Elbow precise casting mold

A technology of precision casting and pipe bending, applied in the field of casting molds, which can solve problems such as displacement, low productivity, and water-soluble core breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

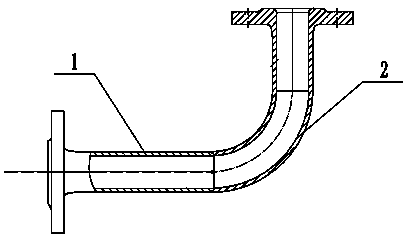

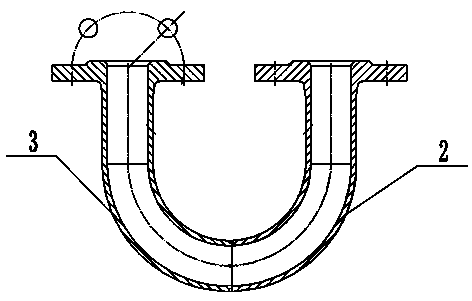

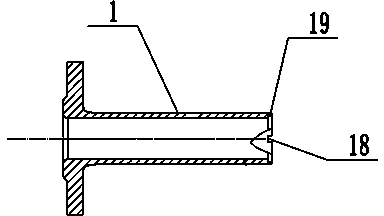

[0040] The invention is suitable for making wax pieces during precision casting of LB90° flanged pipes and U-shaped flanged pipes. The wax piece is designed as a separate structure with positioning left and right elbows, and is manufactured separately by means of circular rotating core pulling. Finally, the wax piece is positioned, assembled and welded twice by the left and right elbows. see figure 1 , image 3 and Figure 4 , The LB90° flange elbow is divided into a straight pipe flange 1 on the left half and a right elbow flange 2 on the right half. The side wall of the stop hole is provided with a square key groove 19, and the end surface corresponding to the right elbow flange 2 is provided with a stop 28 structure inserted into the stop hole 18, and the position of the outer surface of the stop 28 is matched with the square key slot 19 The squar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com