Novel hypersonic missile outer-layer wind turbine blade heat preventing and cooling technology

A technology of wind rotor blades and missiles, used in wind power generation, self-propelled bombs, wind turbines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

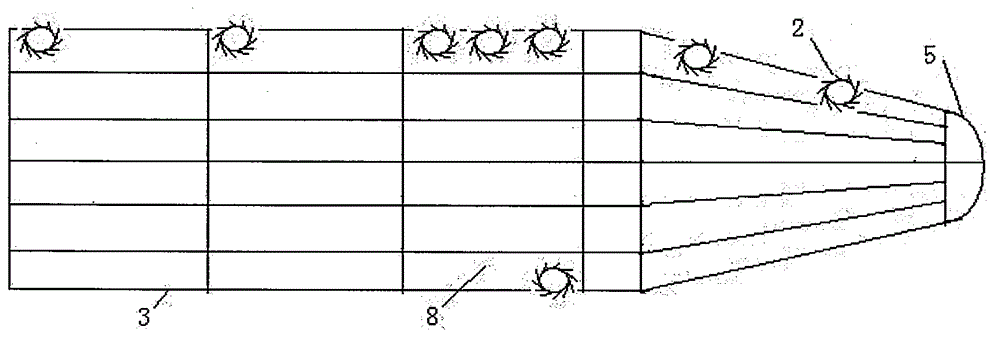

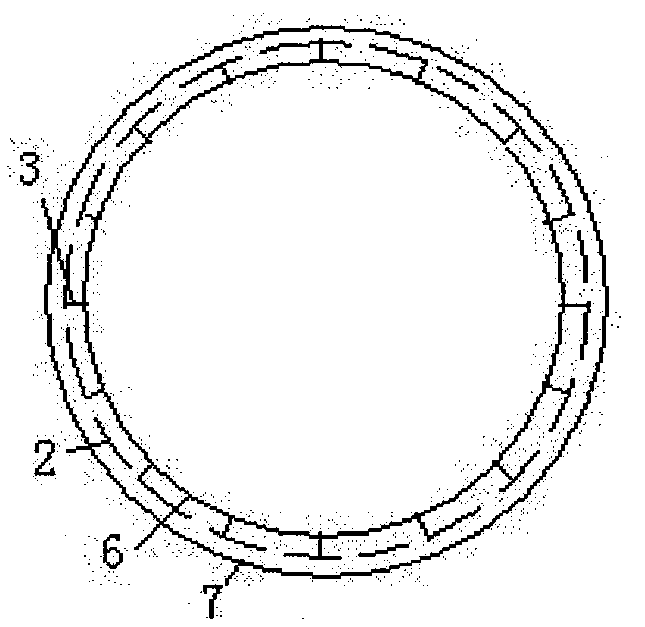

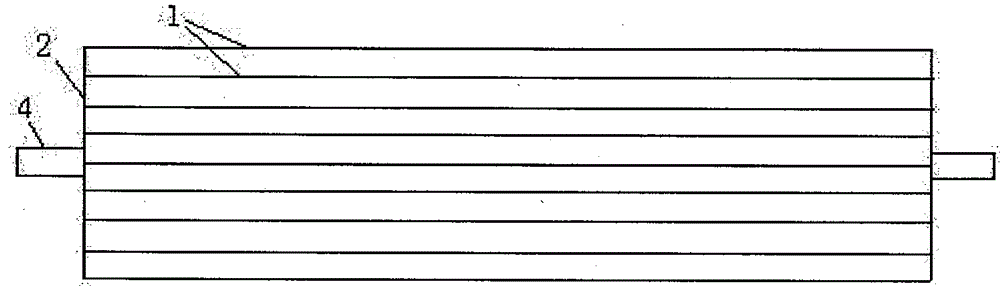

[0014] In the figure, 1 blade, 2 wind rotors, 3 wheel frames, 4 wheel axles, 5 warheads, 6 missile bodies, 7 outer diameters of blades, and 8 wheel grids.

[0015] 1. The blade is fixed on the cylindrical body of the 2. wind wheel at an oblique angle, and rotates against the impact of high-speed airflow. 2 wind wheels, consisting of a cylinder and 4 axles, with 1 blade on it, with a diameter of several centimeters and a cylinder length of N centimeters. It is installed in 8 wheel grids, and the blades rotate against the wind to perform work, blowing cold air to the outer layer of the missile to cool down and discharge Heat from the missile. The 3-wheel frame is fixed on the outer layer of the missile. There are countless 8-wheel grids, and each wheel grid is equipped with multiple 2-wind wheels. 4 axles are inserted in the holes of the 8 wheel grids at the center of the two ends of the cylinder and rotated. 5 warheads, missile warheads. 6 Missile body, built-in engine, engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com