Self-climbing maintenance robot for wind power generation tower

A self-climbing and robotic technology, applied in cranes and other directions, can solve the problems of inconvenient maintenance and large crane rental costs, and achieve the effects of reducing maintenance costs, convenient installation and transportation, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

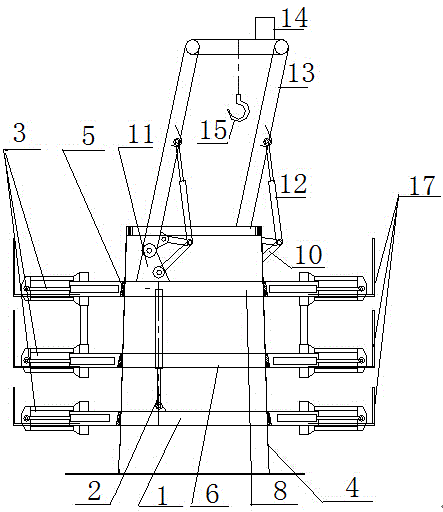

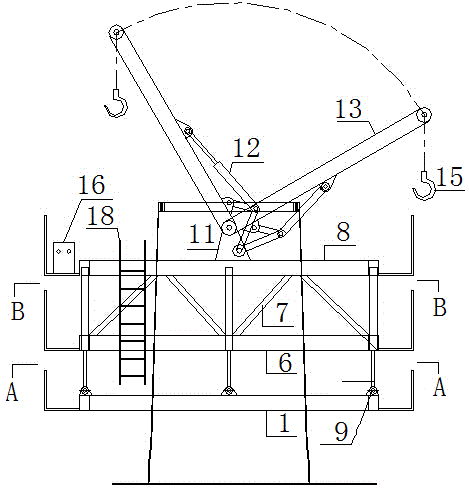

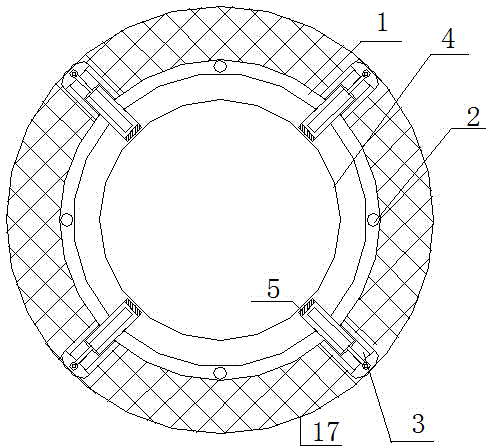

[0024] refer to Figure 1-Figure 6 , the wind power tower self-climbing maintenance robot of this embodiment includes a climbing mechanism and a hoisting mechanism, the hoisting mechanism is installed above the climbing mechanism, and the climbing mechanism includes a ring beam arranged in parallel up and down, and the ring beam is provided with three layers : including the upper ring beam 8 on the top layer, the lower ring beam 6 in the middle and the climbing ring beam 1 on the bottom layer, the three-layer ring beams are connected by a vertically arranged jacking cylinder 2, and the jacking cylinder 2 is provided with jacking cylinder ears There are 4 jacking cylinders 9 and 2 evenly arranged along the circumference of the ring beam, a ladder 18 is arranged between the ring beams of three layers, and the upper ring beam 8 and the lower ring beam 6 are fixedly connected by a support plate 7 . All be provided with annular construction platform 17 on the three-layer ring beam,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com