, 0.1 part of hard foam silicone oil, 0.08 part of water, 0.008 part of pentamethyldiethylenetriamine, 4 parts of dichloromonochloroethane, 0.2 parts of the mixture of cycloethylamine), 4.0g powdered activated carbon, after stirring for 50s at a rotating speed of 200r / min, add 9.0g white material, increase the rotating speed to 500r / min until it foams freely, and make it mature after 20h at room temperature. Shaped, placed in a muffle furnace for heat treatment at 450 ° C for 1 hour to obtain honeycomb activated carbon.

[0029] P-25 TiO 2 Nanoparticles are ultrasonically dispersed to make a suspension with a concentration of 1.5%. The above-mentioned honeycomb-shaped activated carbon is soaked in the suspension for a period of time, and heat-treated in an oven until completely dry to obtain a P-25 / activated carbon composite material.

[0030] Hang the prepared P-25 / activated carbon composite material in the laboratory-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com