Telescopic tempering device

A tempering device, telescopic technology, applied in the direction of heat treatment equipment, furnace, heat treatment furnace, etc., can solve the problems that the expected tempering effect cannot be achieved, the mechanical properties cannot meet the requirements, and the quality cannot be controlled, so as to achieve temperature uniformity , good thermal insulation and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

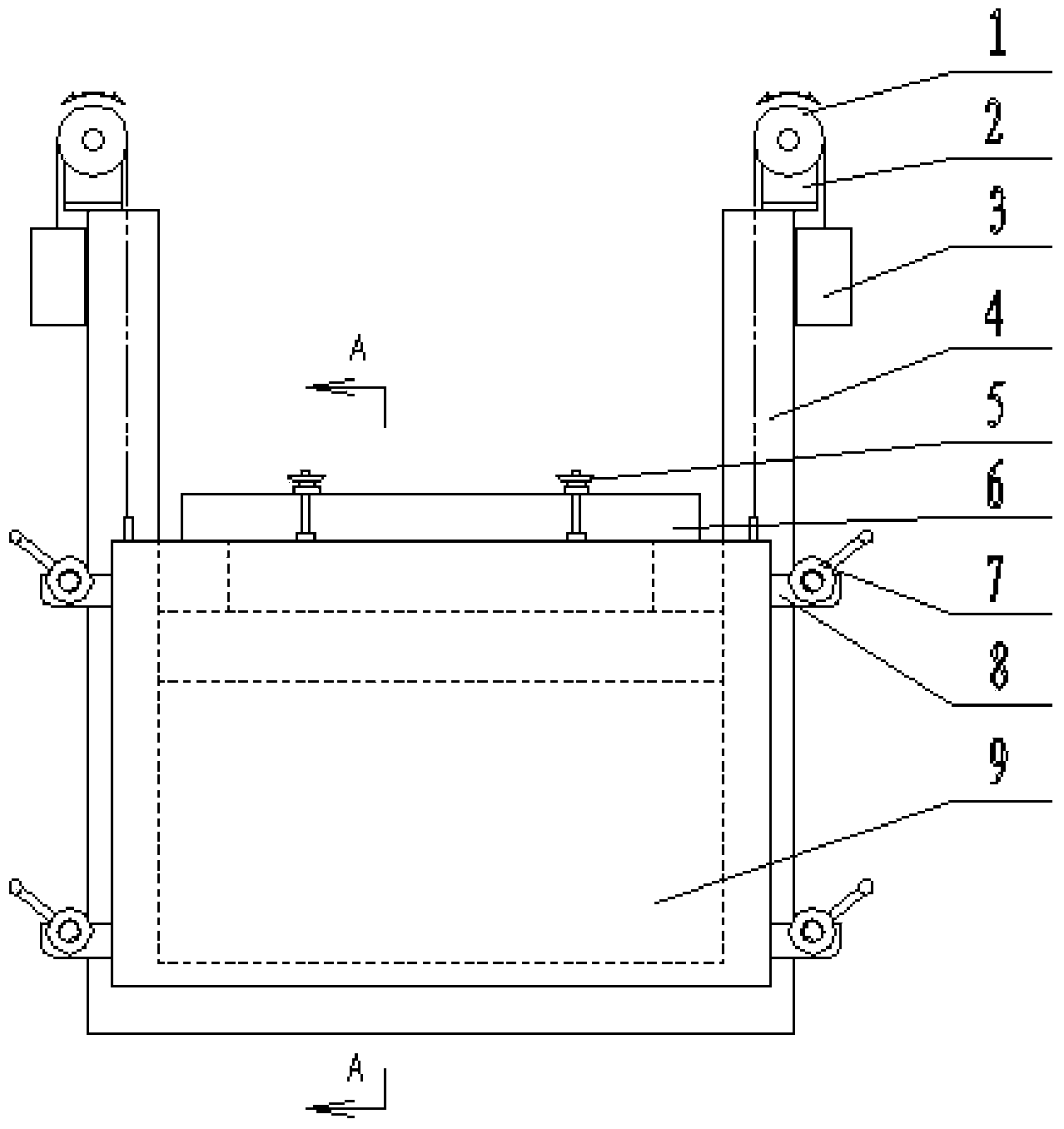

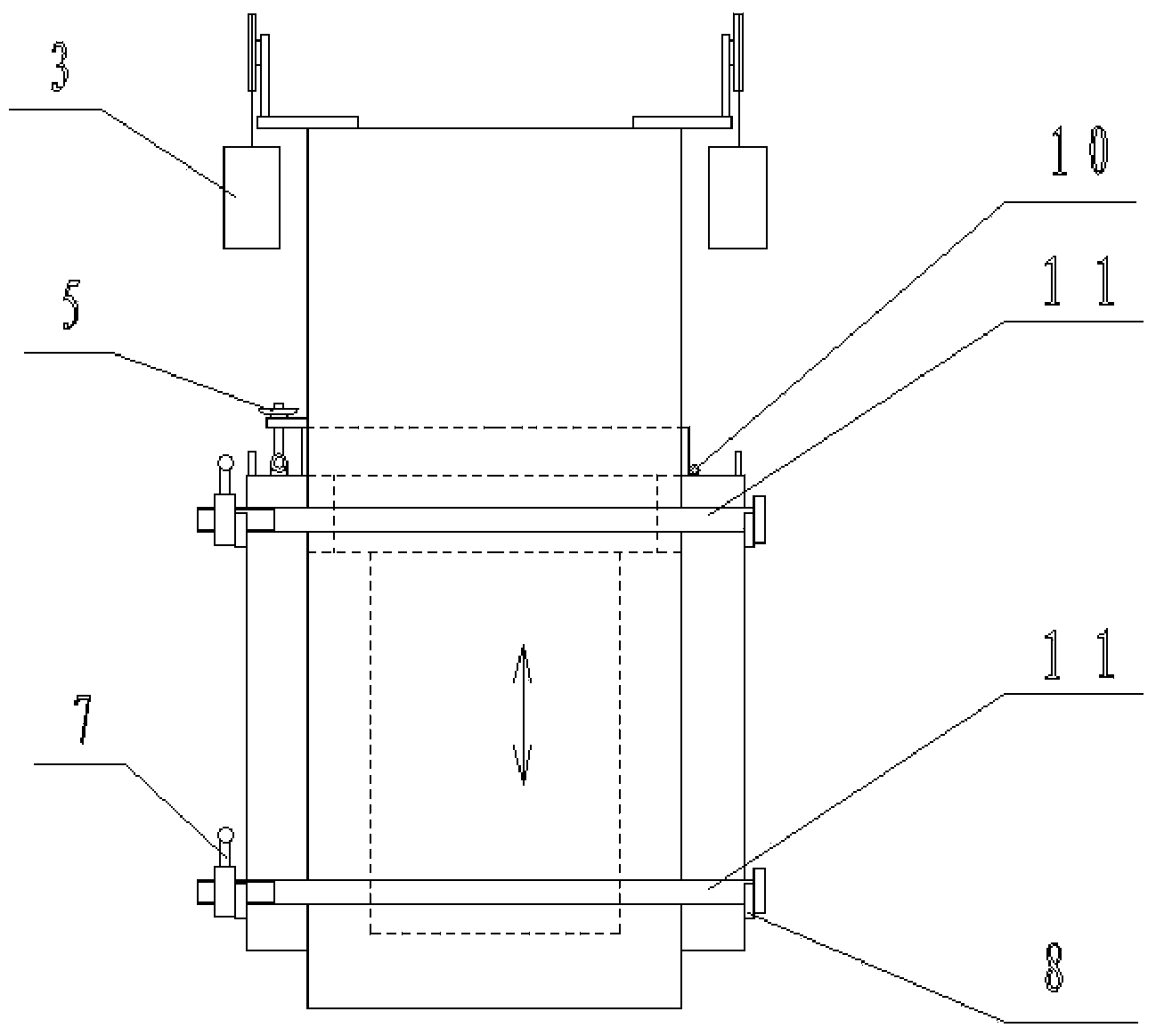

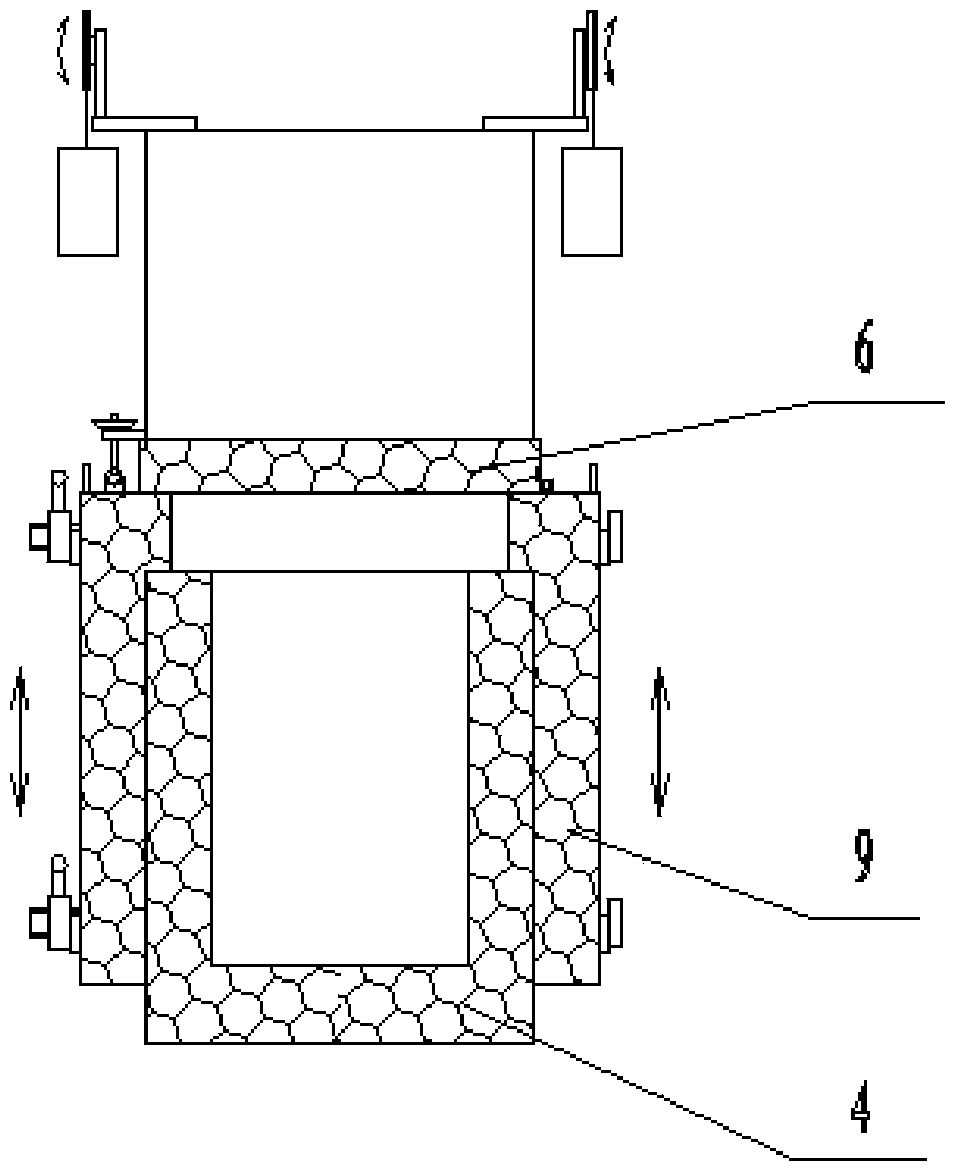

specific Embodiment

[0043] A ring with a diameter of 2000mm and a wall thickness of 40mm is pre-surface induction hardened and tempered. The existing technology can meet the requirements of induction hardening, but the largest tempering equipment size is 1000*2000*1000mm, which cannot meet the tempering requirements. At this time, the present invention can be used to temper the above-mentioned workpiece. The working process of this example is: after the operator manually loosens each lock nut 7, drags the box body B9 to the set position, locks the loosened lock nuts 7, opens the cover 6 and puts the workpiece into In the casing A4, then close the cover 6, lock the cover lock 5, after checking, start the furnace body heating device to complete the processing technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com