Transmission assembly with integrated reverse gear

A reverse gear and assembly technology, applied in the field of transmission assembly, can solve the problems of incompact transmission installation, manufacture and use, affecting the installation of the whole vehicle, poor stability, etc., and achieve reasonable and compact internal layout, avoid interference, and save component costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

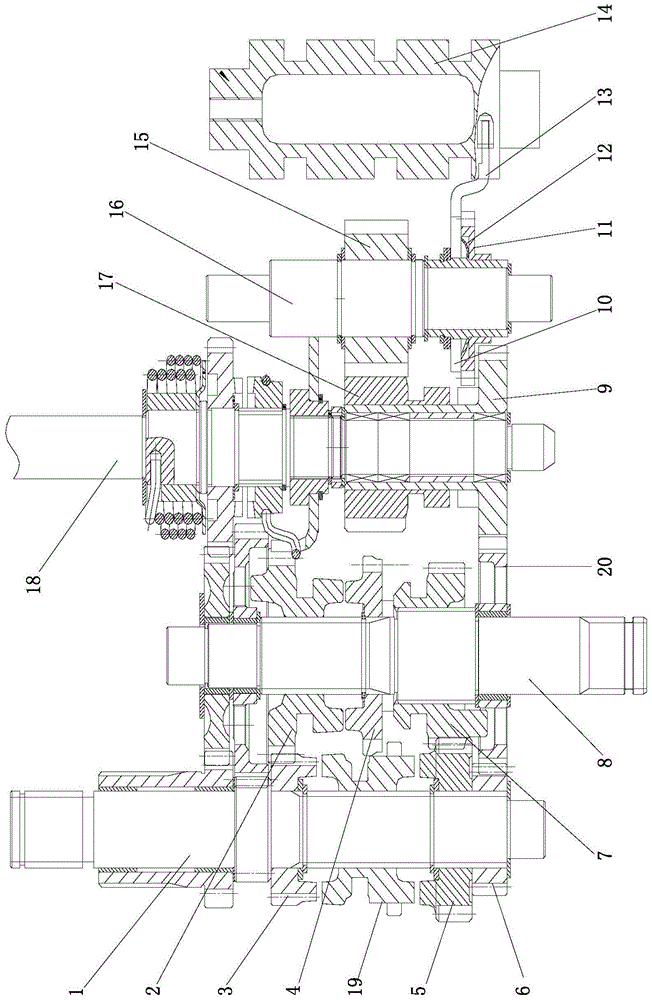

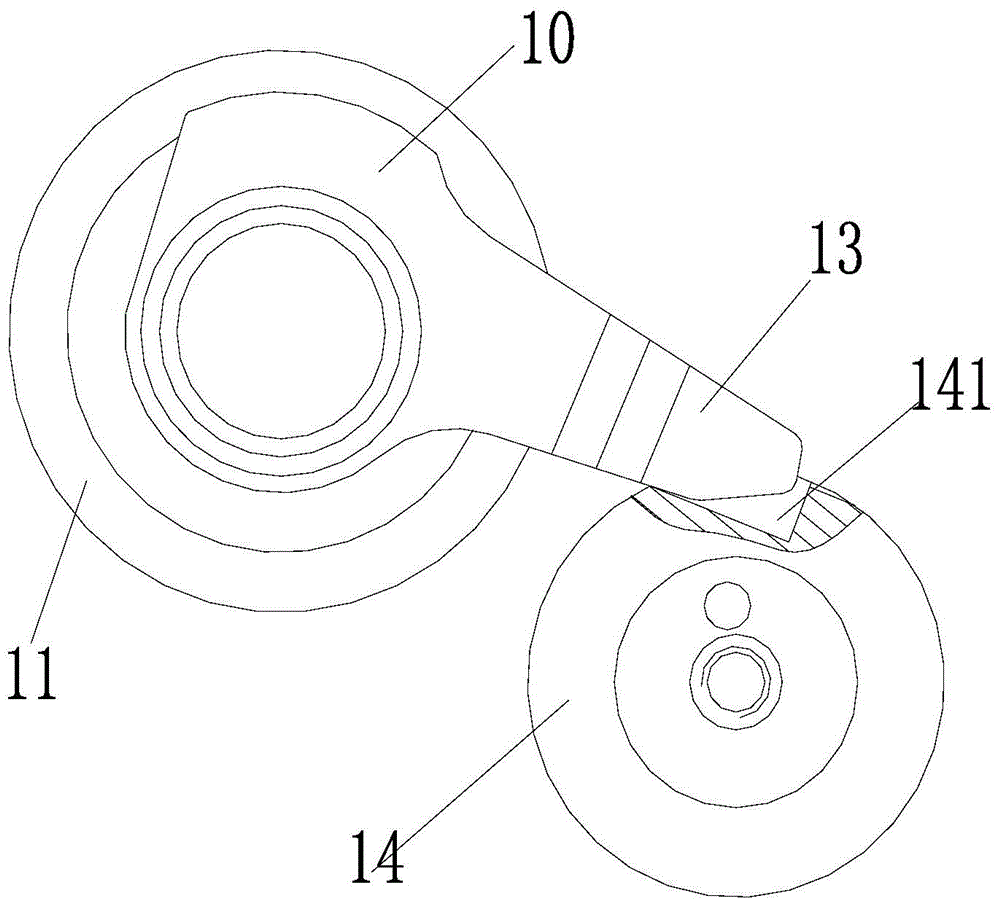

[0024] figure 1 It is a schematic diagram of the unfolded structure of the present invention, figure 2 It is a schematic diagram of the reverse gear limit mechanism, as shown in the figure: the transmission assembly with integrated reverse gear in this embodiment includes a power input shaft, a power output shaft that cooperates with the gear transmission of the power input shaft, a reverse gear transmission chain and a shared slave driven gear; the reverse transmission chain can be engaged with the drive or separated from the way to cooperate with the common driven gear;

[0025] As shown in the figure, in this embodiment, the reverse transmission chain includes a dual reverse drive gear and a common driven gear 4;

[0026] The double-connected reverse drive gear includes an input reverse drive gear 9 and an output reverse drive gear 17 that can be engaged with the input reverse drive gear 9 for transmission, and the engaging mode can be realized by axial sliding of an adap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com