Shaft-simulating multifunctional flowing test system

A multifunctional testing and simulating wellbore technology, applied in measurement, wellbore/well components, earthwork drilling and production, etc., can solve problems such as inability to make full use of simulated string equipment, inability to inject liquid, and difficult adjustment of wellbore size parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

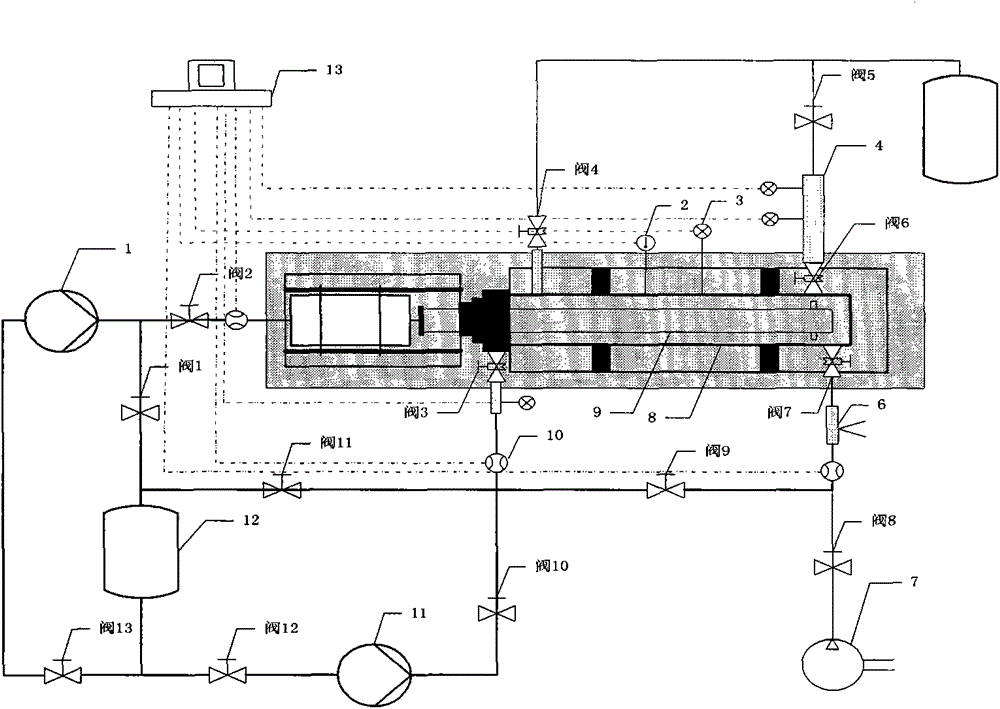

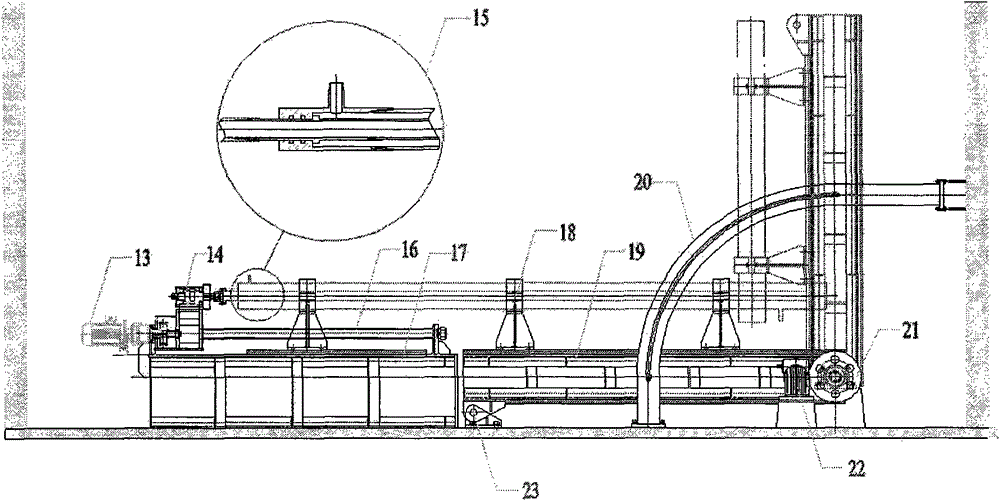

[0026] like figure 1 , figure 2 As shown, the multifunctional wellbore simulation test device mainly includes a liquid storage tank 12, a plunger pump 1 connected to the center pipe, a plunger pump 11 connected to the annular space, an electric motor 14 for controlling axial movement and rotation, and a Central pipe 15 for hydraulic swivel tap, small wellhead device 24, high-strength glass casing 8, central pipe for simulating oil pipe 9, crack simulator 4 for simulating crack existence, air compressor 7 for simulating formation gas intrusion, control data acquisition and processing Data controller 13, waste liquid tank 11, several flow, temperature, pressure sensors such as devices such as 2, 3, 10. Among them, the plunger pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com