Cleaning device for integral driving generator part accessory and cleaning method of integral driving generator part accessory

An integral drive and cleaning device technology, applied in the direction of cleaning methods using gas flow, cleaning methods using liquid, cleaning methods and utensils, etc., can solve the problems of non-compliance with environmental protection requirements, incomplete cleaning, large water consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

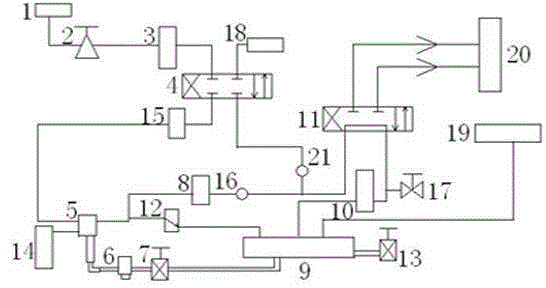

[0058] The main structure of this embodiment is a cleaning device that drives the accessories of the generator part as a whole, such as figure 1 As shown, the device includes a cleaning water tank 9, an air regulating valve 2, an air-driven hydraulic pump 5, an air three-position four-way valve 4, a hydraulic three-position four-way valve 11, a one-way valve I21, a one-way valve II16, and an overflow valve 12 and gas source generator 1;

[0059] The air outlet of the air source generator 1 is connected to the inlet of the compressed air filter 3 through the air regulating valve 2, and the compressed air filter 3 is connected to the air three-position four-way valve 4 and the one-way valve I21 in turn through the cleaning air pipeline. The valve I21 is connected to the flushing part 20 through the flow three-way four-position valve 11;

[0060] Air three-position four-way valve 4 is also connected with air-driven hydraulic pump 5, and air-driven hydraulic pump 5 is connected w...

Embodiment 2

[0093] This embodiment is further limited on the basis of Embodiment 1. The bottom end of the cleaning water tank 9 is equipped with a water tank drain valve 13, and the outer wall of the cleaning water tank 9 is provided with a liquid level display device. When the cleaning water tank 9 is cleaned, the liquid in it can be completely emptied through the water tank drain valve 13. At the same time, when the cleaning parts are cleaned with cleaning water, the current liquid level of the cleaning water tank is displayed by the liquid level display device, and water is added. Prompt, solution volume indication. Other parts of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

Embodiment 3

[0095] In this embodiment, on the basis of the above-mentioned embodiments, it is further defined that the air-driven hydraulic pump 5 is connected with an oil injection device 14, and a filter III15 is provided between the air-driven hydraulic pump 5 and the air three-position four-way valve 4. The setting of IIII5 realizes the re-filtering of the liquid cleaning water, removes impurities therein, so as not to bring secondary pollution to the flushing parts; a filter II6 is arranged between the air-driven hydraulic pump 5 and the inlet ball valve 7 of the air-driven hydraulic pump, Filter II6 mainly filters the cleaning water in the cleaning water tank, which can improve the quality of the cleaning water, reduce the impurities in the cleaning water, and realize the circular cleaning of the cleaning water; repeat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com